Introduction

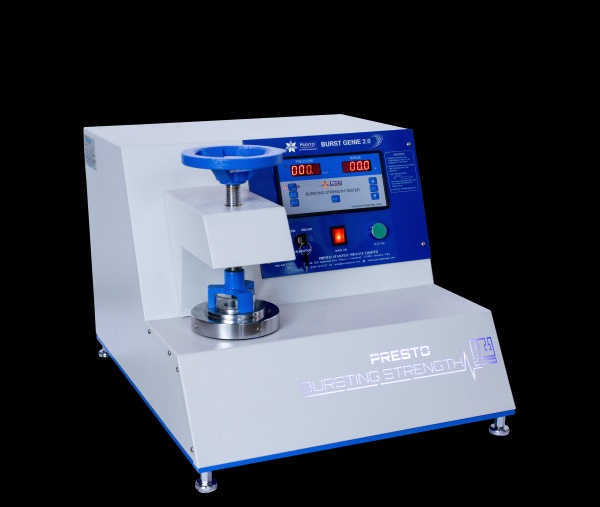

In the realm of material testing, the bursting strength tester manufacturer stands as a crucial tool, offering invaluable insights into the durability and resilience of various materials. Whether you are in the manufacturing industry or quality control, understanding the basics of a bursting strength tester, its principles, and the factors influencing its price is essential for making informed decisions. Let's delve into the world of bursting strength testers and explore why they are a cornerstone in material testing.

Bursting Strength Tester: An Overview

Manufacturers play a pivotal role in providing cutting-edge bursting strength testers that cater to diverse industry needs. One prominent name in the industry is [Manufacturer's Name], renowned for their commitment to quality and precision. When selecting a bursting strength tester, it's crucial to choose a reputable manufacturer with a proven track record in delivering reliable testing equipment.

Factors Influencing Bursting Strength Tester Prices:

The price of a bursting strength tester Prices can vary based on several factors, including:

-

Capacity and Range:

- Higher capacity and broader testing ranges often come with a higher price tag. Consider your specific testing needs to determine the appropriate capacity for your applications.

-

Automation and Features:

- Advanced features, such as automated testing procedures and data analysis capabilities, can contribute to increased prices. Evaluate your requirements and budget to find the right balance between features and cost.

-

Build Quality and Durability:

- The construction of the tester, including the materials used and build quality, can impact its price. Investing in a durable and robust machine may initially cost more but pays off in the long run through reliability and longevity.

-

Brand Reputation:

- Established brands with a history of delivering accurate and reliable testing equipment may have higher price points. However, the assurance of quality and precision can justify the investment.

Bursting Strength Tester Principle

The bursting strength tester Principle operates on a simple yet effective principle known as the Mullen Burst Test. This test assesses the ability of a material to withstand bursting forces exerted by a hydraulic or pneumatic mechanism. The basic steps include:

-

Specimen Preparation:

- A sample of the material is carefully cut and clamped between the annular clamps of the testing apparatus.

-

Application of Pressure:

- Hydraulic or pneumatic pressure is gradually applied to the specimen until it bursts. The pressure at which the material fails is recorded.

-

Analysis of Results:

- The bursting strength is measured in pounds per square inch (psi) or kilopascals (kPa), providing a quantitative assessment of the material's strength.

Conclusion:

In conclusion, the bursting strength tester is an indispensable tool for industries relying on the durability and quality of materials. When considering a purchase, carefully assess your testing needs, budget constraints, and the reputation of the manufacturer to make an informed decision. A well-chosen bursting strength tester ensures that your materials meet the required standards, contributing to the overall success and reliability of your products in the market.

No comments yet