Building a safety-conscious mindset is crucial in any environment. By proactively identifying and addressing potential hazards, we can prevent accidents and ensure everyone's well-being. Here's a basic introduction:

- What is a hazard? A hazard is anything that has the potential to cause harm, like a sharp object, a chemical spill, or a slippery floor.

- Why are safety considerations important? Safety measures minimize the risk of injury, illness, and property damage. They also foster a positive work culture and ensure regulatory compliance.

Taking control:

- Hazard identification: Actively look for potential dangers in your workspace.

- Risk assessment: Evaluate the likelihood and severity of harm associated with each hazard.

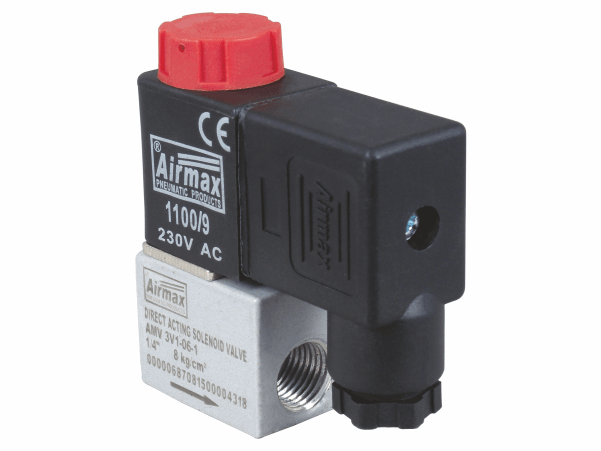

- Control measures: Implement safeguards to minimize risk. This could involve using personal protective equipment (PPE), following safe work procedures, or installing safety devices on machinery like the Best Quality Single Coil Solenoid Valve in India.

By understanding hazards and taking steps to control them, we can create a safer environment for everyone.

Proper Installation Procedures to Ensure Safe Operation

Every piece of equipment has a unique installation process. Before starting, thoroughly read the manufacturer's instructions for your specific model. Following these detailed steps is crucial for proper function and safety.

- Prioritize Safety: Wear appropriate personal protective equipment (PPE) based on the equipment and installation environment. This may include gloves, safety glasses, respirators, or ear protection.

- Prepare the Installation Area: Ensure the designated space meets the equipment's requirements. This includes considering weight capacity, ventilation needs, and compatibility with existing utilities.

- Verify Compatibility: Double-check that the power source (voltage and current) matches the equipment's specifications. Improper power can lead to damage or safety hazards.

- Test and Inspect: Once installed, perform a thorough inspection to ensure all connections are secure and free of leaks or damage. Finally, conduct a test run to verify proper operation according to the manufacturer's instructions.

By following these steps, you can ensure a safe and successful installation for your equipment. For peak performance and longevity, consider using the Best Quality Single Coil Solenoid Valve in India.

Electrical Safety Precautions for Handling Single Coil Solenoid Valves

Single coil solenoid valves are workhorses in automation, but electrical safety is crucial. Here's how to handle them with confidence:

- Lockout/Tagout: Before any work, isolate the valve's power source using a lockout/tagout procedure.

- Double Check Voltage: Ensure the applied voltage matches the solenoid's rating. Mismatches can damage the valve or cause electrical hazards.

- Wiring Woes: Inspect wiring for damage or corrosion. Loose or faulty connections can lead to overheating and potential fire risks.

- Ground Control: Verify proper grounding to prevent electrical leakage and potential shock hazards.

- Moisture Matters: Keep the solenoid dry. Moisture exposure can lead to electrical shorts and malfunction.

By following these precautions, you'll ensure safe operation of your single coil solenoid valve. Remember, for the best quality single coil solenoid valve in India, consult a reputable supplier who prioritizes safety and performance.

Risk Assessment: Identifying Potential Failure Modes and Consequences

Ensuring the smooth operation of your system requires proactive risk assessment. A key element of this is identifying potential failure modes in your solenoid valves. By understanding these weaknesses, you can take steps to mitigate risks and prevent costly downtime.

- Identify Failure Modes: Consider how the Best Quality Single Coil Solenoid Valve in India could malfunction. This might include electrical issues, leakage, or mechanical sticking.

- Analyze Consequences: Evaluate the impact of each failure mode. A minor leak might cause a performance dip, while a complete valve failure could halt your entire operation.

- Prioritize Risks: Combine the likelihood of each failure with the severity of its consequences. Focus on addressing the highest-risk scenarios first.

By proactively identifying potential failure modes, you can take steps to prevent them. This might involve preventive maintenance, implementing redundant systems, or choosing high-quality valves like the Best Quality Single Coil Solenoid Valve in India.

Ensuring Proper Grounding and Insulation to Prevent Electric Shocks

Electricity is a powerful tool, but it demands respect. To prevent electrical shocks, proper grounding and insulation are crucial. Here's how they work together:

- Grounding: Creates a safe path for stray current to flow in case of a fault, diverting it away from you. Think of it as an escape route for unwanted electricity.

- Insulation: Coats wires and components, preventing current from leaking and potentially shocking you. It acts as a protective barrier.

- By ensuring both are in top condition, you significantly reduce the risk of electrical hazards.

Want the best quality for your project? Look no further! Explore the wide range of Best Quality Single Coil Solenoid Valves in India to keep your electrical systems safe and efficient. Remember, electrical work can be complex.

Implementing Lockout/Tagout Procedures for Maintenance and Repair

Performing maintenance and repairs safely is paramount. Lockout/Tagout (LOTO) procedures are a crucial step to prevent accidents caused by unexpected energy release. Here's a breakdown of the key steps:

- Preparation: Identify all energy sources (electrical, hydraulic, pneumatic) and potential hazards associated with the equipment.

- Shutdown: Follow proper procedures to shut down the equipment and isolate it from the power source.

- Isolation: Use physical locks and tags on energy isolating devices to prevent accidental reactivation.

- Verification: Ensure all energy sources are isolated and the equipment is safe to work on.

- Re-energization: Only after completing maintenance, follow LOTO procedures in reverse to safely restore power.

By implementing a comprehensive LOTO program, you can minimize risks and ensure a safe work environment for your team. Remember, for reliable control of fluid flow during maintenance, consider investing in India's Best Quality Single Coil Solenoid Valve.

Training Personnel on Safe Handling and Operation Practices

Equipping your personnel with the proper knowledge and skills is paramount to a safe and productive work environment. Here's how effective training on safe handling and operation practices benefits everyone:

- Reduced Risk: By identifying potential hazards and teaching proper techniques, you minimize the chance of accidents and injuries.

- Improved Efficiency: Well-trained staff operates equipment smoothly, leading to increased productivity and reduced downtime.

- Enhanced Morale: A safe workplace fosters a positive atmosphere where employees feel valued and supported.

For superior performance in pneumatic systems, consider using the best quality single coil solenoid valve in India. Look for valves built with durable materials and rigorous testing procedures to ensure long-lasting, reliable operation. By combining top-notch equipment with comprehensive safety training, you create a winning formula for success.

Emergency Response Planning for Solenoid Valve Malfunctions

Solenoid valves are crucial components in many industrial systems. A malfunction can cause significant disruptions and safety hazards. Here's how to plan for such emergencies:

- Identify Potential Failures: Understand the different ways a solenoid valve can malfunction (e.g., stuck open, stuck closed, leakage).

- Develop Response Procedures: Create clear procedures for each type of failure. This might involve manual shut-off valves, depressurization steps, or system isolation protocols.

- Train Personnel: Ensure all personnel who operate or maintain the system are trained on the emergency procedures. Regular refresher courses are essential.

- Maintain a Spare Parts Inventory: Keep critical spare parts, including Best Quality Single Coil Solenoid Valves in India, readily available for quick replacement.

- Test and Update: Regularly test your emergency response plan to ensure its effectiveness. Update the plan as needed based on operational changes or lessons learned from incidents.

By proactively planning for solenoid valve malfunctions, you can minimize downtime, ensure safety, and get your system back online quickly.

No comments yet