The Snapmaker Multi-Material 3D Printer is revolutionizing the world of 3D printing by offering users the ability to print with a wide range of materials in a single print job. This remarkable capability opens up a world of creative possibilities, enabling users to unleash their imagination and bring their designs to life with unprecedented versatility. In this article, we will explore the power of multi-material printing on the Snapmaker and how it contributes to the fastness of Snapmaker 3D printers.

- The Versatility of Multi-Material Printing

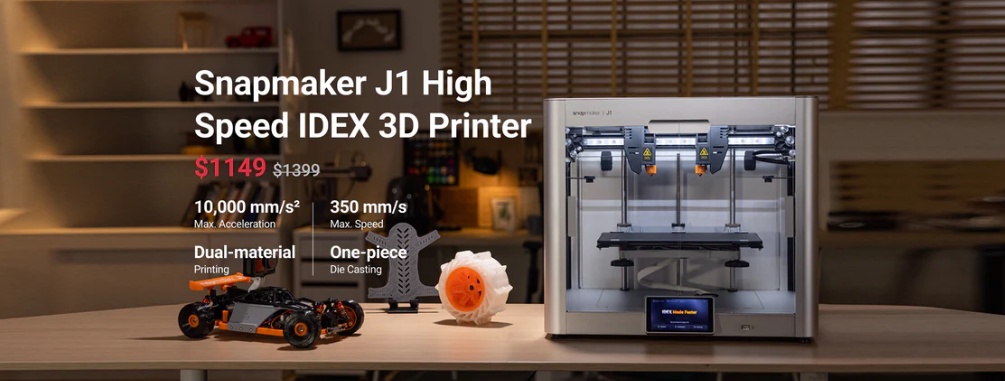

One of the key advantages of the Snapmaker Multi-Material 3D Printer is its ability to work with various materials such as PLA, ABS, TPU, and more. This versatility allows users to choose the material that best suits their specific application or project requirements. Whether it's creating functional prototypes, intricate models, or customized products, the ability to use multiple materials in a single print significantly enhances the scope of what can be achieved.

- Fastness through Simultaneous Printing

The ability to print with multiple materials simultaneously is a key factor in the Snapmaker fast 3D printers. With the Snapmaker Multi-Material 3D Printer, users can load different filaments into the respective extruders and print multiple parts of a design simultaneously. This eliminates the need for multiple print runs or manual material switching, resulting in considerable time savings and increased efficiency.

- Efficiency in Complex Designs

Multi-material printing also contributes to the fastness of Snapmaker 3D printers when it comes to complex designs. In intricate models or designs with intricate support structures, the use of different materials can greatly simplify the printing process. For example, using dissolvable support materials alongside the main printing material allows for easier and faster removal of supports, saving time and effort.

Combining Strength and Aesthetics

Another aspect where multi-material printing accelerates the printing process is the ability to combine different materials to achieve a balance between strength and aesthetics. By utilizing materials with specific properties, such as combining rigid and flexible filaments, users can optimize the structural integrity of their prints while maintaining the desired visual appearance. This eliminates the need for additional post-processing steps or assembling multiple parts, thereby speeding up the overall printing process.

Accelerating Iterative Design

With the Snapmaker Multi-Material 3D Printer, designers and creators can rapidly iterate their designs, enabling faster product development cycles. The ability to test different materials or material combinations in a single print run allows for quicker evaluation of design iterations, leading to faster refinement and optimization of the final product.

Visit here: https://www.youtube.com/watch?v=ztwqHWLtrNY

No comments yet