Introduction

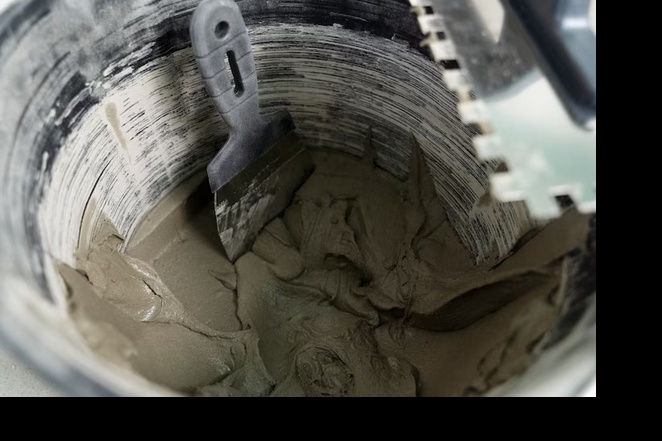

In the world of construction, one of the fundamental elements is concrete. Ready mix concrete, in particular, has gained immense popularity due to its convenience and quality. However, understanding the factors that influence ready mix concrete price is essential for construction professionals and project planners. This comprehensive guide explores everything you need to know about ready mix concrete prices, from the factors affecting them to the benefits of making informed pricing decisions.

Factors Influencing Ready Mix Concrete Prices

The price of ready mix concrete is not fixed and can vary widely depending on several key factors. Understanding these factors is crucial for estimating costs accurately.

-

Location: The geographic location of the construction site plays a significant role in pricing. Transporting ready mix concrete over long distances can increase costs due to fuel expenses and delivery time.

-

Volume: The volume of concrete needed for a project is a primary determinant of price. Larger quantities typically result in lower unit prices since batching and delivery costs can be spread over a larger volume.

-

Mix Design: The specific mix design required for a project affects the price. Customized mixes with special additives, aggregates, or admixtures may be more expensive than standard mixes.

-

Project Complexity: The complexity of the construction project, including design requirements and site conditions, can impact the cost of ready mix concrete. Projects with unique challenges may require more specialized concrete mixes, leading to higher prices.

-

Seasonal Variations: Seasonal factors can influence ready mix concrete prices. Prices may be higher during peak construction seasons when demand is high and supply is limited.

-

Distance to the Batching Plant: The proximity of the construction site to the batching plant where the concrete is produced affects transportation costs. Longer distances can result in higher prices.

-

Order Size: Larger orders often lead to better pricing due to economies of scale. Contractors who place frequent and substantial orders may negotiate favorable rates.

-

Supplier Pricing Policies: Different ready mix concrete suppliers have varying pricing policies. Some may offer discounts for early payment or long-term contracts, while others may have fixed pricing structures.

Types of Ready Mix Concrete

Before delving deeper into pricing considerations, it's essential to understand the various types of ready mix concrete available, as they can significantly impact the cost.

-

Standard Ready Mix Concrete: This is the most common type of ready mix concrete, suitable for general construction purposes. It consists of cement, aggregates, water, and sometimes additives to enhance workability or strength.

-

High-Strength Concrete: High-strength ready mix concrete is formulated to have superior compressive strength, making it ideal for structural applications where strength is paramount.

-

Fiber-Reinforced Concrete: This type of concrete incorporates fibers (such as steel or synthetic) to enhance its durability and reduce cracking. Fiber-reinforced concrete can be more expensive due to the added material cost.

-

Colored Concrete: Colored ready mix concrete allows for customization of the concrete's appearance. Pigments or dyes are added to achieve the desired color, making it suitable for decorative applications.

-

Pervious Concrete: Pervious or permeable concrete is designed to allow water to pass through it, making it an eco-friendly choice for applications like driveways and parking lots. Its pricing may differ due to its unique composition.

Calculating Ready Mix Concrete Prices

To calculate the cost of ready mix concrete for a specific project, it's important to consider the following steps:

-

Determine the Volume: Measure or estimate the volume of concrete needed for your project in cubic yards or cubic meters. You can use online calculators or consult with a concrete supplier for assistance.

-

Select the Mix Design: Choose the appropriate mix design based on the project's requirements. Discuss this with the supplier to ensure you get the right mix.

-

Get Multiple Quotes: Reach out to multiple ready mix concrete suppliers in your area to obtain quotes. Be clear about the volume, mix design, and any additional requirements.

-

Consider Delivery Charges: Include delivery charges in your cost calculations. The distance from the batching plant to your construction site can affect these charges.

-

Factor in Additional Costs: Don't forget to account for any additional costs, such as pump rental if needed, labor for concrete placement, and any special admixtures or additives.

-

Compare Quotes: Compare the quotes you receive from different suppliers, considering not only the price but also factors like reputation, reliability, and service quality.

-

Negotiate: If you have a large project or plan to work with a supplier long-term, consider negotiating for better pricing or favorable terms.

Benefits of Understanding Ready Mix Concrete Prices

Understanding ready mix concrete prices is advantageous for both construction professionals and project planners. Here are the key benefits:

-

Accurate Budgeting: Having a clear understanding of concrete pricing allows for accurate budgeting, helping to prevent cost overruns during the construction phase.

-

Cost Control: Knowledge of pricing factors empowers project managers to make cost-effective decisions, such as optimizing order sizes and delivery schedules.

-

Contract Negotiation: Armed with pricing information, contractors can negotiate favorable terms with ready mix concrete suppliers, potentially reducing overall project costs.

-

Resource Allocation: By accurately estimating concrete costs, project planners can allocate resources more efficiently and ensure that funds are available when needed.

-

Project Viability: Understanding concrete prices early in the project planning phase helps assess the feasibility and viability of construction projects.

-

Project Profitability: For construction companies, pricing knowledge contributes to better profitability, as informed decisions can lead to competitive bidding and higher margins.

Conclusion

Ready mix concrete prices are influenced by numerous factors, including location, volume, mix design, project complexity, and seasonal variations. It's essential for construction professionals and project planners to have a thorough understanding of these factors to accurately estimate concrete costs. By doing so, they can make informed decisions, maintain cost control, negotiate favorable terms, and ultimately contribute to the success and profitability of construction projects. In a dynamic construction industry like Wolverhampton's, where efficiency and cost-effectiveness are paramount, having a comprehensive grasp of ready mix concrete prices is a valuable asset.

No comments yet