If you work in an industrial setting, you likely know the importance of pipe marking labels. These labels are essential for keeping workers safe and ensuring that everyone knows what is going on with the pipes. In this article, we will take a closer look at pipe marking labels, including what they are, why they are important, and how you can implement them in your facility.

What Are Pipe Marking Labels?

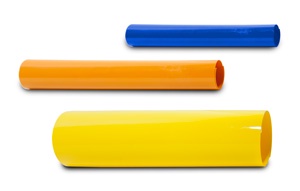

Pipe marking labels are tags that are affixed to pipes to indicate their contents, direction of flow, and other important information. These labels come in a variety of shapes, sizes, and colors, and they are used to communicate vital information about the pipes to workers and emergency responders.

Why Are Pipe Marking Labels Important?

There are several reasons why pipe marking labels are important. First and foremost, they help workers identify the contents of the pipes they are working with. This is essential for preventing accidents and ensuring that workers handle the pipes correctly.

In addition, pipe marking labels help emergency responders quickly identify the contents of pipes in the event of an accident or other emergency. This information is critical for determining the appropriate response and minimizing the risk of injury or damage.

Finally, pipe marking labels are required by law in many industries. For example, the Occupational Safety and Health Administration (OSHA) requires pipe marking labels in certain settings to ensure worker safety.

How Are Pipe Marking Labels Implemented?

Implementing pipe marking labels is a relatively straightforward process. The first step is to determine which pipes need to be labeled and what information needs to be included on the labels. This will depend on the contents of the pipes and the specific requirements of your industry.

Once you have this information, you can select the appropriate labels and install them on the pipes. It is important to ensure that the labels are affixed securely and are clearly visible to workers and emergency responders.

Best Practices for Pipe Marking Labels

There are several best practices that you should follow when implementing pipe marking labels. These include:

- Use standardized colors and labels - Standardized colors and labels make it easier for workers and emergency responders to quickly identify the contents of the pipes.

- Use clear and concise language - Pipe marking labels should use clear and concise language to ensure that everyone understands what is going on with the pipes.

- Affix labels in a consistent location - Labels should be affixed in a consistent location on each pipe to ensure that they are easy to find and read.

- Update labels as necessary - Labels should be updated as necessary to reflect changes in the contents of the pipes or other important information.

Conclusion

Pipe marking labels are an essential component of industrial safety. They help workers identify the contents of pipes, allow emergency responders to quickly respond to accidents, and are often required by law. By following best practices for pipe marking labels, you can ensure that your facility is safe and compliant with industry standards.

No comments yet