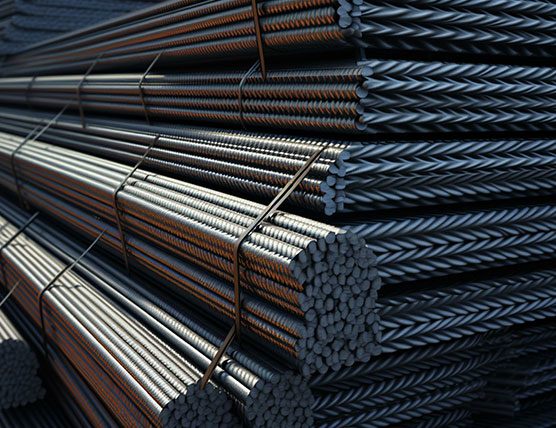

In the constantly evolving landscape of construction, the importance of dependable and durable building materials couldn't possibly be more significant. Among these materials, Thermo-Precisely Treated (TMT) bars have arisen as a cornerstone of modern construction projects, offering a large number of advantages over conventional reinforcement materials. From towering high rises to critical infrastructure, TMT bars have revolutionized the manner in which we fabricate, ensuring underlying integrity, resilience, and safety. This article investigates the evolution, properties, and applications of TMT bars, highlighting their indispensable role in shaping the constructed climate.

Evolution of TMT Bars:

The evolution of TMT bars is well established in the journey for stronger, more tough building materials. Historically, construction depended on traditional reinforcement materials, for example, Mild Steel Bars (MS Bars), which had inherent restrictions concerning strength, ductility, and corrosion resistance. Be that as it may, with progressions in metallurgical engineering and manufacturing processes, TMT technology arose as a leading edge innovation during the twentieth hundred years.

TMT bars go through a progression of controlled processes including quenching, tempering, and thermo-mechanical treatment, which confer better mechanical properties than the bars. This includes higher rigidity, further developed ductility, upgraded weldability, and predominant corrosion resistance. These progressions shot TMT bars to the very front of modern construction, offering a compelling answer for the difficulties presented by ordinary reinforcement materials.

Properties and Advantages of TMT Bars:

TMT bars have an exceptional combination of properties that make them indispensable in construction projects:

High Strength: TMT bars show essentially higher elasticity contrasted with ordinary reinforcement materials, enabling them to withstand weighty burdens and underlying anxieties.

Ductility: The thermo-mechanical treatment process gives phenomenal ductility to TMT bars, allowing them to twist without compromising their primary integrity. This property is especially pivotal in tremor inclined districts where structures need to withstand dynamic powers.

Corrosion Resistance: TMT bars are engineered to oppose corrosion, ensuring long haul durability and minimal maintenance necessities. This is fundamental for structures presented to cruel ecological circumstances or destructive components.

Weldability: TMT bars can be handily welded without compromising their strength or ductility, facilitating productive construction processes and enabling the formation of perplexing primary designs.

Fire Resistance: TMT bars have a higher melting point contrasted with traditional reinforcement materials, enhancing their fire resistance and ensuring primary integrity in the event of fire incidents.

Cost-Effectiveness: Regardless of their unrivaled properties, TMT bars offer cost-viable solutions for construction projects, considering their lengthy lifespan, decreased maintenance requirements, and generally durability.

Applications and Impact in Construction:

The flexibility and dependability of TMT bars have prompted their far and wide reception across different construction applications:

High-Rise Buildings: TMT bars structure the primary backbone of high-rise buildings, providing the fundamental strength and flexibility to withstand vertical and horizontal burdens.

Infrastructure Projects: TMT bars are integral components in the construction of bridges, flyovers, tunnels, dams, and other critical infrastructure projects where underlying integrity is fundamental.

Residential and Business Construction: From individual houses to business edifices, TMT bars assume an essential part in ensuring the primary stability and safety of buildings.

Industrial Structures: Industrial offices like factories, stockrooms, and power plants depend on TMT bars for their strength and durability in demanding conditions.

The impact of TMT bars stretches out a long way past their nearby applications, influencing the general quality, safety, and sustainability of construction projects. By enhancing underlying integrity, minimizing maintenance prerequisites, and improving resilience against cataclysmic events, TMT bars contribute essentially to the lifespan and unwavering quality of infrastructure worldwide.

Future Perspectives:

Looking forward, the future of TMT bars in construction is ready with conceivable outcomes. Innovations in material science, manufacturing cycles, and sustainability initiatives are ready to further improve the exhibition and natural certifications of TMT bars. These include progressions in nano-technology integration, development of smart TMT bars with implanted sensors for primary wellbeing monitoring, reception of eco-friendly creation practices, and investigation of advanced coatings and surface treatments for further developed corrosion resistance.

As the construction industry continues to advance, TMT bars will remain at the bleeding edge of innovation, reinforcing the structures we fabricate and shaping the future of modern construction. With their unrivaled strength, durability, and sustainability, TMT bars stand as a demonstration of human ingenuity and engineering greatness, ensuring that the buildings and infrastructure of tomorrow are totally solid.

In conclusion, TMT bars have arisen as the cornerstone of modern construction, offering a vigorous and dependable answer for the difficulties of underlying reinforcement. As we embrace the chances of a quickly changing world, TMT bars will continue to assume an urgent part in shaping the fabricated climate and advancing the principles of safety, resilience, and sustainability in construction rehearses worldwide.

No comments yet