Resistance welding is a widely used joining process in manufacturing, known for its efficiency, reliability, and versatility. Taylor-Winfield Technologies (TWT) stands at the forefront of resistance welding machine manufacturers, offering a range of standard and custom-engineered welders. In this article, we delve into the aspects of resistance welding machines, their applications, and the advantages they bring to various industries.

1. Types of Resistance Welding Machines

a. Spot Welders

Spot welders are commonly used for joining two metal sheets at discrete points. They create strong, localized welds by passing an electric current through the workpieces, causing them to fuse together. Taylor-Winfield’s spot welders come in both press and rocker arm styles, equipped with AC or MFDC controls and power supplies. These machines find applications in automotive, aerospace, and appliance manufacturing.

b. Projection Welders

Projection welders are ideal for joining complex shapes or dissimilar materials. They use specially designed electrodes to concentrate the welding current at specific points, resulting in robust welds. Taylor-Winfield’s projection welders cater to various industries, including automotive, construction, and electrical components.

c. Seam Welders

Seam welders create continuous welds along the length of overlapping metal sheets. They are commonly used for manufacturing pipes, tubes, and containers. Taylor-Winfield offers both standard and custom-engineered seam welders, ensuring precise and consistent welds.

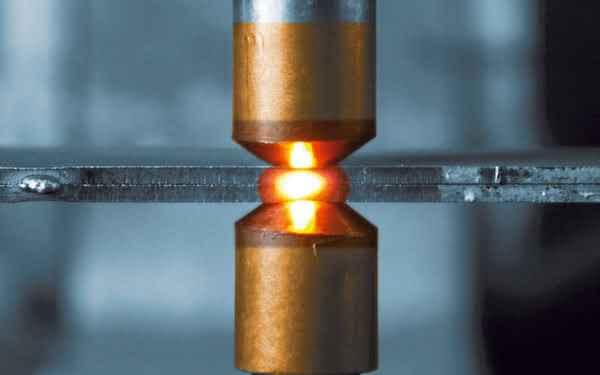

d. Flash Welders

Flash welding is a high-speed process that produces strong, clean welds. Taylor-Winfield’s flash welders are used in applications such as rail manufacturing, wire joining, and pipe welding.

e. Multi-Gun Welders

Multi-gun welders allow simultaneous welding at multiple points. They enhance productivity and are suitable for high-volume production lines. Taylor-Winfield’s multi-gun welders are customizable to meet specific production requirements.

2. Advantages of Taylor-Winfield’s Resistance Welders

a. Robust Construction

Taylor-Winfield’s signature series welders are built to withstand the rigors of industrial production. Their heavy-duty design ensures longevity and reliability.

b. Customization Options

TWT’s welders can be tailored to your unique application. Customization options include throat length, transformer size, control options (AC, DC, MFDC, or CD), weld force, platen size, and more. Whether you need manual or automated operation, TWT can design the right solution for you.

c. Integration with Automation

Taylor-Winfield seamlessly integrates its welders into automated production systems. Examples include robot-assisted fuel tank projection welding, wire solidification, and electrical component welding for electric vehicles (EVs).

d. Technical Support

When you choose Taylor-Winfield, you gain access to technical advice, competent service, and ongoing support throughout the life cycle of your machine. With over 135 years of experience, TWT ensures your welding processes run smoothly.

3. Applications of Resistance Welding Machines

a. Automotive Industry

Resistance welders play a crucial role in assembling car bodies, exhaust systems, and battery packs. They ensure structural integrity and reduce production time.

b. Appliance Manufacturing

From refrigerator components to washing machine drums, resistance welding machines create durable joints in household appliances.

c. Aerospace and Defense

Precision welding is essential in aircraft assembly, missile components, and defense equipment. Taylor-Winfield’s welders meet stringent quality standards.

d. Electrical Components

Resistance welding machines join electrical contacts, connectors, and bus bars. Their speed and accuracy contribute to efficient production.

Conclusion

Taylor-Winfield Technologies continues to innovate and provide cutting-edge resistance welding solutions. Their commitment to quality, customization, and technical support makes them a trusted partner for manufacturers worldwide. Whether you’re building cars, appliances, or aircraft, Taylor-Winfield’s welders ensure strong, reliable connections. Remember, in the world of manufacturing, precision matters, and Taylor-Winfield delivers.

No comments yet