Mechanical Power Press commonly store energy in a pivoting flywheel, which is driven by an electric engine. The flywheel is locked in and separated to a mechanical drive, for example, a driving rod, flighty shaft, erratic stuff or knuckle switches, which convert flywheel revolution to vertical movement. The stroke is of set speed, length, and term. Mechanical presses consequently foster predictable forging results, offer high productivity and exactness, and don't need as high a level of administrator expertise as do different kinds of forging machines. In impression die casting forging, the workpiece is typically struck once in every impression. Mechanical presses are not appropriate for open casting forging, where the length of stroke should fluctuate between strokes.

Power is greatest

The applied power is greatest at the lower part of the work stroke, and the assessed load at a position simply over this point is the reason for the press rating limit. A couple of exceptional plan huge limit presses with evaluations as much as 16,000 tons are in activity.

Late advancements in mechanical presses are zeroing in on expanded firmness of the press design to further develop forging precision, computerization, and high velocity (as far as kick the bucket to-workpiece contact time). They are progressively supplanting hammers in view of more prominent ecological similarity, simplicity of robotization, and lower working expenses.

Screw presses

Screw presses not as generally utilized in that frame of mind as mechanical presses. However, extraordinary screw press attributes are driving an expansion in their utilization. As the name recommends, this kind of press utilizes a mechanical screw to make an interpretation of rotational movement into vertical. Momentarily, the slam goes about as the nut on a turning screw shaft going up or down relying upon screw revolution. Energy is either conveyed from a flywheel, which is normally combined with a force restricting (slipping) grasp, or by an immediate drive switching electric engine. The fundamental benefit of screw presses over offset or wrench type mechanical presses is in the last thickness control when the bites the dust influence one another.

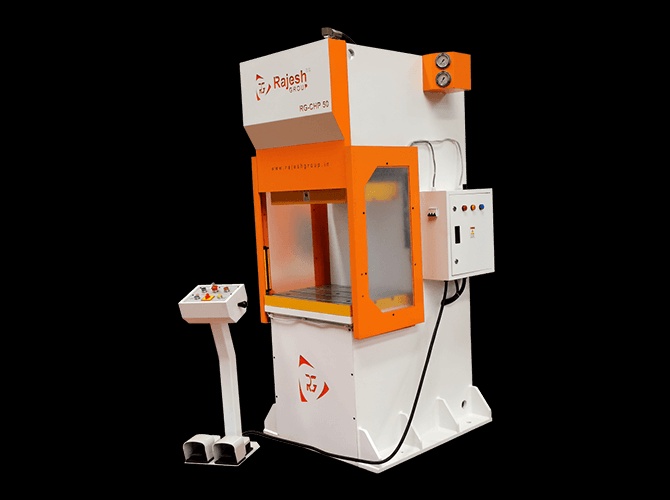

Hydraulic Presses

Hydraulic Presses are worked by huge cylinders driven by high-pressure hydraulic or hydro-pneumatic frameworks. They are sluggish contrasted and mechanical and screw presses and crush instead of effect the workpiece. In activity, hydraulic tension is applied to the highest point of the cylinder, moving the smash descending. At the point when the stroke is finished, pressure applied to the contrary side of the cylinder to raise the slam.

Circuits

Rates and tensions can be firmly controlled. In many presses, circuits accommodate a pay control or successive control, for example quick development, trailed by arrangements with at least two squeezing speeds. The press can likewise be managed to stay at the lower part of the stroke for a foreordained time frame, raised at a sluggish delivery speed, and advanced until it arrives at unique position. At the point when required, hydraulic press speed can be expanded extensively. As a rule, hydraulic presses utilized for open and some shut die casting forging presses use microchips or PCs to control the press activity, for boundaries, for example, slam velocities and positions.

No comments yet