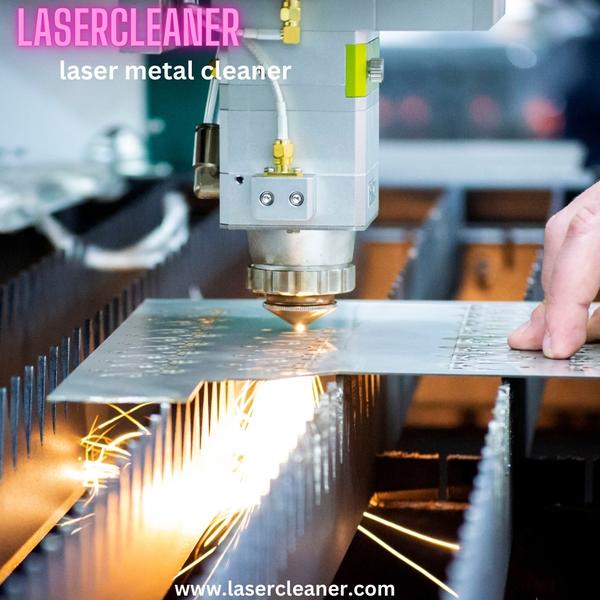

Laser metal cleaning is a cutting-edge technology that utilizes the power of laser beams to remove contaminants, rust, oxides, and unwanted layers from metal surfaces. This advanced method offers precision, efficiency, and environmental friendliness, making it a preferred choice for industries ranging from manufacturing to restoration. In this guide, we'll delve into the intricacies of laser metal cleaner, exploring its benefits, applications, and step-by-step process.

Benefits of Laser Metal Cleaning:

- Precision: laser metal cleaner allows for precise targeting of specific areas without damaging the underlying metal surface.

- Environmentally Friendly: Unlike traditional cleaning methods involving chemicals or abrasive materials, laser cleaning produces minimal waste and eliminates the need for harmful solvents.

- Cost-Effective: While the initial investment in laser equipment may be higher, the long-term savings in reduced labor, material costs, and maintenance make it a cost-effective solution.

- Versatility: Laser cleaning can be applied to a wide range of metals, including steel, aluminum, copper, and more, making it suitable for diverse industrial applications.

- Safety: With no direct contact between the cleaning tool and the metal surface, laser cleaning minimizes the risk of accidents or injury associated with traditional cleaning methods.

Step-by-Step Guide to Laser Metal Cleaning:

-

Preparation:

- Ensure the metal surface to be cleaned is free from any obstructions or debris.

- Set up the laser cleaning equipment in a well-ventilated area with proper safety measures in place.

-

Calibration:

- Adjust the laser parameters such as power, pulse duration, and beam diameter according to the specific requirements of the metal surface and contaminants.

-

Test Cleaning:

- Conduct a test cleaning on a small, inconspicuous area to determine the optimal laser settings and ensure the desired results without damaging the metal surface.

-

Cleaning Process:

- Position the laser cleaning tool at a suitable distance from the metal surface, ensuring proper focus and coverage.

- Activate the laser beam and scan it over the surface in a controlled manner, moving systematically to remove contaminants layer by layer.

- Monitor the cleaning progress closely, adjusting the parameters if necessary to achieve the desired level of cleanliness.

-

Inspection:

- After cleaning, inspect the metal surface thoroughly to ensure all contaminants have been removed and no damage has occurred.

- Repeat the cleaning process if needed to address any remaining residues or stubborn contaminants.

-

Post-Cleaning Treatment:

- Depending on the application and requirements, apply appropriate surface treatments such as coatings or protective finishes to enhance durability and corrosion resistance.

Conclusion: laser metal cleaner offers a revolutionary approach to surface preparation and restoration, combining precision, efficiency, and environmental sustainability. By following this comprehensive guide, you can harness the power of laser technology to achieve pristine metal surfaces across various industrial applications. Embrace the future of cleaning with laser technology and let your metal surfaces shine bright.

No comments yet