Introduction:

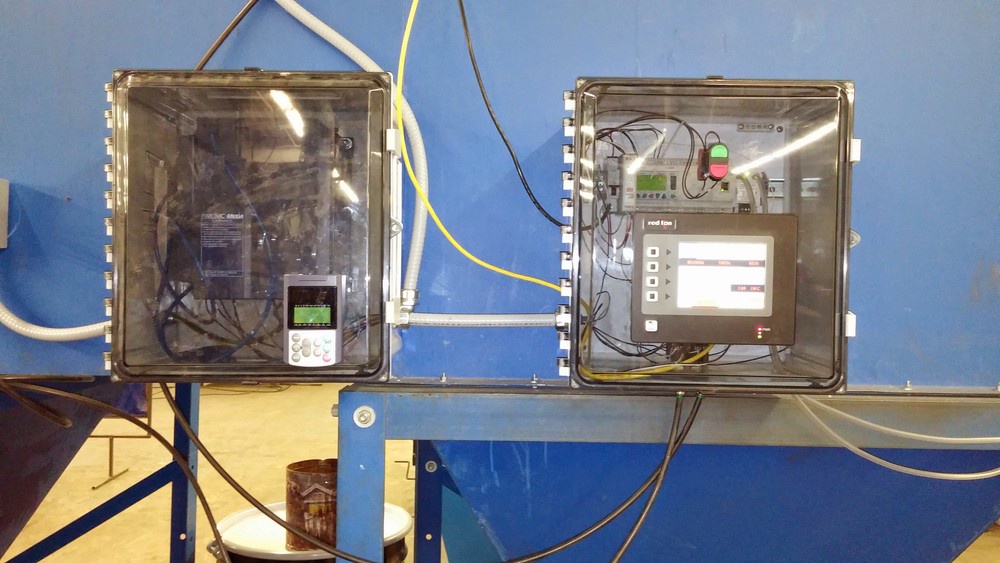

In today's modern world, human-machine interaction (HMI) control panels have become an integral part of various industries, including manufacturing, healthcare, and transportation. These control panels provide a user-friendly interface to monitor and control complex machinery and processes. However, the history of HMI control panels dates back to the 1940s, when the first computers were developed. Since then, these panels have evolved significantly, and this article will explore their history, applications, and the latest technological advancements.

History of HMI Control Panels:

The first HMI control panels were developed in the 1940s to control the early computers. These panels were simple and consisted of switches and knobs, which allowed operators to input data and control the computer's operations. As computers became more sophisticated, the control panels also evolved, incorporating more advanced features such as displays and touch screens.

The development of the integrated circuit (IC) enabled hmi control panels the creation of more powerful and compact control panels. These panels were used in various industries, including manufacturing, to control the machines' operations. However, these control panels were not user-friendly, and operators had to undergo extensive training to use them effectively.

The development of microprocessors

And graphic displays revolutionized the HMI control panels' design. These panels incorporated graphical user interfaces (GUI), which made them more intuitive and user-friendly. The GUI allowed operators to interact with the machines' operations using icons and visual representations, making it easier to monitor and control the machines' operations.

Applications of HMI Control Panels:

HMI control panels are used in various industries, including manufacturing, healthcare, transportation, and aerospace. In manufacturing, these panels are used to control the operations of machines such as conveyor belts, robots, and assembly lines. The panels provide real-time data on the machines' operations, allowing operators to monitor and control the machines' performance.

In healthcare

HMI control panels are used to monitor patients' vital signs, including heart rate, blood pressure, and oxygen levels. The panels provide real-time data to healthcare professionals, allowing them to make informed decisions on patient care.

In transportation

HMI control panels are used in vehicles, including airplanes, cars, and trains, to monitor and control the vehicles' operations. The panels provide real-time data on the vehicles' speed, altitude, and fuel levels, allowing operators to make informed decisions on the vehicles' operations.

In aerospace

HMI control panels are used in spacecraft to monitor and control the spacecraft's operations. The panels provide real-time data on the spacecraft's position, orientation, and velocity, allowing operators to make informed decisions on the spacecraft's trajectory.

Technological Advancements in HMI Control Panels:

The latest technological advancements in HMI control panels have made them more powerful, efficient, and user-friendly. Some of the notable advancements include:

Touch Screen Technology: Touch screen technology has revolutionized the design of HMI control panels. The touch screen allows operators to interact with the machines' operations by simply touching the screen. This technology has made the control panels more intuitive and user-friendly.

Wireless Communication: The integration of wireless communication technology has made HMI control panels more flexible and mobile. Operators can now monitor and control machines' operations from remote locations, improving efficiency and reducing downtime.

Internet of Things (IoT): The integration of IoT technology has enabled HMI control panels to communicate with other devices and systems, such as sensors and servers. This technology has allowed operators to monitor and control machines' operations in real-time, improving efficiency and reducing downtime.

Artificial Intelligence (AI): The integration of AI technology has enabled HMI control panels to make autonomous decisions based on real-time data. This technology has improved.

In conclusion

HMI control panels have come a long way since their inception in the 1940s. The development of new technologies such as touch screens, wireless communication, IoT, AI, AR, and voice recognition has revolutionized the design of HMI control panels, making them more powerful, efficient, and user-friendly. These advancements have also improved the overall performance of machines, reducing downtime and increasing productivity. As technology continues to advance, HMI control panels will continue to evolve, improving the efficiency and performance of machines in various industries.

No comments yet