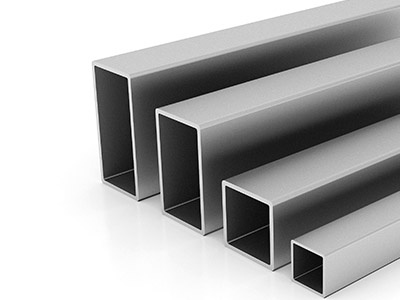

Galvanized Plain (GP) pipes are gaining increasing recognition across various sectors for their reliability, strength, and resistance to environmental factors. These pipes, known for their high-quality zinc coating, serve as a crucial component in applications ranging from construction to automotive systems.

What Are GP Pipes?

GP pipes, or Galvanized Plain pipes, are made from steel or iron that has been coated with zinc. This coating is typically applied through a hot-dip galvanizing process, where the pipes are submerged in molten zinc. This layer of zinc provides a protective barrier against corrosion, making the pipes more durable and suitable for use in harsh environments.

Types of GP Pipes

-

Hot-Dip Galvanized GP Pipes: These pipes receive a thick coating of zinc that adheres strongly to the base metal through a hot-dip process. They are known for their superior resistance to corrosion and are ideal for outdoor and industrial applications.

-

Pre-Galvanized GP Pipes: Manufactured by galvanizing the steel sheets before they are formed into pipes. This method ensures a uniform coating of zinc, making it suitable for interior applications and where physical appearance is important.

Applications of GP Pipes

GP pipes are versatile and find applications in several key areas:

-

Construction and Infrastructure: Used extensively in building frameworks, fencing, and railings, GP pipes contribute to the structural integrity and longevity of constructions.

-

Automotive Industry: These pipes are employed in the manufacturing of vehicle components that require corrosion resistance and durability under various environmental conditions.

-

Agricultural and Irrigation Systems: Farmers use GP pipes for irrigation systems as they are robust against rust and can endure the exposure to fertilizers and harsh weather conditions.

-

Telecommunications: Protecting underground cables and wires from moisture and physical damage, GP pipes ensure the reliability of telecommunications infrastructure.

Advantages of GP Pipes

The benefits of using GP pipes in projects are significant:

-

Durability: The zinc coating provides excellent protection against rust and extends the life of the pipes, even under stressful conditions.

-

Economical: GP pipes are cost-effective compared to other corrosion-resistant pipes, such as stainless steel. This makes them a popular choice for budget-sensitive projects.

-

Maintenance-Free: Once installed, GP pipes require little to no maintenance due to their robust nature, which reduces long-term costs.

-

Environmental Resistance: They perform well in a variety of environments, resisting damage from UV light, moisture, and chemical exposure.

Future Trends

The demand for GP pipes is expected to grow as more industries recognize their benefits. Innovations in galvanizing technology may lead to even more efficient and environmentally friendly processes, increasing the pipes' utility and appeal. Additionally, as global infrastructure development continues to accelerate, the need for durable, cost-effective building materials like GP pipes is likely to increase.

In conclusion, GP pipes are proving to be an invaluable resource in numerous fields due to their durability, cost-efficiency, and resistance to environmental factors. As technology advances and the scope of applications expands, the significance of GP pipes in global industries is set to rise, underscoring their role in building a resilient and sustainable future.

More Read: Gp pipe | gp pipe manufacturers

No comments yet