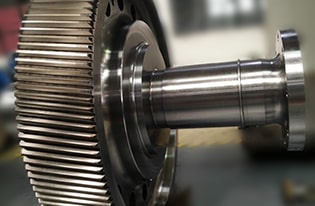

Gears play a pivotal role in transmitting power and ensuring smooth motion in the engineering and machinery industry. To achieve optimal performance and longevity, engineers employ meticulous techniques to refine gear design and improve load mesh capabilities. Two critical factors that profoundly influence gear performance are profile and helix correction. This article delves into the significance of profile and helix correction in gears for load mesh optimization, shedding light on the methods employed by skilled engineers to achieve superior gear performance.

Understanding Gear Profile and Helix Correction

The fundamental essence of gears lies in the interaction of teeth, which mesh to transmit motion. Profile correction primarily focuses on the gear tooth's shape and how well it matches the ideal involute profile. Helix correction, on the other hand, pertains to the angle at which the gear teeth are cut concerning the gear's axis. Both corrections are essential for ensuring smooth and efficient gear operation.

Challenges in Gear Design

Gears are subjected to immense stress and wear during operation. The challenges in gear design arise from imperfections in the manufacturing process, such as material variations, tool wear, and dimensional errors. Additionally, loading conditions can lead to misalignments and deflections, resulting in decreased mesh quality and accelerated wear. Gearbox brands in India ensure that the correction is safe and secured for the right alignment.

Benefits of Profile and Helix Lead Correction

- Enhanced Load Distribution – Correcting gear profiles ensures a more uniform distribution of the load across the teeth profile and avoids tip-root interference. This prevents localized stress concentrations, reducing the likelihood of premature gear failure.

- Improved Efficiency – Helix lead correction enables gears to operate under uniform distribution of load along with the helix resulting in smoother meshing and avoids over loading. This leads to improved overall gear efficiency.

- Noise Reduction – Accurate profile and helix corrections minimize gear vibrations and noise, leading to quieter and more reliable gear operation.

- Extended Gear Life – By mitigating stress concentrations and reducing wear, profile and helix correction significantly contribute to increasing the gear's operational lifespan.

Methods of Profile and Helix Correction

- Tooth Profile Modifications – Skilled engineers often employ techniques like tip relief, root relief based on tooth bending to achieve profile correction. Tip relief involves slight modification of the gear tooth's tip to avoid interference with mating gear root during meshing.

- Tooth Helix Modifications – Based on tooth deflection on account of bending and torsion on load, helix lead correction is done. Lead modifications are employed to correct the helix angle, achieving smoother meshing and load distribution. Crowning is also used to accommodate misalignment ensuring uniform contact along the tooth width.

- Computer-Aided Design and Simulation – Modern engineering relies heavily on computer-aided design (CAD) and simulation tools. Engineers use advanced software to analyze gear meshes under various load conditions, identifying areas that require correction. Virtual simulations help optimize the gear design and provide insights into potential performance improvements.

- Precision Manufacturing Techniques – To realize the desired gear corrections, precision manufacturing processes are essential. Advanced machining and grinding technologies ensure the accurate implementation of profile and helix corrections during gear production.

Case Studies – Success Stories of Load Mesh Optimization

- Aerospace Industry – In the aerospace sector, where reliability and safety are paramount, engineers have utilized profile and helix correction to improve gear performance in aircraft engines. These corrections have resulted in reduced noise levels, improved fuel efficiency, and increased service life.

- Automotive Sector – In the automotive industry, load mesh optimization has been instrumental in enhancing the performance of gearboxes. By incorporating profile and helix corrections, engineers have achieved smoother gear shifts, reduced power loss, and prolonged gearbox durability.

Conclusion

Profile and helix correction in gears are crucial aspects that significantly impact load mesh optimization. The benefits of these corrections extend beyond improved performance and efficiency, encompassing noise reduction and extended gear life including planetary gears which are largely used in the crammed-up spaces for reduction of speed and torque. High speed gearbox manufacturers in India, hence, ensure the alignment of the gears.

Engineers' innovative approaches, supported by advanced design tools and precision manufacturing techniques, continue to push the boundaries of gear technology, making machinery more reliable and efficient across various industries.

No comments yet