The aspect of chainflex Chainflex robot cables includes a vast range of information when one wants to be aware of the same. Therefore, it is essential to look through a well-constructed, comprehensive briefing about them, including all their performance features, applications, and considerations. Our post offers you a comprehensive guide to the Chainflex robot cables, including all the necessary information. So, let us begin the discussion without any ado!

What are the features of the Chainflex robot cables?

The following are the features of the chainflex robot cables:

Impeccable flexibility

The chainflex cables offer impeccable flexibility, which is possible because of their structure to ensure consistent flexing and bending. This makes them ideal for applications where conventional cables are not successful.

Resistant to abrasion

The cables usually feature outer jackets, which are resistant to abrasion. They can withstand wear and tear caused by rubbing, movements, and contact with other surfaces.

Longevity

The chainflex cables are optimally durable because their structure supports a long service life, irrespective of when the applications are dynamic and demanding. They can undergo extensive testing to guarantee optical cable durability in robotics.

What are the applications of the Chaiflex robot cables?

The following are their applications.

Robotics

The most evident area of their application is robotics. They are commonly used in robotic applications because there is a constant need for flexing and finding, including end-of-arm tooling, robots, and other automated systems.

Machine tools

For the CNC machines and their machine tools, which include fanfic moments, the chainflex cables can readily offer a suitable solution for signal and power transmission.

Material handling systems

The cables are ideal for use in conveyor systems and other material handling equipment where flexibility and reliability are necessary.

Packing machinery

Chainflex cables guarantee consistent operation and reduce the risk of cable failures in placing lines, which involves moving components.

What are the different considerations for chainflex cables?

The following are their considerations:

Dynamic testing

Searching for cables that have passed extensive dynamic testing is essential to guarantee their reliability and performance in real-world applications.

Supplier reputation

Looking for suppliers who have earned themselves a commendable reputation, are reliable, and offer a better guarantee of providing the best quality products and services. Therefore, it is best to opt for suppliers with a commendable reputation for their products and services.

Customisation

Some manufacturers provide options for customising the cables according to their applications' specific needs and requirements. Therefore, the effectiveness of the cables in functioning increases optimally.

Final Words

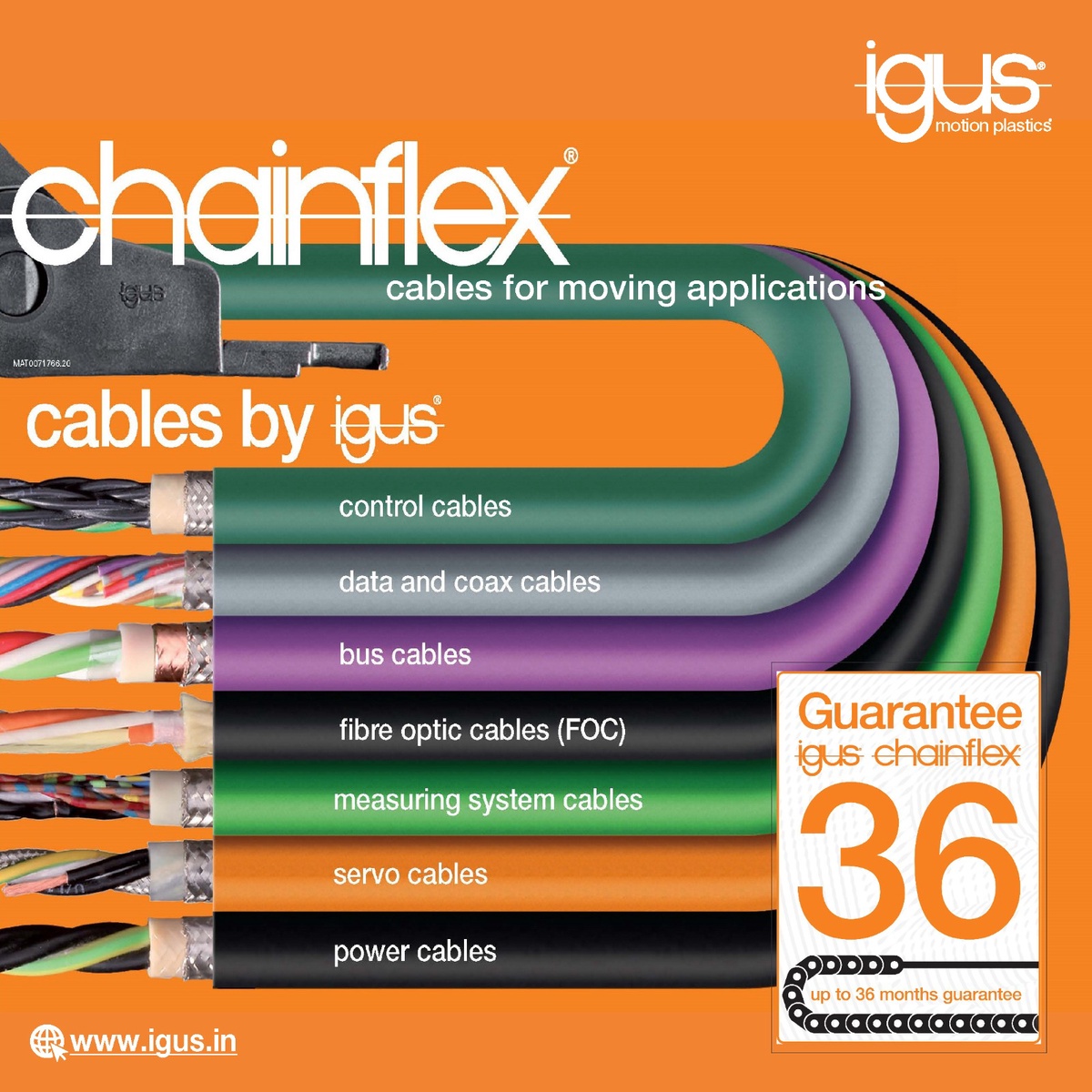

If you are looking for the best robotic cable management solutions and services, Igus Motion Plastics is the best company to resort to without any hesitation. It has gained the reputation of being one of the most reliable and proficient companies in offering the best services in this field. You also have the guarantee of getting the finest quality and the most affordable solutions and services when you opt for Igus Motion Plastics.

No comments yet