Introduction

Technology has transformed nearly every industry, and the field of mechanical contracting is no exception. As one of the critical pillars of the construction sector, mechanical contracting involves the installation, maintenance, and repair of mechanical systems in buildings, including heating, ventilation, air conditioning (HVAC), plumbing, and electrical systems. In recent years, advancements in technology have revolutionized the way mechanical contractors operate, offering a wide range of tools, software, and equipment that enhance efficiency, accuracy, and overall project management. From advanced modeling and simulation software to the use of drones and robotics, the impact of technology on mechanical contracting is undeniable, leading to increased productivity, cost savings, and improved quality in construction projects.

One of the significant impacts of technology on mechanical contracting is the introduction of Building Information Modeling (BIM) systems. BIM allows mechanical contractors to create digital representations of a building's physical and functional characteristics before construction begins. This technology enables contractors to visualize the entire project, including mechanical systems, and identify potential clashes or design issues early on, reducing costly rework and delays. BIM also facilitates collaboration among various stakeholders, such as architects, engineers, and contractors, by providing a centralized platform to share and update project information in real-time. This integration of technology streamlines the planning, coordination, and execution of mechanical systems, leading to improved project outcomes and client satisfaction.

Automation and Efficiency in Project Planning

Automation has revolutionized project planning in the field of mechanical contracting, enabling greater efficiency and accuracy in the process. With the advent of sophisticated software and tools, mechanical contractors can automate various aspects of project planning, including scheduling, resource allocation, and cost estimation. By leveraging these automated systems, contractors can streamline their workflow, eliminate manual errors, and save valuable time in the planning phase. The ability to quickly generate accurate project schedules, allocate resources effectively, and estimate costs with precision empowers mechanical contractors to optimize their operations, meet deadlines, and deliver projects within budget.

Moreover, automation in project planning allows for better resource management and utilization. Advanced software applications can analyze historical project data, identify patterns, and make intelligent predictions about resource requirements for future projects. This data-driven approach enables contractors to allocate resources efficiently, ensuring that the right personnel, equipment, and materials are available at the right time and in the right quantities. By eliminating guesswork and optimizing resource allocation, automation contributes to increased productivity, reduced waste, and improved project outcomes. Additionally, automation systems can generate real-time reports and dashboards, providing stakeholders with up-to-date information on project progress, allowing for proactive decision-making and effective communication throughout the planning process.

Advanced Building Information Modeling (BIM) for Design and Coordination

Advanced Building Information Modeling (BIM) has revolutionized design and coordination in the field of mechanical contracting. BIM offers a comprehensive and digital representation of a building, integrating architectural, structural, and mechanical systems into a single, collaborative platform. With advanced BIM software, mechanical contractors can create detailed 3D models of mechanical systems, allowing for enhanced visualization and understanding of how different components interact within the building. This level of detail facilitates more accurate design, as potential clashes or conflicts can be identified and resolved early in the planning stage, saving time and avoiding costly rework during construction.

Furthermore, advanced BIM tools enable seamless coordination among various stakeholders involved in the construction project. Architects, engineers, mechanical contractors, and other professionals can work collaboratively within the BIM environment, sharing and exchanging information in real-time. This integrated approach eliminates communication gaps, enhances collaboration, and ensures that all parties are working towards a common goal. Changes made to the design or specifications are instantly updated across the model, allowing for quick and efficient decision-making. As a result, the overall coordination and synchronization of mechanical systems with other building components are significantly improved, leading to smoother construction processes and minimizing potential conflicts or delays.

Enhanced Equipment and Tools for Construction and Installation

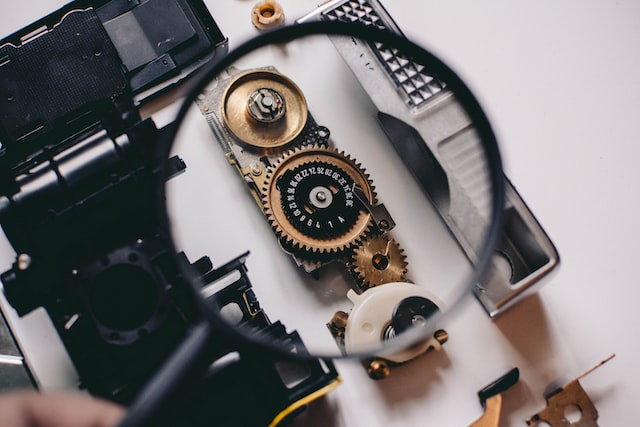

The advancements in technology have brought forth a wide array of enhanced equipment and tools that have revolutionized the construction and installation processes in the field of mechanical contracting. These cutting-edge tools and equipment offer numerous benefits, including increased efficiency, accuracy, and safety. For instance, the development of advanced power tools, such as cordless drills, impact wrenches, and pipe threading machines, has significantly expedited the installation process for mechanical systems. These tools are more powerful, portable, and user-friendly, enabling contractors to complete tasks swiftly and with precision, ultimately reducing project timelines and labor costs.

Additionally, specialized equipment like robotic systems and drones have emerged as invaluable assets in mechanical contracting. Robotic systems can perform repetitive or physically demanding tasks with exceptional accuracy and speed. They can be employed in various applications, including welding, pipe cutting, and HVAC system installation. Drones, on the other hand, offer an efficient means of conducting inspections and surveys of construction sites, providing aerial footage and data that aid in project planning and monitoring. These advanced equipment and tools not only enhance productivity and efficiency but also improve safety by minimizing the risk of accidents and injuries associated with manual labor.

IoT and Sensors

The advent of the Internet of Things (IoT) and sensor technology has had a profound impact on the operations of mechanical contractors in Dallas and beyond. By integrating IoT devices and sensors into mechanical systems, contractors can gather real-time data on performance, energy consumption, and maintenance needs. These devices enable remote monitoring and control of mechanical systems, allowing contractors to proactively identify and address issues before they become major problems. For example, sensors can detect changes in temperature, humidity, or pressure, triggering automatic adjustments or alerts to prevent equipment failures or inefficiencies. The use of IoT and sensors enhances the overall reliability, efficiency, and sustainability of mechanical systems, while also reducing downtime and maintenance costs.

Furthermore, IoT and sensor technology facilitates predictive maintenance in mechanical contracting. By continuously monitoring equipment performance and collecting data, contractors can leverage predictive analytics to anticipate maintenance needs and schedule repairs or replacements proactively. This proactive approach eliminates the need for reactive maintenance, where repairs are done only after a breakdown occurs. Predictive maintenance not only saves time and resources but also extends the lifespan of mechanical systems, optimizing their performance and reducing the likelihood of costly emergencies. The integration of IoT and sensors empowers mechanical contractors dallas to deliver high-quality services, maximize equipment uptime, and provide clients with efficient and reliable mechanical systems.

Conclusion

As the field of mechanical contracting continues to evolve, it is crucial for professionals to stay abreast of the latest technological advancements and embrace the opportunities they offer. By harnessing the power of technology, mechanical contractors in Dallas and beyond can enhance their capabilities, deliver superior services, and contribute to the development of more efficient and sustainable buildings. Ultimately, the impact of technology on mechanical contracting will continue to shape the industry, paving the way for further innovation and growth.

No comments yet