Geonets, integral components of geosynthetics, play a critical role in various civil engineering and environmental applications. They are widely used for soil stabilization, erosion control, drainage, and waste containment. Ensuring the longevity and performance of geonets requires proper maintenance and regular inspections. This blog delves into the essential practices for maintaining and inspecting geonets, emphasizing their importance and Geonet new zealand practical guidelines to maximize their lifespan and effectiveness.

Understanding Geonets

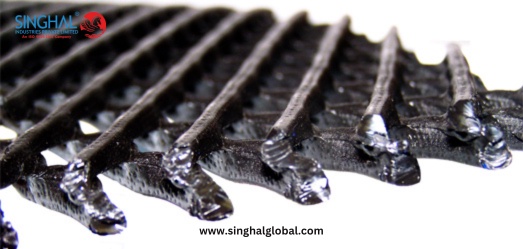

Before discussing maintenance and inspection, it’s important to understand what geonets are and their primary functions. Geonets are synthetic materials made from high-density polyethylene (HDPE) or polypropylene, designed to provide drainage and reinforcement in civil engineering projects. They consist of intersecting ribs that form a net-like structure, allowing for the efficient flow of liquids and gases while maintaining soil stability.

Importance of Maintenance and Inspection

Regular maintenance and inspection of geonets are crucial for several reasons:

- Longevity: Proper care extends the lifespan of geonets, ensuring they continue to function effectively over time.

- Performance: Regular checks help identify and rectify any issues that could compromise the geonet’s performance.

- Safety: Ensuring that geonets are in good condition helps prevent structural failures and environmental hazards.

- Cost-Effectiveness: Early detection of problems can save significant repair costs and prevent expensive project delays.

Maintenance Practices for Geonets

Effective maintenance of geonets involves several key practices, each aimed at preserving their structural integrity and functionality:

1. Regular Cleaning

Over time, geonets can accumulate debris, soil, and other materials that can obstruct their drainage capabilities. Geonet geotextile cleaning helps maintain their efficiency.

- Procedure: Use water jets or air blowers to remove accumulated debris. In some cases, manual cleaning may be necessary for heavily soiled areas.

- Frequency: Schedule cleaning based on the environmental conditions and the specific application. For instance, geonets in landfill drainage systems may require more frequent cleaning compared to those used for soil stabilization.

2. Vegetation Control

In outdoor applications, vegetation growth can interfere with geonet functionality. Roots can penetrate and damage the net structure, while plant matter can block drainage paths.

- Procedure: Implement regular vegetation control measures such as trimming, mowing, or the application of herbicides around the geonet installation.

- Frequency: Conduct vegetation control quarterly or as needed, depending on the rate of plant growth in the area.

3. Repair and Reinforcement

Physical damage to geonets can occur due to heavy loads, construction activities, or natural events like landslides. Prompt repair and reinforcement are essential to maintain their effectiveness.

- Procedure: Inspect for tears, holes, or other damages. Use compatible geonet materials and appropriate sealing techniques to repair any identified damage.

- Frequency: Perform visual inspections monthly and after any significant weather events or construction activities in the vicinity.

4. Environmental Protection

Geonets can degrade due to prolonged exposure to UV radiation and extreme temperatures. Protecting them from these elements is crucial.

- Procedure: Use UV-protective coatings or covers to shield geonets from direct sunlight. In areas with extreme temperatures, consider using geonets made from materials designed to withstand such conditions.

- Frequency: Apply protective measures during the initial installation and check their condition during regular inspections.

Inspection Guidelines for Geonets

Routine inspections are vital for detecting potential issues early and ensuring that geonets perform as intended. Here are comprehensive guidelines for inspecting geonets:

1. Visual Inspection

Regular visual inspections help identify obvious signs of wear and tear, physical damage, or obstruction.

- Procedure: Walk along the geonet installation, looking for visible damage, areas of accumulated debris, or signs of blockage. Use a checklist to ensure a thorough examination.

- Frequency: Conduct visual inspections monthly and after severe weather conditions or heavy usage periods.

2. Functional Testing

Functional testing involves assessing the drainage performance of geonets to ensure they are operating effectively.

- Procedure: Use water flow tests to evaluate the drainage capacity of the geonet. Measure the flow rate at different points to detect any reductions in performance.

- Frequency: Perform functional tests biannually or after any major cleaning or maintenance activities.

3. Structural Integrity Assessment

Assessing the structural integrity of geonets is crucial, especially in load-bearing applications.

- Procedure: Check for any sagging, displacement, or deformation of the geonet structure. Use tools such as probes or cameras for a detailed examination of areas that are difficult to access.

- Frequency: Conduct structural assessments annually and after any events that could impact the geonet’s stability, such as earthquakes or heavy machinery operation.

4. Documentation and Record-Keeping

Maintaining detailed records of inspections and maintenance activities is essential for tracking the geonet’s condition over time and planning future maintenance.

- Procedure: Document the findings of each inspection, noting any issues identified and actions taken. Keep a log of maintenance activities, including cleaning, repairs, and environmental protection measures.

- Frequency: Update records after each inspection and maintenance activity.

Best Practices for Long-Term Performance

To ensure the long-term performance of geonets, consider implementing the following best practices:

1. Use High-Quality Materials

Invest in high-quality geonets that are specifically designed for the environmental conditions of your project. Singhal Industries offers a range of durable and high-performance geonets suitable for various applications.

2. Follow Manufacturer Guidelines

Adhere to the manufacturer’s installation and maintenance guidelines to maximize the effectiveness and lifespan of geonets.

3. Train Personnel

Ensure that all personnel involved in the installation, maintenance, and inspection of geonets are properly trained. This includes understanding the specific requirements of the geonets used and the conditions they will face.

4. Engage Professional Services

For complex projects or when in-house expertise is limited, engage professional services for installation, maintenance, and inspection. Experts can provide specialized knowledge and skills, ensuring that geonets are properly maintained and inspected.

Conclusion

Maintaining and inspecting geonets are critical practices that ensure their longevity and performance in various applications. By implementing regular cleaning, vegetation control, repair, and environmental protection measures, you can significantly enhance the durability of geonets. Routine inspections, including visual checks, functional testing, and structural assessments, help detect issues early and prevent costly failures. Adhering to Geonet india, using high-quality materials, and engaging professional services when necessary further ensure that geonets perform effectively over their intended lifespan.

In Dubai’s demanding climate, these maintenance and inspection strategies are particularly vital. By following these guidelines, you can ensure that your geonet installations continue to provide reliable performance and contribute to the success and safety of your projects.

Frequently Asked Questions (FAQs):

FAQ 1: What maintenance practices does Singhal Industries recommend for ensuring the longevity of geonets?

Answer: Singhal Industries recommends several key maintenance practices to ensure the longevity of geonets:

- Regular Cleaning: Use water jets or air blowers to remove accumulated debris and soil, ensuring the geonet's drainage capabilities remain efficient.

- Vegetation Control: Implement regular measures such as trimming, mowing, or applying herbicides to prevent vegetation growth that can interfere with geonet functionality.

- Repair and Reinforcement: Inspect for physical damage like tears or holes and use compatible materials and sealing techniques for prompt repairs.

- Environmental Protection: Use UV-protective coatings or covers and select materials designed to withstand extreme temperatures to protect geonets from environmental degradation.

FAQ 2: How often should geonets be inspected according to Singhal Industries?

Answer: Singhal Industries advises the following inspection schedule for geonets:

- Visual Inspections: Conduct monthly visual inspections and additional checks after severe weather conditions or heavy usage periods.

- Functional Testing: Perform functional tests biannually to assess drainage performance.

- Structural Integrity Assessment: Conduct annual structural assessments and after events that could impact the geonet’s stability, such as earthquakes or heavy machinery operation.

- Documentation: Update inspection and maintenance records after each activity to track the geonet’s condition and plan future maintenance.

FAQ 3: What best practices does Singhal Industries suggest for long-term performance of geonets?

Answer: Singhal Industries suggests the following best practices for ensuring long-term performance of geonets:

- Use High-Quality Materials: Invest in durable and high-performance geonets designed for the specific environmental conditions of your project.

- Follow Manufacturer Guidelines: Adhere strictly to the manufacturer’s installation and maintenance guidelines to maximize effectiveness and lifespan.

- Train Personnel: Ensure all personnel involved in installation, maintenance, and inspection are properly trained in the specific requirements and conditions the geonets will face.

- Engage Professional Services: For complex projects or when in-house expertise is limited, engage professional services for installation, maintenance, and inspection to leverage specialized knowledge and skills.

No comments yet