Aerospace component manufacturing is one of the challenging industrial tasks as it involves using high-quality, expensive materials and the high stakes of safety. Also, these components need to be lightweight and robust to withstand harsh conditions so that millions can fly safely worldwide. These aerospace components have complex geometries suitable for applications that need integrated functions. Examples include structural components acting as conduits, airfoils are also cooling channels, etc. So, using conventional manufacturing methods does not help, and only AM or additive manufacturing is best for making them with high-quality, cost-effective products. Hence, choosing the best aerospace component manufacturing companies is essential to have superior quality components that last for a long time and at competitive costs.

So, in this article, let us discuss aerospace component manufacturing and the many tips for choosing the best company with superior quality components to ensure safety and cost-effectiveness.

What is AM aerospace component manufacturing?

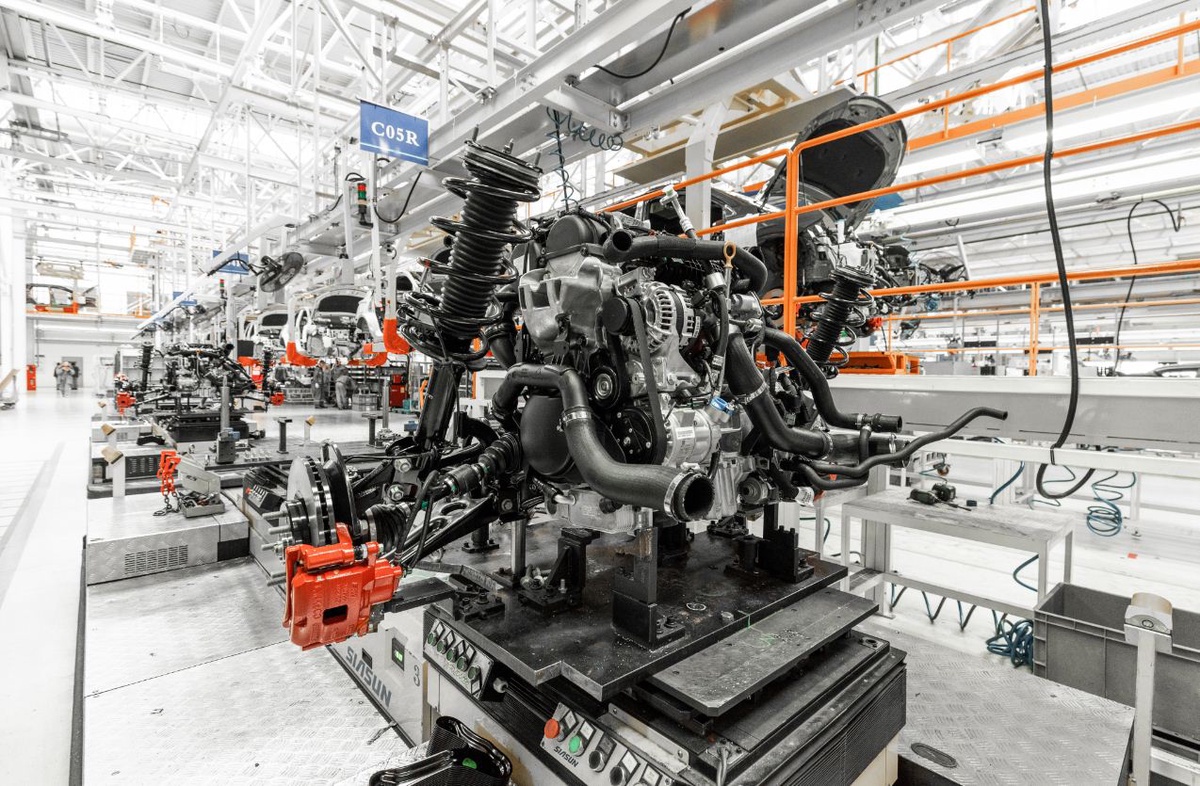

The global aerospace component market will become over a trillion dollars as soon as it crosses over 900 billion in 2023. However, making them with thin-walled structures with huge volume envelope-to-volume ratios is challenging. The conventional or subtractive methods are no longer helpful in aerospace component manufacturing, as AM or additive manufacturing is the new trend. AM's digital 3D or three-dimensional printing and CATIA models are revolutionizing the aerospace manufacturing industry. It is the reason that AM manufacturing in the aerospace market space is to be over 6.75 billion dollars by 2026, with a rapid CAGR growth of over 22%. There are many reasons, including making complex geometrical aerospace components simple with efficient prototyping to increase their internal strength, withstand harsh conditions, and be safe. Also, to make lightweight aerospace components with superior strength also cost-effectively.

Seven tips for choosing the best aerospace component manufacturing companies

With the stakes high in the aerospace industry, as safety is paramount for people to fly safely in the skies, choosing the best aerospace component manufacturing companies is critical. The following are a few tips on choosing the best among them to make aerospace component manufacturing as per the industry 4.0 norms and others.

- Check if the company uses additive aerospace component manufacturing to reduce many steps of the traditional making methods and save time and effort.

- Confirm if the component manufacturer uses CAD or computer-aided design for making digital 3-D models and CATIA or computer-aided three-dimensional interactive application, which is a revolutionizing tool for designing complex aerospace components effectively.

- Verify if the company makes aerospace components with integrated functions that play dual roles like structural components, conduits, and others efficiently.

- Check if the aerospace component manufacturing company has enough experience, as the stakes are high to have the trustworthiness of clients for a few decades.

- Confirm if the company uses high-quality raw materials like special alloys, nickel superalloys, titanium alloys, and others to make significant components like airframes and small ones like fasteners.

- Verify if the company produces difficult-to-machine aerospace components with a high ratio and short production runs using AM methods to save costs.

- Check if the company has an expert team of professionals passionate about advanced technology to use the latest equipment in state-of-the-art facilities using innovative engineering and international quality standards.

San Automotive has been one of India's leading aerospace component manufacturing companies in india for over two decades, with IATF 16949 certification, to make AM aerospace component manufacturing in its over 150,000 sq. ft state-of-the-art facility to make over 40,000,000 high-quality products per annum at competitive costs.

No comments yet