Introduction

Lentivirus production plays a crucial role in modern biotechnology and medical research. It enables the delivery of genetic material into target cells, facilitating various applications in gene therapy, vaccine development, and basic research. In this comprehensive guide, we'll delve into the intricacies of lentivirus production, exploring techniques, optimization strategies, and FAQs to equip you with the knowledge needed for successful lentivirus-based experiments.

Lentivirus Production Techniques

Harvesting Lentiviral Particles (H1)

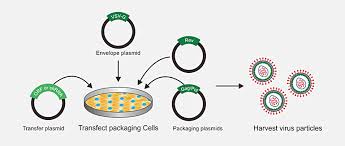

Lentivirus production begins with the harvesting of lentiviral particles from producer cells. This process involves harvesting the supernatant containing lentiviral vectors and purifying them to remove cellular debris.

Transfection Methods (H2)

Transfection methods are critical for introducing lentiviral vector constructs into producer cells. Common techniques include calcium phosphate transfection, lipid-based transfection, and electroporation.

Calcium Phosphate Transfection (H3)

Calcium phosphate transfection utilizes calcium phosphate-DNA precipitates to deliver lentiviral vector constructs into producer cells. This method is cost-effective but requires optimization for efficient lentivirus production.

Lipid-Based Transfection (H3)

Lipid-based transfection employs cationic lipids or liposomes to encapsulate lentiviral vector DNA and facilitate its entry into producer cells. This method offers high transfection efficiency but may be associated with cytotoxicity.

Electroporation (H3)

Electroporation involves applying electrical pulses to create transient pores in cell membranes, allowing lentiviral vector DNA to enter producer cells. This method is highly efficient but requires specialized equipment.

Producer Cell Lines (H2)

Choosing the appropriate producer cell line is crucial for efficient lentivirus production. Common cell lines include HEK293T, HeLa, and COS-7, each offering unique advantages and considerations.

HEK293T Cells (H3)

HEK293T cells are widely used for lentivirus production due to their high transfection efficiency and robust growth characteristics. However, optimizing culture conditions is essential to maximize lentiviral yield.

HeLa Cells (H3)

HeLa cells are another popular choice for lentivirus production, offering high permissiveness to lentiviral infection. Careful monitoring of cell growth and viability is necessary to maintain optimal lentiviral production.

COS-7 Cells (H3)

COS-7 cells, derived from African green monkey kidney tissue, are commonly used for lentivirus production, particularly for applications requiring protein expression. Optimization of culture conditions is essential for consistent lentiviral yield.

Lentivirus Production Optimization (H1)

Optimizing lentivirus production is essential for maximizing yield and transduction efficiency. Several factors influence lentiviral production, including culture conditions, transfection efficiency, and purification methods.

Culture Conditions (H2)

Optimal culture conditions, including medium composition, pH, and temperature, are critical for maintaining producer cell viability and maximizing lentiviral yield.

Transfection Efficiency (H2)

Enhancing transfection efficiency through optimization of transfection reagents, DNA concentration, and cell density can significantly increase lentiviral production.

Purification Methods (H2)

Purification methods, such as ultracentrifugation, size exclusion chromatography, and ultrafiltration, are employed to isolate lentiviral particles from producer cell debris and contaminants.

FAQs (H1)

How long does lentivirus production take? (?)

Lentivirus production typically takes 3-5 days from transfection to harvest, depending on the specific protocol and culture conditions.

What are the key considerations for optimizing lentivirus production? (?)

Key considerations for optimizing lentivirus production include selecting appropriate producer cell lines, optimizing transfection efficiency, and fine-tuning culture conditions.

Can lentivirus production be scaled up for large-scale applications? (?)

Yes, lentivirus production can be scaled up for large-scale applications by optimizing culture conditions, utilizing high-capacity bioreactors, and implementing automated purification techniques.

How can I increase lentiviral yield in my experiments? (?)

To increase lentiviral yield, focus on optimizing transfection efficiency, selecting robust producer cell lines, and maintaining optimal culture conditions throughout the production process.

What are the common challenges associated with lentivirus production? (?)

Common challenges include low transfection efficiency, cell toxicity from transfection reagents, and variability in lentiviral yield due to inconsistent culture conditions.

Are there alternative methods for lentivirus production? (?)

Yes, alternative methods such as adeno-associated virus (AAV) production and retroviral vector production offer alternatives to lentivirus-based gene delivery, each with its advantages and limitations.

Conclusion

In conclusion, lentivirus production is a multifaceted process that requires careful optimization and consideration of various factors to achieve optimal results. By understanding the principles of lentivirus production and implementing best practices, researchers can harness the power of lentiviral vectors for diverse applications in biotechnology and medicine.

No comments yet