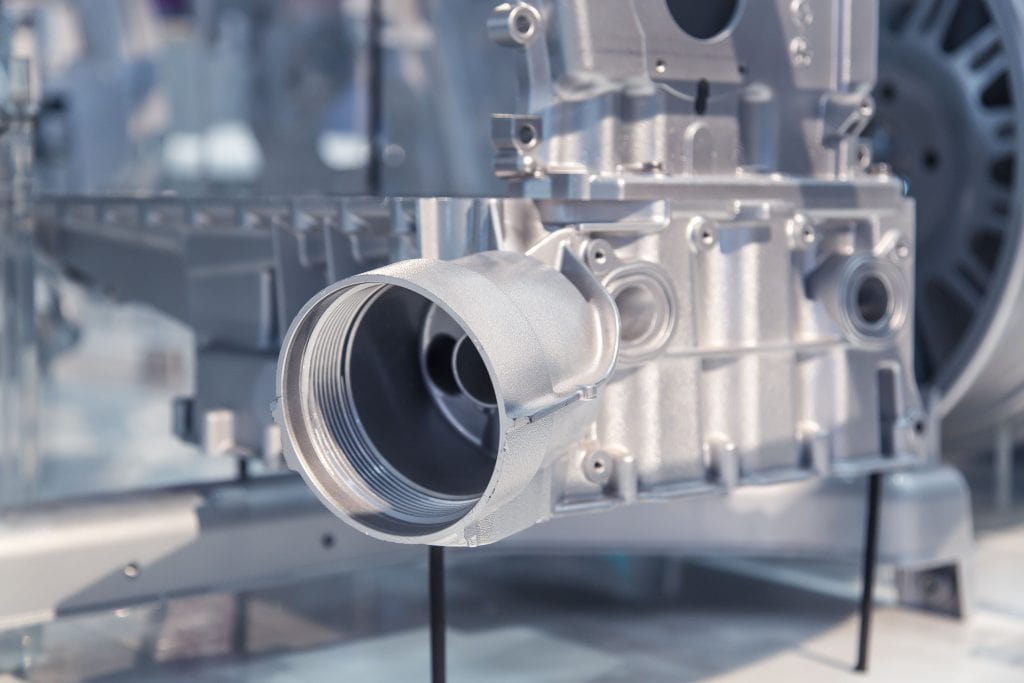

Metal casting

Patternmaking. The most common way of making a metal casting mold with PC helped plan frameworks.

Coremaking. Most casting strategies require the incorporation of a center to make the inside surfaces of the part you are casting.

Molding. Producers can make molds out of numerous materials including sand, mortar, and metal, contingent upon the casting technique.

Liquefying and Pouring. When the maker has made the form, they will empty or infuse liquid metal into it.

Wrapping up. Producers might have to sand or buff the finished piece.

What is a sprinter in casting?

A sprinter is a more modest breadth channel that coordinates the liquid metal is coordinated towards the singular part (especially normal while casting numerous parts immediately). The part where the metal arrives at its objective and starts to stream into the form depression is known as the 'entryway'.

What is hot tear in casting?

Hot tearing is one of metal casting absconds and frequently found in the casting items like breaks on a superficial level. Solidification of metal causes a warm constriction and shrinkage, when the compression and shrinkage happen in the event that a metal compound is controlled by shape plan, it will impact hot tearing. Investment casting manufacturer France

What is shovel in casting?

Shovels are different kinds of casting devices that comprise of a redo sheet metal or steel dish with a wooden handle. They are utilized for moving or moving the molding sand into the holder, molding box, or jar. Shovels are essentially utilized for blending, treating, and molding the foundry sand the hard way

What number of kinds of metal casting are there?

There are two kinds of die casting - cold chamber and cylinder or gooseneck. These techniques shift as per how the liquid metal is infused into the die. Understanding the distinction between the two cycles can help in settling on the creation strategy for the plan of a section.

Material Utilization for casting?

Normal casting metals are aluminum, magnesium, and copper amalgams. Different materials incorporate tin, zinc, and lead amalgams, and iron and steel are additionally casted in graphite molds. Super durable molds, while enduring more than one casting actually have a restricted life prior to breaking down.

What is sprue and riser in casting?

Sprue - Entry from pouring bowl to the form depression. It controls the progression of liquid metal into the form. Riser Supply of liquid metal in the casting so hot metal can stream once more into the form depression when there is a decrease in the volume of metal because of hardening. sand casting manufacturer France

What are the 3 stages in metal casting?

General Strides of Metalcasting

Make the expert example and corebox.

Make the shape and center.

Soften the amalgam.

Empty the liquid metal into the shape.

Permit the metal to harden.

Eliminate the casting from the shape.

Finish the casting.

What is casting and Molding?

Molding is an interaction that includes forming a warmed material around a shape. The material is then permitted to cool and solidify, assuming the state of the shape. Normal materials that are utilized in molding incorporate plastics, glass, and metals. Casting, then again, includes emptying a liquid material into a shape.

What is the distinction between sand casting and metal casting?

The greatest and most clear contrast between the die and sand casting process is the materials used to shape the molds. As we surveyed above, die casting utilizes a metal form, while sand casting utilizes a shape made from sand.

No comments yet