In the realm of industrial machinery, the unassuming yet indispensable component known as the V-belt plays a pivotal role in ensuring smooth operations across various sectors. From manufacturing plants to automotive engines, V-belts silently transfer power, connecting motors to shafts and enabling the seamless functioning of equipment. Let's delve into the multifaceted world of V-belts, exploring their significance and the diverse applications they serve:

- Efficient Power Transmission: V-belts excel in transmitting power efficiently from one rotating shaft to another. Their design, featuring a trapezoidal cross-section and frictional engagement with pulleys, maximizes contact area, minimizing slippage and energy loss during operation.

- Versatility Across Industries: From heavy-duty industrial machinery to everyday household appliances, V-belts find application in a myriad of settings. They drive conveyor systems in warehouses, power HVAC systems in buildings, and propel lawn mower blades in suburban gardens, showcasing their versatility and adaptability.

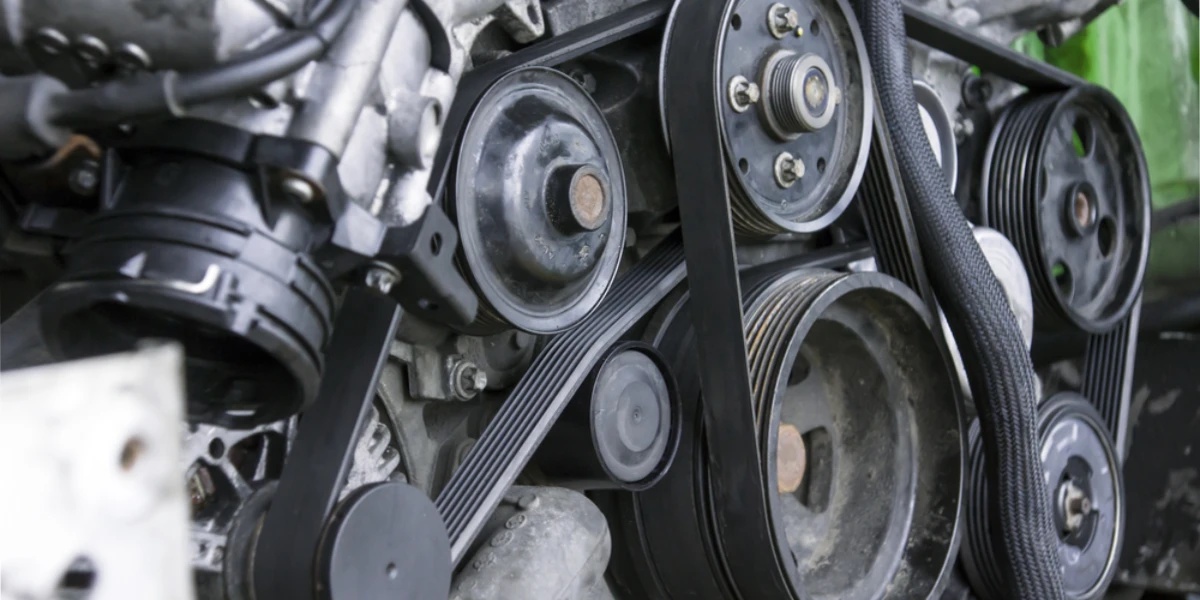

- Automotive Advancements: Underneath the hoods of automobiles, V-belts drive vital components such as alternators, water pumps, and air conditioning compressors. Their robust construction and reliable performance ensure the seamless operation of critical systems, contributing to the overall efficiency and longevity of vehicles.

- Agricultural Applications: In the agricultural sector, where machinery operates in demanding conditions, V-belts play a crucial role in powering equipment such as tractors, combines, and irrigation pumps. Their ability to withstand harsh environments and transmit power reliably makes them indispensable in modern farming practices.

- Maintenance and Replacement: Despite their durability, V-belts require periodic maintenance and replacement to ensure optimal performance. Factors such as wear and tear, tension loss, and exposure to contaminants necessitate regular inspections and timely replacements to prevent unexpected downtime and costly repairs.

- Technological Innovations: With advancements in materials science and manufacturing techniques, V-belts have undergone significant evolution. High-performance materials such as neoprene and polyester enhance durability and resistance to wear, while innovative designs cater to specific applications, further expanding the capabilities of V-belts in modern industries.

- Environmental Considerations: As industries increasingly prioritize sustainability and energy efficiency, V-belts have adapted to meet these evolving demands. Eco-friendly materials and lubricants reduce environmental impact, while advanced designs minimize energy consumption, aligning V-belts with sustainable manufacturing practices.

- Integration with Smart Technologies: In the era of Industry 4.0, V-belts are not immune to the wave of digital transformation sweeping across industries. Integration with IoT sensors and predictive maintenance algorithms enables real-time monitoring of belt condition and performance, facilitating proactive maintenance and optimizing operational efficiency.

- Educational Resources and Training: Recognizing the importance of proper installation and maintenance, manufacturers and industry associations offer educational resources and training programs on V-belt best practices. Equipping maintenance personnel with the knowledge and skills to handle V-belts ensures safe and efficient operation, minimizing downtime and maximizing productivity.

- Future Prospects: As industries continue to evolve and embrace new technologies, the role of V-belts remains vital in powering the machinery that drives progress. Whether in traditional manufacturing or emerging sectors such as renewable energy and electric vehicles, the versatility and reliability of V-belts ensure they will continue to be a cornerstone of industrial infrastructure for years to come.

In conclusion, while often overlooked, V-belts form the backbone of modern industrial machinery, enabling the efficient transfer of power across a wide range of applications. From automotive engines to agricultural equipment, their versatility, durability, and reliability make them indispensable components in countless industries. As technology advances and sustainability becomes paramount, V-belts will continue to adapt and thrive, serving as a symbol of innovation and progress in the industrial landscape.

No comments yet