The concept of Air shower cleanroom has a new meaning because of the latest technology. A clean room is an artificial environment to contain airborne contaminants, microbes, aerosol particles, and chemicals. Such a technology finds many applications in manufacturing, medical care, and military requirements. Most high-tech products require cleanroom technology, which has opened many avenues for Cleanroom Equipment Suppliers in India.

We couldn't have made incredible achievements in electronics and medicine without the Air Washer unit and Cleanroom. One thing is obvious that the future of this industry is very bright. The use of Cleanrooms is now wider than just domestic applications because modern technologies have revolutionized the business of Cleanroom equipment suppliers. Industries like medical devices, biotech pharma, semiconductors, food processing, and packaging can only function with an air shower Cleanroom.

What is cleanroom technology?

Cleanroom technology involves controlling the environment of a room through artificial measures to prevent contamination from pollutants such as dust, microbes, airborne particles, chemicals, and water. Technology helps you control a Cleanroom's temperature, pressure, humidity, and other environmental parameters. It has created many business opportunities for Cleanroom Equipment suppliers in India, and now they are much sought after in areas like pharmaceuticals, medical treatments, biologics, food packaging, and semiconductors.

What are the benefits of an air shower in a clean room?

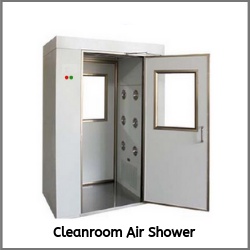

The air shower Cleanroom is an antechamber that acts as an entryway for Cleanrooms to reduce particle contamination. It produces high-pressure filtered air to remove dust particles, fibrous lint, and other pollutants. An air shower Cleanroom aims to keep your products safe and free from contamination. In the last few years, air shower manufacturers in India have received a lot of orders from domestic and overseas markets.

Leading cleanroom equipment suppliers and manufacturers in India

1. LuxMed

There are several options for those looking for a high-end stainless steel clean room equipment supplier. LuxMed is one of the leading Cleanroom Equipment suppliers. They are a one-stop solution provider for all your Cleanroom types of equipment, furniture, and pressure vessel requirements.

2. AART Thinking Global

AART thinking Global is another top manufacturer that provides turnkey solutions to different market segments. They are among the most reliable suppliers using the latest global technology to serve domestic and international projects.

3. Syntec Airflow System

Syntec Airflow System is one of the fastest-emerging Cleanroom Equipment suppliers. They have a team of well-trained professionals using the latest technology to manufacture many products, including Modular Operation Theater (OT) and Clear Room Puff Partition.

Besides these top manufacturers, there are many other good suppliers of Cleanroom types of equipment in India.

Cleanroom Equipment Manufacturers have a bright future

After introducing GMP systems across major industries, like pharma, electronics, lens manufacturing, critical machinery assembly area, food processing, and many other sectors, Cleanroom equipment manufacturers are getting a lot of business in the country. It's a win-win situation for the Indian economy and suppliers because it has created many opportunities for international developments in this field.

Cleanroom Equipment Manufacturers know the large business potential and are trying to emulate and update the latest technology. This industry has achieved phenomenal growth in the last two decades because of GMP Technical Solutions. It will only increase because many pharma/biotech /healthcare and electronics industries will need this technology.

However, domestic manufacturers are shifting their attention towards manufacturing critical equipment such as containment systems providing nanogram level, aseptic isolators, and biosafety cabinets for BSL-3 & 4 applications. Shortly, there will likely be more opportunities for such equipment in domestic and international markets. India is in the ideal position because local manufacturers can produce high-quality equipment at competitive prices. These factors can help India to increase its market share by following global quality standards.

India is in a very good position because many domestic players have recently started manufacturing Cleanroom equipment. The increased availability of skilled personnel, design, and construction expertise helped them. All these factors have made construction costs very competitive, giving an edge to Cleanroom equipment suppliers in India.

However, much work still needs to be accomplished for critical containment technologies and isolators because there is a huge scope for improvement in the quality of components and craft. Eventually, better R&D efforts will help achieve the industry's global ambitions.

New Challenges for the Cleanroom equipment industry

Currently, the Cleanroom equipment business looks very bright, but some problems persist because of the need for uniform specifications for the product. There are a lot of variations in the specifications given for Cleanroom products by different consultants and architects.

Compared to international suppliers, domestic Cleanroom equipment manufacturers are very competitive, but the additional excise duty and local taxes remove that advantage, especially against Chinese products. Indian government should look into this issue immediately because Cleanroom equipment suppliers will ultimately have to pay the price.

Read our blogs on TechPlanet !!

No comments yet