In the vast landscape of metalworking, plate bending machines represent a pivotal advancement, shaping the way we manipulate and form metal plates. From simple manual tools to sophisticated hydraulic plate bending machines, the evolution of this technology has revolutionized manufacturing processes worldwide. Join us as we delve into the history, mechanics, and significance of plate bending machines, exploring their role in modern industrial operations.

Introduction to Plate Bending Machines

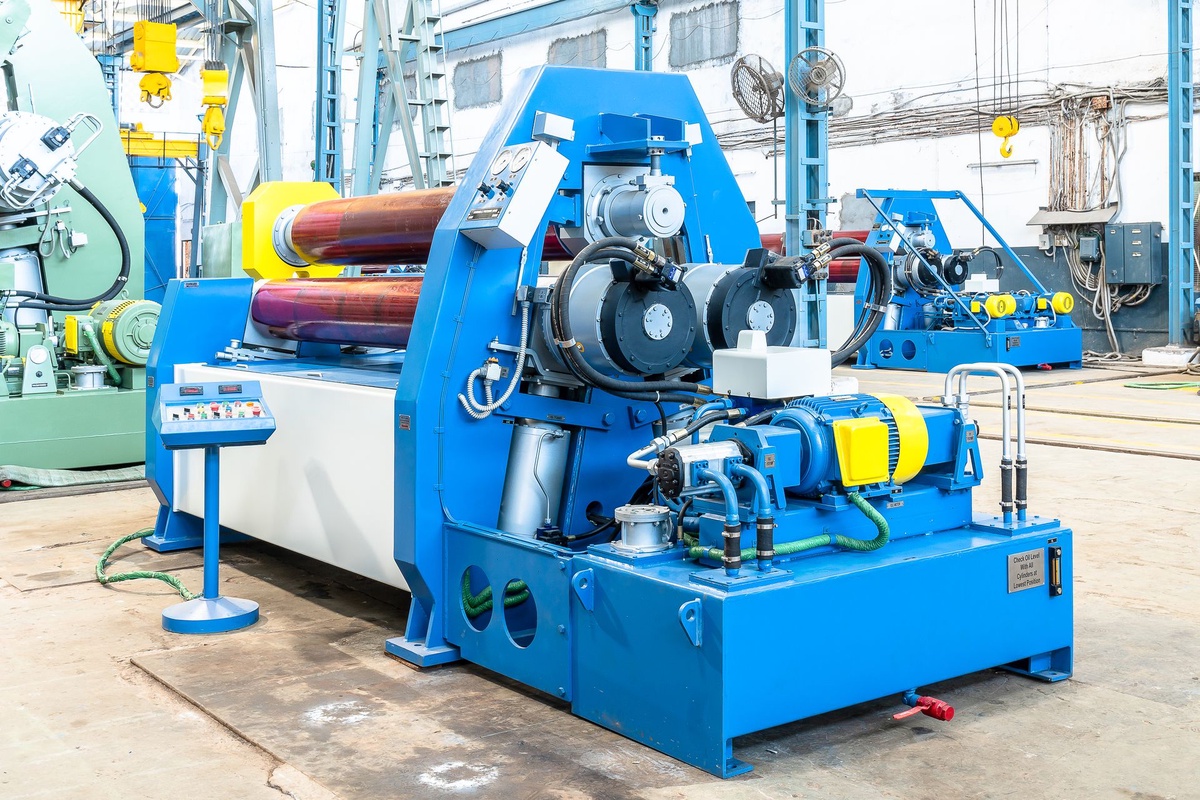

Plate bending machines, such as the 4 Roller Bending Machine and hydraulic plate bending machine, are essential tools in metal fabrication. They enable the bending and shaping of metal plates with precision and efficiency. This article explores the journey of these machines and the impact they have had on metal manufacturers globally.

The Early Days of Metalworking

Centuries ago, metalworking was a manual craft involving primitive tools. Skilled artisans hammered and shaped metal plates by hand, a labor-intensive process with limited precision. The need for more efficient methods spurred the development of mechanized solutions.

Emergence of Plate Bending Machines

The 19th century marked a turning point with the introduction of mechanical plate bending machines. Plate bending machine manufacturers like Himalaya Machinery pioneered innovations that automated plate bending, significantly increasing productivity. These early machines laid the groundwork for modern advancements.

Types of Plate Bending Machines

Plate bending machines come in various forms, each catering to specific manufacturing needs. The 4 Roller Bending Machine stands out for its ability to achieve precise bends without material slippage. Hydraulic plate bending machines leverage hydraulic systems for enhanced control and power.

Mechanics Behind Plate Bending

Understanding the mechanics is key to appreciating these machines. A plate bending machine exerts force on metal plates, causing them to deform gradually. Rollers or hydraulic systems aid in this process, shaping the metal according to predetermined specifications.

Evolution of Hydraulic Plate Bending Machines

The integration of hydraulic technology transformed plate bending. Hydraulic plate bending machines offer unparalleled control, enabling operators to achieve complex bends with ease. This innovation ushered in a new era of efficiency and accuracy in metal fabrication.

Advantages of 4 Roller Bending Machines

The 4 Roller Bending Machine is favored for its ability to perform pre-bending and final bending in a single pass. This reduces handling and setup times, increasing throughput in manufacturing operations. Additionally, the four-roll design ensures uniform bending across the entire length of the plate.

Applications in Various Industries

Plate bending machines find extensive use across diverse industries. From shipbuilding and aerospace to construction and automotive sectors, these machines are indispensable for forming structural components and vessel hulls with precision.

Understanding the Rolling Process

The rolling process involves feeding metal plates through rollers that gradually bend them into desired shapes. Plate bending machines facilitate this process, allowing for the creation of cylindrical and conical shapes used in a myriad of applications.

Innovations in Modern Plate Bending Machines

Modern plate bending machines incorporate advanced features like CNC controls and automated adjustments. These enhancements optimize workflow efficiency and reduce material waste, making them essential assets in today's competitive manufacturing landscape.

Impact on Metal Manufacturing

The adoption of plate bending machines has redefined metal manufacturing practices. Companies benefit from increased production capacities, improved quality control, and reduced lead times, translating into cost savings and enhanced competitiveness.

Sustainability and Plate Bending Machines

Efficient use of resources is paramount in modern industry. Plate bending machines contribute to sustainability by minimizing material waste and energy consumption. Precision bending ensures optimal use of raw materials, aligning with eco-conscious manufacturing principles.

Future Trends in Metalworking

Looking ahead, the future of plate bending machines is exciting. Expect further integration of IoT technologies for predictive maintenance and real-time monitoring. Automation will continue to streamline processes, unlocking new possibilities in metal fabrication.

Conclusion

The evolution of plate bending machines underscores the relentless pursuit of efficiency and precision in metalworking. From humble beginnings to cutting-edge innovations, these machines have left an indelible mark on the industry, empowering manufacturers to push boundaries and realize their creative visions.

Frequently Asked Questions (FAQs)

1. What is a plate bending machine?

A plate bending machine is a mechanical tool used to bend metal plates into various shapes, such as cylinders or cones, through controlled deformation.

2. How does a hydraulic plate bending machine work?

A hydraulic plate bending machine uses hydraulic power to exert controlled force on metal plates, enabling precise bending without material damage.

3. What are the advantages of a 4 Roller Bending Machine?

The 4 Roller Bending Machine offers superior pre-bending capabilities, reducing setup times and improving efficiency in metal fabrication processes.

4. Where are plate bending machines used?

Plate bending machines are utilized across industries such as shipbuilding, aerospace, construction, and automotive manufacturing to shape metal components.

5. How has the rolling process evolved with plate bending machines?

Plate bending machines have refined the rolling process, allowing for more complex shapes and greater precision in metal fabrication.

No comments yet