Whether you’re a small or midsize business, it’s critical to find inventory optimization software that works for you. The right tools can help you better manage demand, minimize your logistics costs, and avoid common inventory issues like stockouts, backorders, and overstocking.

For example, a solution that can predict customer demand accurately can be invaluable in avoiding restocking and inventory losses. It can also help you make adjustments to accommodate delays and unexpected demand on the fly.

Scalability

Inventory optimization software can help businesses increase flexibility and scalability, making it easier to adapt to changes in demand and supply, as well as growth and expansion. This can improve efficiency and profitability, enabling them to stay competitive in a dynamic market.

Scalability is the ability of a system to handle increased demands in terms of storage, processing, and data volumes without causing performance problems. This is a crucial capability in any IT system, including applications and databases.

A scalable system can increase capacity in response to new needs without having to perform a rearchitecting or refactoring process, which can lead to additional costs, risks, and complexity. This is why it is important for any enterprise to consider scalability when choosing hardware and software solutions.

Integrations

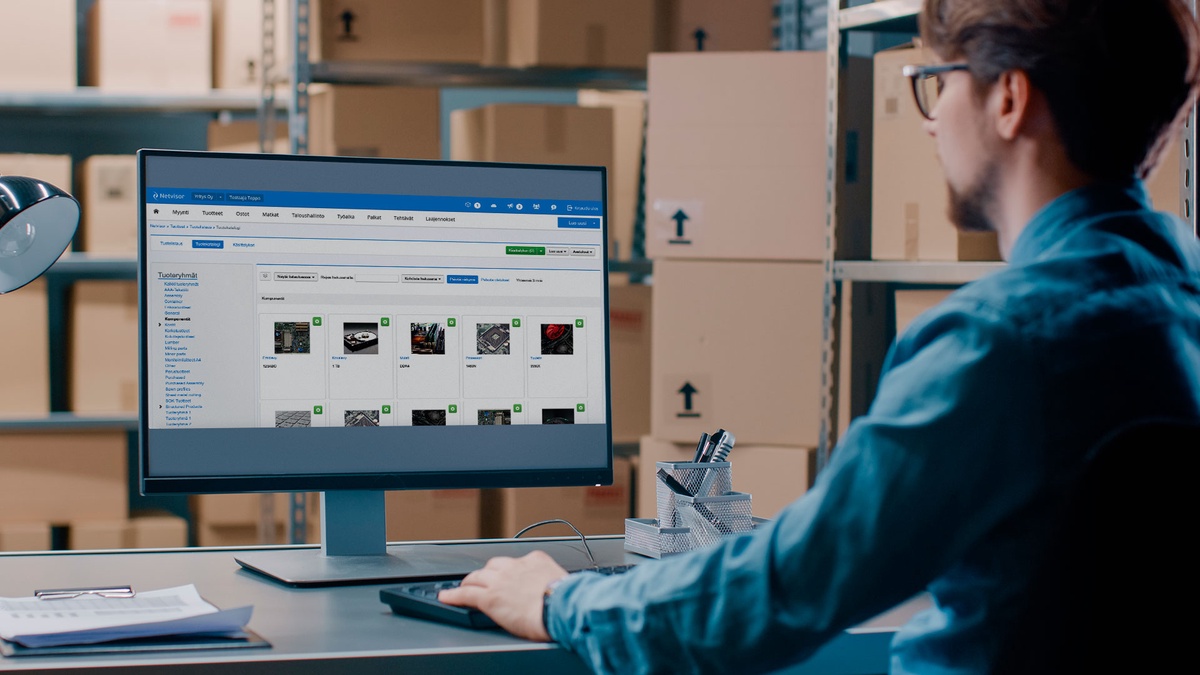

One of the best things about inventory optimization software is the ability to integrate with a wide range of other business applications. This can save your business time and money, and improve efficiency by ensuring that all aspects of your business are in sync with each other.

For example, inventory optimization systems can be integrated with accounting tools to ensure that financial reports are accurate and consistent. This can save your business time and money, as well as ensure that you’re keeping a close eye on cash flow and profitability.

Another advantage of integration is that it helps your supply chain stay efficient and avoid stock-outs and overstocking. A shortage or overstock of inventory is costly and can lead to lost sales opportunities or customer dissatisfaction.

Inventory optimization software can also help your business optimize warehouse layouts and increase production efficiencies. This is especially important for large-scale warehouses. It can also help you determine what materials your warehouse needs to support production and reorder when necessary.

Reporting

Inventory optimization software should be able to offer a variety of reporting capabilities. These include a view of your entire supply chain, as well as reports that allow you to monitor your performance against specific goals and objectives.

A robust reporting system can help you make informed decisions about reordering, shipping and purchasing. It also helps you keep track of your progress and avoid costly mistakes.

Moreover, you should look for inventory optimization software that integrates with other systems, such as point-of-sale (POS) and accounting software. This enables you to have a complete, 360-degree view of your inventory and a comprehensive understanding of your business.

Smart technologies enable you to leverage a variety of data sources, including past demand forecasting and customer behavior, which is crucial for successful inventory optimization. This enables you to balance stocking levels and order based on your most profitable products. This results in reduced inventory investment, improved customer satisfaction and cost containment.

Analytics

Inventory optimization software can help you balance supply and demand to avoid stockouts and high storage costs. The software uses predictive analytics to forecast product demand and project inventory levels.

It also makes it easier to calculate reorder points, and automates reordering activities. This can save time and money while ensuring customers get the product they need as soon as possible.

The software can also help you track your inventory throughout the supply chain using barcodes and RFID. You can create checkpoints that scan your inventory to provide real-time data on inventory levels.

The ability to track your inventory across multiple locations is critical to delivering a fast and consistent experience to customers. The right tech-enabled inventory allocation strategy can make a difference to your shipping strategy and your profit margins.

No comments yet