Precision manufacturing is a cornerstone of industrial progress, and at the heart of this precision lies the fascinating world of Tool and Die Making. In this journey, we'll delve into the rich history, explore the role of precision, discuss the materials, components, and technologies involved, and highlight the importance of this craft in New Zealand's industrial landscape.

Historical Overview

The roots of Tool and Die Making trace back to the Industrial Revolution when the demand for standardized components soared. Craftsmen began crafting specialized tools and dies to meet the growing needs of mass production, laying the foundation for modern manufacturing.

The Role of Precision

Precision is not merely a buzzword in Tool and Die Making ; it is the essence of the craft. Every cut, every contour must be meticulously calculated to ensure the perfection of the final product. Precision is the silent hero that guarantees the seamless operation of machinery and the quality of manufactured items.

Materials Used in Tool and Die Making

Common metals like steel and aluminum are the backbone of tool and die production. However, as industries evolve, so do material requirements. Advanced alloys and composites cater to specialized needs, pushing the boundaries of what's possible.

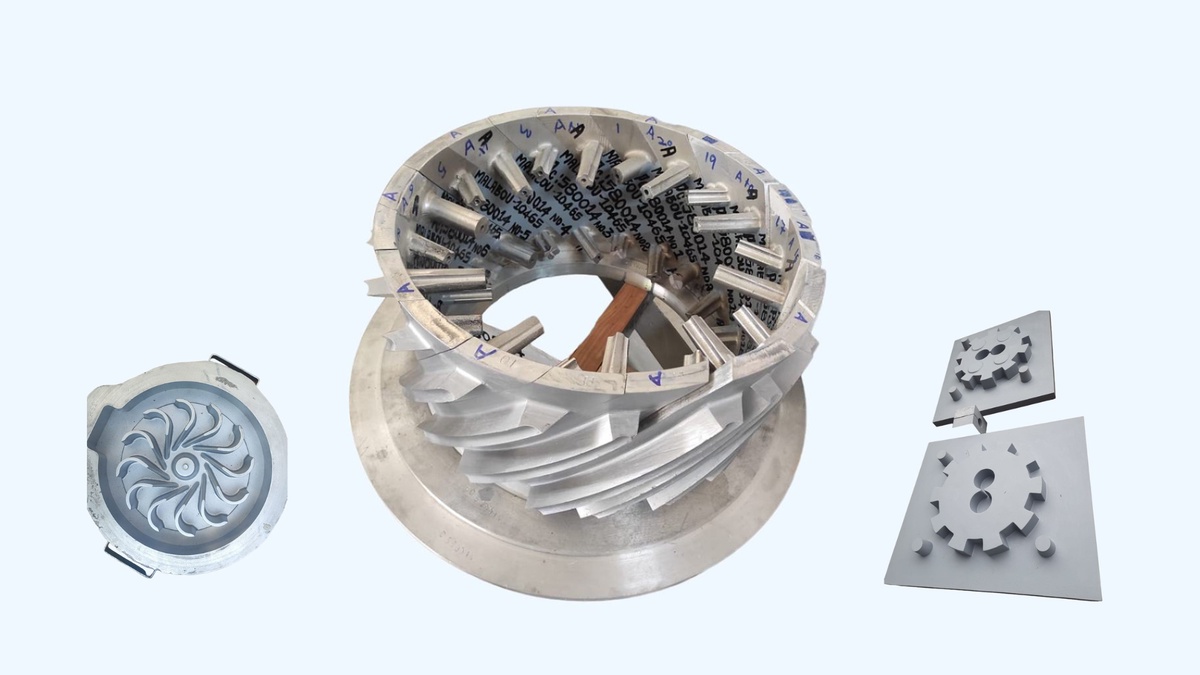

Key Components of Tool and Die Sets

A tool and die set is a symphony of components working in harmony. From punches and dies to plates and retainers, each piece has a specific role. Understanding the functions and interdependencies is crucial for crafting effective tool and die sets.

Modern Technologies in Tool and Die Making

In the 21st century, Tool and Die Making embraces cutting edge technologies. Computer Numerical Control (CNC) machining, 3D printing, and automation have revolutionized the precision manufacturing landscape, enhancing efficiency and reducing production times.

Training and Skills in the Industry

Becoming a proficient tool and die maker requires a combination of theoretical knowledge and practical skills. Educational paths range from vocational training to advanced degree programs, emphasizing the importance of hands-on experience in this field.

Challenges in Tool and Die Making

The industry faces challenges stemming from evolving market trends and technological advancements. Staying ahead requires adaptability and a proactive approach to incorporating new methodologies.

Sustainability in Tool and Die Manufacturing

As industries worldwide shift towards sustainable practices, Tool and Die Making is no exception. Green initiatives, recycling, and waste reduction strategies are becoming integral to the manufacturing process.

Quality Control Measures

Maintaining high standards is non negotiable in precision manufacturing. Inspection techniques, adherence to standards, and certifications ensure that every tool and die set meets the stringent quality requirements.

Innovations in the Field

Recent breakthroughs, such as the integration of artificial intelligence and smart manufacturing, showcase the dynamic nature of the industry. The future promises even more innovations, shaping the landscape of Tool and Die Making.

Tool and Die Making in New Zealand

In the picturesque landscapes of New Zealand, the tool and die making industry has carved its niche. Boasting a robust manufacturing sector, New Zealand has witnessed significant growth, with tool and die making playing a pivotal role in supporting various industries.

Case Studies

Examining real world applications highlights the impact of tool and die making on industries. From automotive components to aerospace parts, success stories underscore the importance of precision in manufacturing.

The Future Landscape

As technology continues to advance, the future of Tool and Die Making in NZ holds exciting possibilities. Emerging technologies and global trends will shape the industry, making it an ever evolving and dynamic field.

Conclusion

In conclusion, Tool and Die Making in NZ is the unsung hero of precision manufacturing . From its historical roots to the modern day applications in New Zealand and beyond, this craft plays a crucial role in shaping the world around us. As we step into the future, the journey into the world of Tool and Die Making promises continued innovation and excellence.

No comments yet