Introduction:

Innovation is the cornerstone of progress in the manufacturing industry, and laser welding services stand at the forefront of technological advancement. From automotive to aerospace, medical to electronics, the transformative impact of laser welding is undeniable. This blog delves into the precision, efficiency, and versatility of laser welding, showcasing its ability to revolutionize manufacturing processes across diverse sectors. Join us as we explore the intricate world of laser welding and its profound implications for the future of manufacturing.

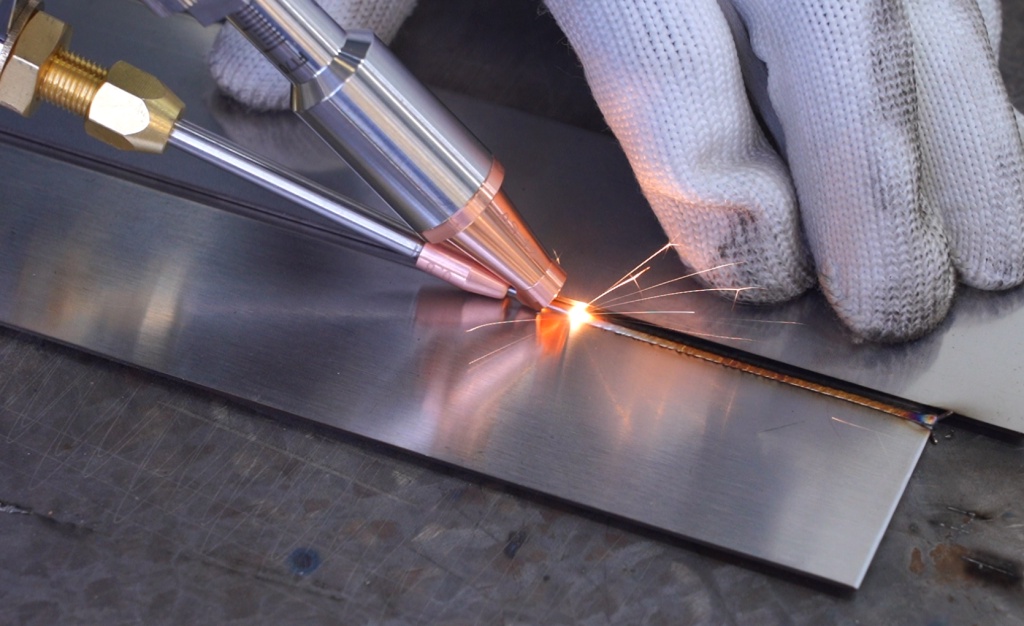

Understanding Laser Welding:

Laser welding harnesses the power of a focused beam of light to seamlessly fuse materials, presenting a level of precision that surpasses conventional welding methods. In this segment, we delve into the fundamental principles of laser welding, unravelling its intricacies and highlighting its distinctive benefits over traditional techniques. From its ability to weld dissimilar materials with ease to its capacity for intricate detail, laser welding revolutionizes the fabrication process. Join us as we explore the inner workings of laser welding and discover how this cutting-edge technology is reshaping the landscape of manufacturing.

Applications in Automotive and Aerospace:

In the dynamic realms of automotive and aerospace, where lightweight materials and intricate assemblies reign supreme, laser welding emerges as an indispensable tool. This subsection delves into the pivotal role of laser welding, illuminating how it elevates production processes, enhances product quality, and fuels innovation in these vital sectors. From seamlessly joining complex components to ensuring structural integrity, laser welding empowers manufacturers to meet the rigorous demands of automotive and aerospace engineering. Join us as we uncover the myriad ways in which laser welding is reshaping the future of mobility and aerospace exploration.

Cost Savings and Efficiency:

In today's competitive manufacturing landscape, cost savings and efficiency are paramount. Laser welding services play a pivotal role in achieving these goals by delivering significant cost savings through reduced material consumption, minimized rework, and enhanced throughput. This segment meticulously explores the economic benefits of laser welding, showcasing how they streamline production processes and optimize resource utilization. From reducing scrap and waste to maximizing productivity, laser welding services offer a cost-effective solution for manufacturers seeking to remain competitive in a rapidly evolving market. Join us as we delve into the transformative impact of laser welding support on the bottom line and overall operational efficiency.

Medical Device Manufacturing:

In the highly regulated field of medical device manufacturing, precision and reliability are non-negotiable. Laser welding assistance plays a pivotal role in this sector, facilitating the production of surgical instruments and implantable devices with unparalleled accuracy. This section meticulously explores how laser welding support meets stringent quality standards, ensuring the integrity and functionality of critical medical components. From seamlessly joining biocompatible materials to creating intricate structures, laser welding assistance provides the precision and consistency required for medical advancements. Join us as we delve into the vital role of laser welding support in advancing healthcare technologies and improving patient outcomes.

Electronics Manufacturing:

In the dynamic realm of electronics manufacturing, laser welding services emerge as a cornerstone of precision and control. By offering the exactitude required to create robust connections without jeopardizing sensitive components, laser welding support ensures the integrity of electronic devices. This subsection delves into the pivotal role of laser welding assistance in the production of consumer electronics and high-tech devices. From seamlessly bonding intricate circuitry to safeguarding delicate components, laser welding assistance upholds the quality standards essential in electronics manufacturing. Join us as we explore how laser welding support contributes to the reliability and performance of electronic products, driving innovation and meeting the demands of a rapidly evolving industry.

Emerging Applications:

As technology advances, laser welding services continue to spearhead innovation in burgeoning fields like additive manufacturing and microfabrication. This segment elucidates how laser welding support is revolutionizing these domains by facilitating precise 3D printing and microcomponent fabrication. By harnessing the power of laser energy, manufacturers can create intricate designs and structures with unparalleled accuracy and efficiency. Laser welding support enables the seamless fusion of materials at a microscopic level, unlocking new possibilities for design and engineering. Join us as we delve into the transformative impact of laser welding support on additive manufacturing and microfabrication, and how they are reshaping the future of manufacturing processes.

Conclusion:

In conclusion, laser welding services epitomize a paradigm shift in manufacturing, embodying unparalleled precision, efficiency, and versatility across diverse industries. As manufacturers navigate the ever-evolving landscape of competitiveness and innovation, laser welding support stands as a cornerstone technology shaping the future of manufacturing processes. With its ability to seamlessly fuse materials, reduce costs, and enhance productivity, Laser welding assistance is poised to remain indispensable in driving forward the realms of automotive, aerospace, electronics, medical devices, and beyond. Join us in embracing the transformative potential of laser welding assistance as we embark on a journey toward greater efficiency, quality, and ingenuity in manufacturing.

No comments yet