Introduction

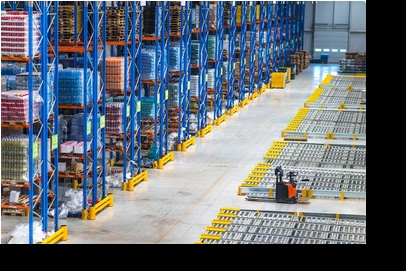

In the ever-evolving world of warehousing and logistics, businesses are constantly seeking innovative storage solutions to optimize space, enhance productivity, and improve inventory management. Push Back Pallet Racking is a dynamic storage system that has gained popularity for its ability to offer high-density storage while maintaining efficient accessibility to multiple pallets. This comprehensive guide delves into the concept of Push Back Pallet Racking, its working principles, benefits, and how it takes warehouse storage to the next level.

Understanding Push Back Pallet Racking

Push Back Pallet Racking is a type of high-density storage system that operates on the Last-In-First-Out (LIFO) principle. Unlike conventional pallet racking systems, which require individual aisles for each row, Push Back Racking utilizes a series of nested carts on inclined rails within each lane. When a new pallet is loaded, it pushes the existing pallets further back along the inclined rails. As a result, the next available pallet is automatically positioned at the front of the lane for easy access during retrieval.

The nested cart design ensures a continuous flow of products, eliminating the need for forklifts to enter the racking system. The carts are equipped with brakes, which ensure safe and controlled movement during loading and unloading processes. The innovative design of Push Back Pallet Racking makes it an excellent choice for businesses dealing with a large number of pallets of the same product.

How Push Back Pallet Racking Works

-

Loading Process: When a forklift operator loads a new pallet onto the lane, they gently push it back, causing the existing pallets to move along the inclined rails.

-

Automatic Nesting: The inclined rails allow the nested carts to slide down gently under the force of gravity, nestling the pallets securely together.

-

Unloading Process: During the unloading process, the forklift operator retrieves the front pallet by pulling it forward, causing the remaining pallets to roll forward automatically.

Advantages of Push Back Pallet Racking

-

High-Density Storage: Push Back Pallet Racking offers higher storage density compared to selective racking systems, making it ideal for businesses with limited warehouse space. By efficiently utilizing available space, warehouses can store a larger number of pallets.

-

Improved Accessibility: Despite its high-density design, Push Back Pallet Racking allows for easy access to multiple pallets within each lane. The ability to store and retrieve multiple pallets without the need to drive into the racking system enhances efficiency and reduces loading and unloading times.

-

FIFO/LIFO Storage Flexibility: Push Back Pallet Racking can be configured to operate on either the First-In-First-Out (FIFO) or Last-In-First-Out (LIFO) principle, depending on the specific storage needs of the business. This flexibility is particularly beneficial for businesses dealing with perishable goods or time-sensitive products.

-

Reduced Aisle Space: Unlike selective racking systems, Push Back Racking requires fewer aisles, freeing up more space for additional storage or operational activities. The reduced need for aisles contributes to cost savings and improved space utilization.

-

Enhanced Safety: The automatic nesting and controlled movement of pallets within the inclined rails minimize the risk of accidents or product damage during loading and unloading. This ensures a safer working environment for warehouse personnel.

Implementing Push Back Pallet Racking

The successful implementation of Push Back Pallet Racking requires careful planning and consideration of the warehouse's specific needs. Here are some key factors to keep in mind:

-

Product Characteristics: Push Back Racking is most suitable for storing multiple pallets of the same product. It is important to ensure that the products have consistent dimensions and weight.

-

Load Capacity: Assess the weight capacity of the racking system and ensure it aligns with the heaviest pallets that will be stored.

-

Rack Configuration: Design the racking system with the appropriate number of lanes and levels to accommodate the required number of pallets.

-

Safety Considerations: Train warehouse personnel on the proper loading and unloading procedures to maintain a safe working environment. Regular inspections and maintenance of the racking system are essential to prevent accidents and ensure optimal performance.

Conclusion

Push Back Pallet Racking represents a significant advancement in warehouse storage solutions. Its high-density design, coupled with efficient accessibility to multiple pallets, sets it apart as a game-changer in the logistics industry. By making the most of available space, improving inventory management, and enhancing safety, Push Back Pallet Racking takes warehouse storage to the next level.

Businesses looking to maximize their storage capacity, optimize operations, and streamline inventory management should consider implementing Push Back Pallet Racking. Its advantages, such as high-density storage, improved accessibility, and storage flexibility, make it an ideal choice for warehouses with a significant volume of identical products. Embracing Push Back Pallet Racking can lead to increased efficiency, reduced costs, and a competitive edge in the fast-paced world of warehousing and logistics.

No comments yet