In today's competitive manufacturing landscape, businesses are constantly seeking ways to reduce costs and improve the quality of their products. One technology that has proven to be a game-changer in achieving these goals is CNC (Computer Numerical Control) machining. CNC machining services offer a wide range of advantages that not only streamline production processes but also enhance the overall product quality. In this article, we will explore these advantages in detail.

Precision and Accuracy

One of the primary advantages of CNC machining services is the unparalleled precision and accuracy they offer. CNC machines are programmed to follow exact specifications and can produce parts with tolerances as tight as a few micrometers. This level of precision is nearly impossible to achieve consistently with manual online CNC machining services processes. As a result, businesses can reduce the margin of error and ensure that every component produced meets the required specifications.

Cost Reduction through Automation

Automation is a key element of CNC machining services. Once a CNC machine is programmed, it can operate continuously without the need for constant supervision. This reduces the labor costs associated with manual machining, where skilled operators are required to handle every step of the process. With CNC machining, fewer operators are needed, and the machines can run overnight or during weekends, maximizing production efficiency.

Increased Production Speed

CNC machines are known for their high-speed operation. They can perform cutting, milling, drilling, and other machining operations much faster than human operators. This increased production speed translates into shorter lead times and quicker turnaround for customers. Manufacturers can meet tight deadlines and respond to market demands more effectively, giving them a competitive edge.

Consistency in Quality

Maintaining consistent product quality is crucial for any manufacturing business. With CNC machining services, the likelihood of human errors is significantly reduced. Once a program is set up, the machine will replicate the same process for every part, ensuring uniformity in the final product. This consistency is particularly important in industries such as aerospace, automotive, and medical, where even slight variations can lead to catastrophic consequences.

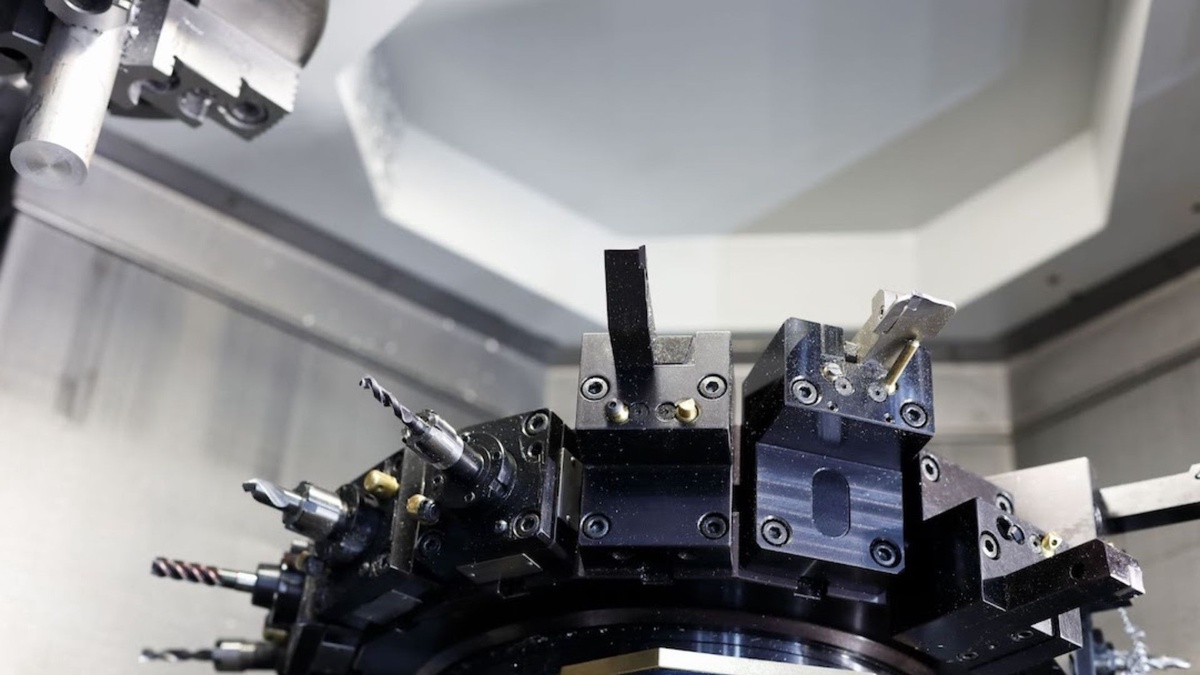

Complex Geometries Made Easy

CNC machining services excel at creating complex and intricate geometries that would be extremely challenging or impossible to achieve manually. These machines can produce 3D shapes, contours, and patterns with ease. As a result, businesses can explore innovative designs and produce parts that were previously considered unattainable. This capability opens up new possibilities for product development and differentiation in the market.

Material Versatility

CNC machining services are compatible with a wide range of materials, including metals, plastics, ceramics, and composites. This versatility allows manufacturers to choose the best material for their specific application, whether it's for strength, durability, conductivity, or other properties. CNC machines can handle exotic materials that are difficult to work with manually, expanding the horizons of what can be produced.

Cost-Effective Prototyping

Prototyping is an essential step in product development, and CNC machining services offer a cost-effective way to create prototypes quickly. Since CNC machines can switch between different jobs with minimal setup time, businesses can produce prototypes without incurring significant tooling costs. This flexibility enables companies to iterate and refine their designs efficiently, reducing the time-to-market for new products.

Reduced Scrap and Waste

Precision and accuracy in CNC machining translate into reduced scrap and waste materials. Unlike manual machining, where errors can lead to the scrapping of entire parts, CNC machines minimize material wastage. This not only contributes to cost savings but also aligns with sustainability goals by reducing the environmental impact of manufacturing operations.

Ease of Maintenance

CNC machines are designed for longevity and ease of maintenance. Regular maintenance routines, such as lubrication and calibration, help keep the machines in optimal condition. Additionally, since CNC machines are operated by software, troubleshooting and diagnosing issues is more straightforward than with traditional manual machines. This ease of maintenance minimizes downtime and ensures continuous production.

Scalability and Adaptability

Whether a business needs to increase production volumes or adapt to changing market demands, CNC machining services offer scalability and adaptability. Adding more CNC machines to a production line is relatively straightforward, allowing businesses to ramp up production as needed. Moreover, since CNC machines are programmable, changes in product specifications or design updates can be implemented quickly, ensuring flexibility in manufacturing.

Conclusion

In a world where manufacturing efficiency and product quality are paramount, CNC machining services stand out as a versatile and indispensable technology. They offer precision, automation, speed, and cost-effective solutions for a wide range of industries. With the ability to produce complex geometries, work with various materials, and minimize waste, CNC machining services are at the forefront of modern manufacturing. By embracing these advantages, businesses can reduce costs, improve quality, and stay competitive in today's dynamic marketplace.

No comments yet