Hello readers, we all know that safety measures have become the prime step in various industrial and commercial spaces. The industrial test and tag process is a crucial step in ensuring electrical safety in the workplace.

This blog post will provide you with a comprehensive checklist of everything you need to know about industrial test and tag, including its importance, the process involved, and the benefits it brings.

So, let's dive in and learn more about Industrial test and tag Adelaide service!

Understanding Industrial Tests and Tag

Industrial test and tag refer to inspecting, testing and tagging electrical equipment in the workplace to ensure its safety. This is done by a qualified professional who checks for any potential faults or hazards in electrical devices and ensures their compliance with safety regulations.

Importance of Industrial Test and Tag

Ensuring electrical safety in industrial settings is paramount, as electrical accidents can lead to injuries, property damage, and even loss of life. The industrial test and tag Adelaide process helps identify any electrical faults or defects that could pose a risk, allowing for timely repairs or replacement of faulty equipment. It also ensures compliance with safety standards and regulations, reducing the likelihood of accidents or electrical hazards in the workplace.

The Industrial Test and Tag Checklist

To ensure a thorough and effective industrial test and tag process, the following checklist should be followed:

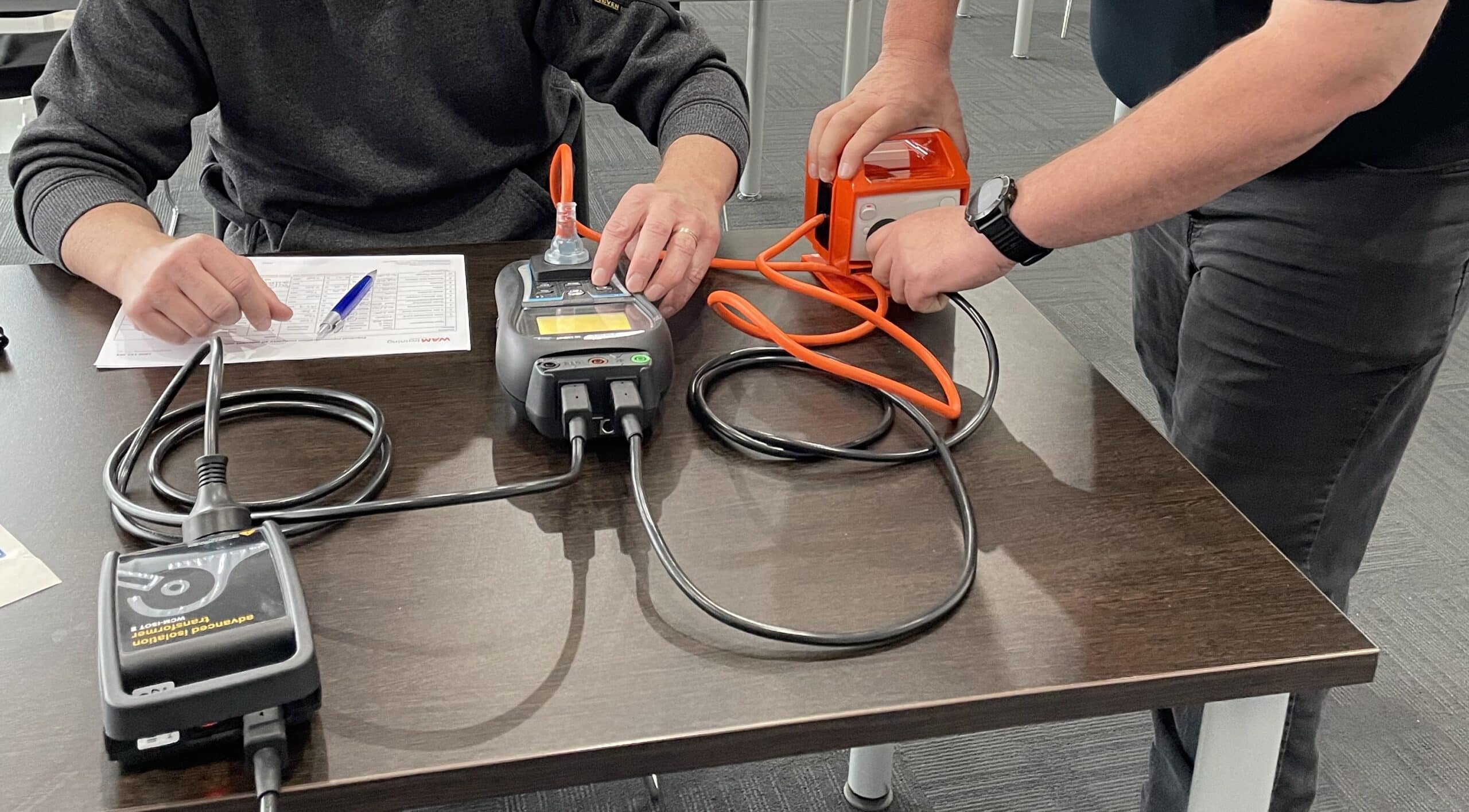

- Visual Inspection: Begin by visually inspecting all electrical equipment for any visible signs of damage, such as frayed cords, broken plugs, or loose connections. If any issues are found, the equipment should be taken out of service for repair or replacement.

- Electrical Testing: Conduct a series of electrical tests to assess the safety and functionality of the equipment. This typically includes tests for insulation resistance, earth continuity, and polarity. Testing should be performed using specialised equipment by a qualified electrician or test and tag professional.

- Tagging and Labelling: After a piece of equipment has been tested and deemed safe, it should be tagged and labelled accordingly. This involves attaching a durable tag or label that indicates the test date, the next due date for retesting, and other relevant information.

- Documentation: Maintain detailed records of all tested and tagged equipment, including the date of testing, the results, and any repairs or maintenance performed. This documentation helps track equipment status and ensures safety regulations compliance.

- Regular Retesting: Electrical equipment should be regularly retested according to the recommended intervals or legislative requirements. This ensures that equipment remains safe and complies with safety standards over time.

Benefits of Industrial Test and Tag

Implementing a thorough industrial test and tag process brings several benefits to businesses:

- Safety and Risk Mitigation: By identifying and addressing electrical faults, the test and tag process reduces the risk of accidents, injuries, and damage caused by faulty equipment.

- Compliance with Regulations: Compliance with safety regulations is essential for businesses to avoid penalties and ensure a safe working environment. For example, to have a fire hose reel in Adelaide to maintain safety.

- Increased Equipment Lifespan: Regular testing and maintenance prolong the lifespan of electrical equipment, reducing the need for premature replacement.

- Peace of Mind: Knowing that electrical equipment has been tested and deemed safe provides peace of mind for both employers and employees, creating a safer work environment.

- Improved Productivity: Well-maintained and safe electrical equipment contributes to uninterrupted workflow and increased productivity.

Final Thoughts

In conclusion, industrial testing and tagging is a critical process that ensures electrical safety in the workplace. By following a comprehensive checklist that includes visual inspections, electrical testing, tagging and labelling, documentation, and regular retesting, businesses can ensure the safety of their workers and compliance with regulations. The benefits of test and tag extend beyond security, offering increased equipment lifespan, peace of mind, and improved productivity. Prioritising the industrial test and tag Adelaide process is a wise investment in a safer and more efficient workplace.

No comments yet