Steel Pipes Cannot Be Manufactured at Will

In order to manufacture a steel pipe, the raw material must be transformed into a more workable form. This is done through one of two processes: stretching the metal into a seamless tube or welding the edges together.

While both methods have their advantages, they also come with disadvantages. Fortunately, there are a few key differences that can help you determine which type of pipe is right for your needs.

Price

Steel pipes cannot be manufactured at will because they must be made using a precise process that is controlled by government standards. These standards ensure that the product is fit for its purpose and will not fail in a way that is unintended. The pipe must also pass a battery of mechanical tests that are designed to test its strength and chemical composition.

There are many different types of pipes that are used in a variety of applications. Some are used to transport liquids, while others are used to carry heavy loads. The best type of pipe for your project depends on the environment and the application.

Seamless pipes are a popular option because they can be purchased at a lower price than welded pipes. They are also more durable, which is important for a range of applications.

Stainless steel is another type of pipe that is used brass bush for transporting liquids and is very resistant to corrosion and is easy to clean. This material is also very lightweight and can withstand high pressures without breaking or cracking.

Some other options for transporting fluids include galvanized steel, which is highly corrosion-resistant and can withstand long periods of exposure to harsh conditions. However, this material can be expensive, so it's important to choose the right type of pipe for your needs.

Welded pipes are another type of pipe that is commonly used in industrial and commercial applications. They are typically cheaper than seamless pipes, and they are easier to fabricate. They can be shaped by bending machines and rollers, and they are also easily welded together.

There are many different types of welded steel pipes, including round, square, rectangular, and oval. These pipes can be made from either a hot-rolled or cold-drawn sheet of steel.

The cost of a pipe can vary significantly, depending on its size and quality. Some of the factors that determine its cost are the manufacturing process, the number of seams it contains, and its pressure rating.

Steel is a versatile material that can be used in a wide variety of applications. It can be welded, pierced, or extruded, and it is also a popular choice for transporting liquids. This makes it a great choice for industries that require the use of pipes and tubes, such as industrial, medical, military, transportation, and architecture.

Durability

Steel is used to make a wide range of products from buildings to machinery, and it’s an invaluable resource for many sectors. Among its many properties, one of the most important is its durability.

While some metals deteriorate quickly due to exposure to weather and soil, stainless steel pipes are unlikely to rust or corrode in most environments. In fact, they often last for decades without needing to be replaced.

In addition, they are able to resist chemicals and other substances that could damage or destroy them. This makes them an excellent choice for sanitary water and wastewater distribution systems, as well as hospitals and other areas where people need clean drinking water.

Moreover, they can be recycled multiple times to keep them in good condition. This is important in an environmental context as it helps reduce the amount of waste produced in landfills.

This type of steel is also a lot more durable than other types of metal, such as iron, because it’s resistant to cracking and bursting. This means that it can withstand much higher pressure and vibrations than other materials, which is important when used in industries like shipbuilding where it may come into contact with harsh weather conditions.

Finally, steel is also a non-combustible material, which makes it safer to use in building structures. It is also more resistant to termites and other pests than other materials, which can cause structural failure.

Another advantage of using steel in a construction project is that it can be cheaper malleable iron fittings to purchase than other materials. This is because steel can be made thinner than other materials, which increases its carrying capacity with the same dimensions. This can be a big money-saver for businesses that need to provide a consistent amount of water flow over long periods of time.

Choosing the right type of steel pipe for your needs can be confusing, especially since there are so many different types available. This is why it’s important to understand their different properties and their applications so you can choose the best for your needs.

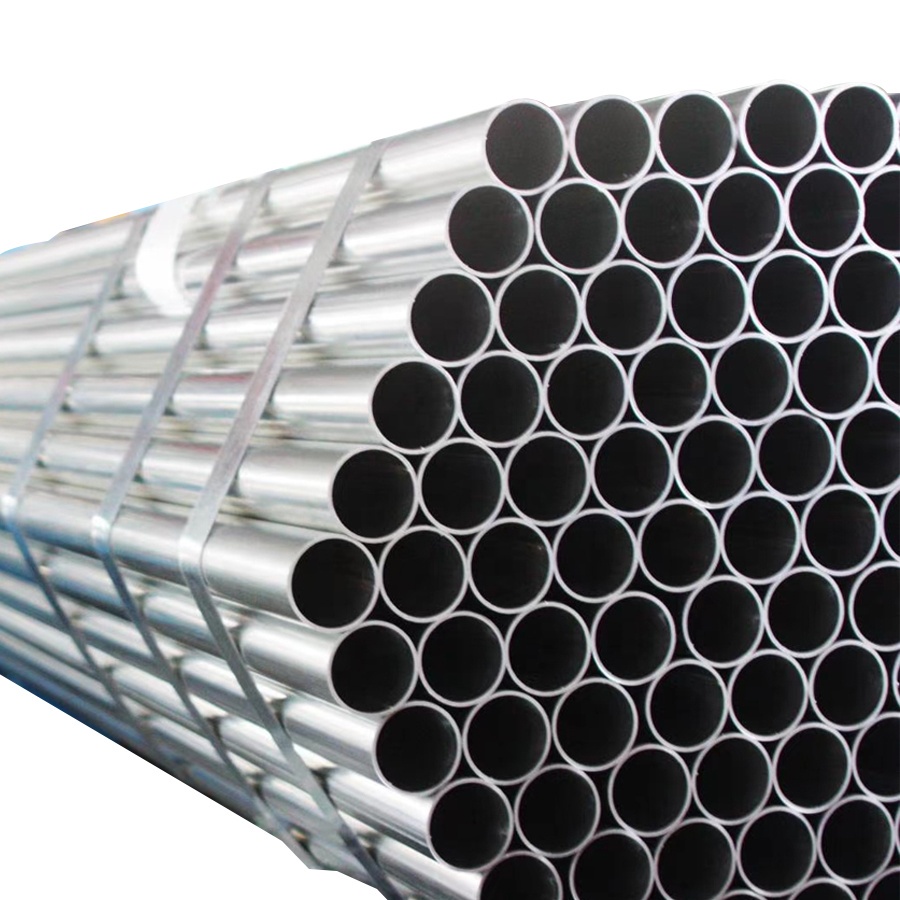

image source https://www.pinterest.ph/

Resistance to Corrosion

The resistance of steel pipes to corrosion depends on the manufacturing process and chemical composition. Stainless steel is a type of steel that includes chromium and other elements that form a protective passivation layer on the surface of the metal. This layer is too thin to see with the naked eye, but it does help to protect stainless steel from corrosion by forming a shield-like coating on the surface.

Stainless steel is used in a wide range of applications because it can resist the corrosion caused by water, oil and other chemicals. This makes it an ideal choice for sanitary water distribution and other corrosive processes, and can extend the life of equipment in these areas.

While stainless steel is resistant to corrosion, it is still susceptible to pitting, which occurs when small holes or cavities in the metal are pierced by corrosion. This condition can cause stress cracking and damage if it occurs at critical points in the system, so it is important to choose the right type of steel for your piping needs.

There are several different types of stainless steel, including 304 and 316, which offer the best levels of corrosion resistance. These materials can be welded using electric resistance welding (ERW) or high-frequency induction welding (HFI).

Other types of stainless steel include bimetallic combination tubing and stainless alloy steel, which have different levels of corrosion resistance. These materials are commonly used in industrial applications with Brass fitting, such as hydronic systems that are exposed to high temperatures and pressures.

Another way to increase the corrosion resistance of stainless steel is to use a post-weld heat treatment after welding. This can help to minimize weld decay and prevent precipitation during the fusion process, both of which can cause corrosion.

Regardless of the method you choose, it is vital to ensure that your stainless steel pipe is properly inspected before installing it in your system. If you do not, you may end up with a system that is more expensive to maintain and less durable than it could be.

There are three main manufacturing methods for welded pipe, including butt-welded, double submerged arc welded (DSAW) and electric resistance welded (ERW). The most common and widely used is ERW, which uses an electrical current to weld the seams of the steel.

image source https://www.pinterest.ph/

Environmental Impact

Steel pipes cannot be manufactured at will because they must be carefully planned. This means determining where the pipe will be installed and what materials it will need to survive. If a pipe is not constructed right, it could cause environmental issues in the long run.

The environment must be protected from any leaks that could damage water or cause a spillage of toxic material. This is why pipelines are built using advanced materials, engineering and inspection techniques to keep water safe.

These techniques include drilling deep into the ground, horizontal directional drilling (HDD), special coatings and continuous monitoring and inspections. Even if a leak is discovered, there are ways to repair it before the problem worsens and could cause more damage.

Another factor to consider is how the pipe will be used and its expected lifespan. If it will be used to transport corrosive liquids, the pipe may need to be made from a more specialized metal than normal.

This is the case for carbon and alloy steels. These types of materials have specific strengths, such as strength to tensile load and yield strength. They are also available in different wall thicknesses to match the application.

A good quality pipe will be able to withstand high pressure and be resistant to rusting. This will help to ensure the pipe remains intact for a longer period of time and that it does not require any maintenance.

Alloy steels contain nickel (Ni), which improves the hardness of the steel and increases its oxidation resistance. Ni can also be added to low-carbon steels to increase their ductility.

Stainless steels are used for a wide range of applications, including oil and gas pipelines, transmission lines, sanitary sewer lines and water supply pipes. They have high resistance to rust, corrosion, and scale formation.

There are many different types of steel pipe, and each has its own strengths and uses of Electrical Conduit. However, they are all designed to withstand a certain amount of pressure and prevent leaks. They are also resistant to a variety of environments. This is why they are so popular for use in transportation.

No comments yet