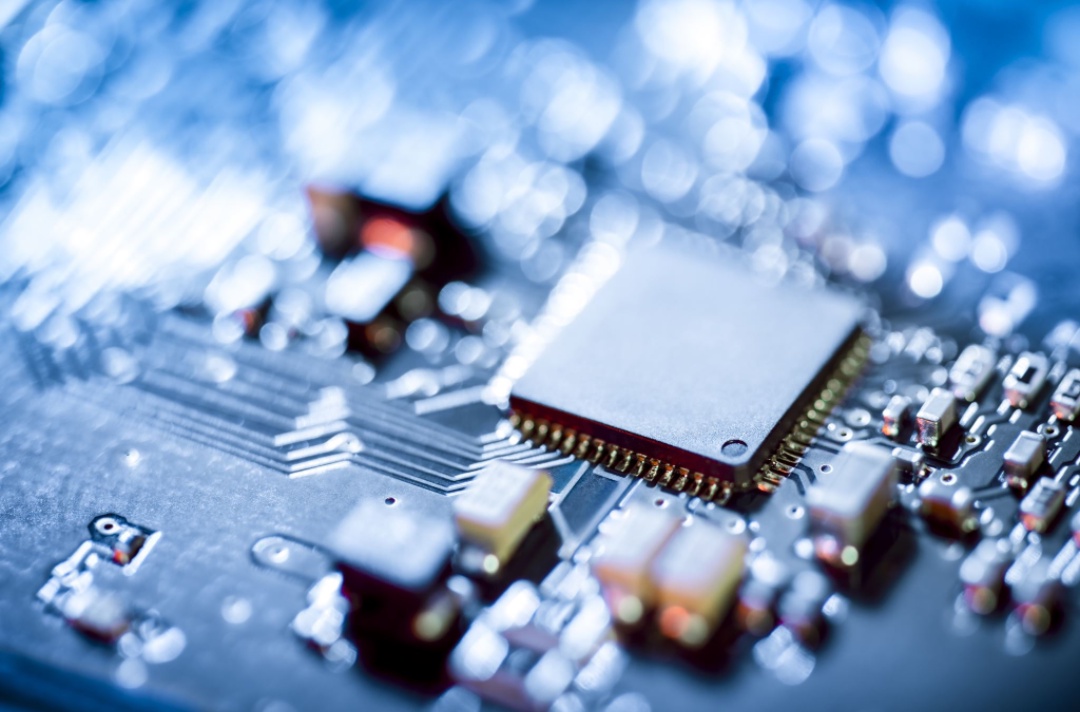

Printed Circuit Board (PCB) assembly plays a critical role in the electronics industry, serving as the backbone of countless electronic devices we use in our daily lives. From smartphones to laptops, medical devices to automotive systems, PCBs are essential components that facilitate the flow of electric signals between different electronic components. In this guest post, we will explore the world of PCB assembly services, discussing its significance, evolution, and the advancements that have transformed the industry.

Understanding PCB Assembly

PCB assembly, also known as PCBA or printed circuit board assembly, is the process of mounting electronic components onto the surface of a bare PCB. It involves soldering various components, such as resistors, capacitors, integrated circuits, and connectors, onto the board to create a functional electronic circuit.

The PCB assembly process can be broadly classified into two main types: through-hole assembly and surface mount technology (SMT) assembly. Through-hole assembly involves inserting leads of components through holes on the PCB and soldering them on the opposite side. On the other hand, SMT assembly involves soldering components directly onto the surface of the PCB, eliminating the need for drilled holes.

The Importance of PCB Assembly Services

Precision and Reliability: printed circuit board assembly requires a high level of precision and attention to detail. The quality of assembly directly impacts the performance, reliability, and longevity of electronic devices. Professional PCB assembly services ensure that components are accurately placed, and soldering is done with utmost precision.

Time Efficiency: Outsourcing PCB assembly to specialized manufacturers allows companies to focus on their core competencies, leading to increased time efficiency and faster product development cycles.

Cost-effectiveness: By partnering with PCB assembly manufacturers, companies can reduce the cost of equipment, labor, and maintenance associated with in-house assembly. This cost-effective approach enables businesses to allocate resources efficiently.

Evolution of PCB Assembly Services

The PCB assembly industry has witnessed remarkable transformations over the years, driven by advancements in technology and customer demands. Let's explore some key developments:

Surface Mount Technology (SMT) Revolution: SMT assembly replaced through-hole assembly as the dominant method due to its higher component density and reduced size. This shift allowed for more compact and lightweight electronic devices.

Automation and Robotics: Automation and robotics have revolutionized PCB assembly, enhancing efficiency and accuracy. Automated pick-and-place machines can precisely position components at a rapid pace, significantly reducing assembly time.

High-Volume PCB Assembly: With the rise of consumer electronics, the demand for high-volume PCB assembly surged. Manufacturers have adapted their processes to handle large-scale production efficiently.

Miniaturization: Advancements in miniaturization have been critical in the electronics industry. Smaller components and intricate designs have challenged PCB assembly providers to develop innovative techniques and invest in cutting-edge machinery.

Lead-Free Soldering: Environmental concerns prompted the industry to transition from lead-based soldering to lead-free alternatives, making electronic devices more eco-friendly.

Advancements in PCB Assembly Services

Advanced Materials: The use of advanced materials, such as high-temperature laminates, flexible substrates, and high-frequency materials, has enabled the assembly of PCBs with enhanced performance in specialized applications like aerospace, telecommunications, and automotive industries.

3D Printing Technology: The integration of 3D printing technology into PCB assembly has enabled the creation of complex and customized structures, reducing the need for multiple boards and connectors.

Internet of Things (IoT) Integration: PCB assembly services have adapted to the IoT era, accommodating the production of smart devices with interconnected capabilities.

Artificial Intelligence and Machine Learning: AI-driven algorithms are utilized for automated inspection of PCBs, detecting defects, and ensuring the highest quality during the assembly process.

Environmental Sustainability: PCB assembly services are embracing environmentally friendly practices, such as recycling electronic waste and reducing energy consumption during production.

Conclusion

PCB assembly services have played an indispensable role in shaping the electronics industry, enabling the development of cutting-edge technologies that have transformed the way we live and work. From the early days of through-hole assembly to the current era of advanced SMT technology and AI-driven quality control, the evolution has been remarkable. As technology continues to advance, we can expect further innovations in PCB assembly that will drive the future of electronics and contribute to a more interconnected world.

No comments yet