Different extruders function in a similar fashion. The filament is first fed into the extruder, where a motor and gears propel it toward the hot end. Within the hot end, electrical heating, typically through resistance, melts the filament. Finally, the molten material is precisely extruded through a nozzle and deposited layer by layer onto the heated bed, ultimately forming the desired three-dimensional object.

Most printers only have one extruder, while some have two. So, which is better — single or dual? Depending on your budget, two is always better than one for the most part. In fact, the dual extruder printer have become more and more common in recent years and are even trending to replace single-head printers.

What are the features that define the best dual extruder 3D printer? What is the functional difference between single and dual extrusion? With a better cooling capacity, the dual extrusion 3D printing module under single-nozzle mode performs better than the single extrusion 3D printing module when printing slopes and overhangs. In addition, a dual extruder can print objects using two different filament colors or types on the same print. This allows you to create more complex and colorful projects. Using a dual extruder printer lets you set different parameters for each extruder directly in the slicer software and complete dual material printing in one print job. Please note that two-color printing is not impossible with a single extruder, and it can be achieved by manually changing the filament.

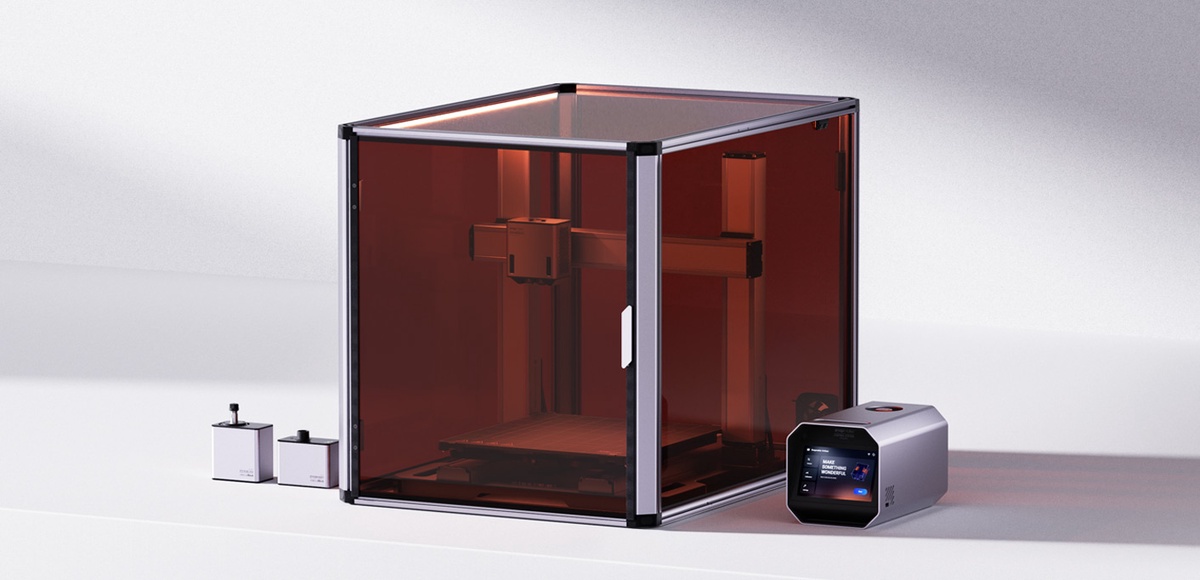

When shopping for Snapmaker 3D printer models, it is important to note that dual extrusion technologies will differ depending on the model. As such, the dual extrusion 3D printing module for an artisan 3D printer differs from that of the Snapmaker 2.0 dual extrusion 3D printing module.

When it comes to calibration, the Snapmaker 2.0 dual extruder applies a proximity sensor to detect the distance between the heated bed and the nozzles. On the other hand, the Snapmaker artisan dual extruder can function without a proximity sensor. It detects the leveling stats of the heated bed by touching the build plate using its left nozzles.

While the Snapmaker 2.0 dual extrusion 3D printing module boasts both proximity and optoelectronic switches, the latter is solely utilized for Z offset calibration. Implementing the optoelectronic switch for mesh bed leveling would introduce slight warping of the platform upon nozzle contact, ultimately compromising the accuracy of the process. Consequently, glass plates are only compatible with the Snapmaker 2.0 when using manual leveling.

Visit here: https://www.youtube.com/watch?v=9XJ5m6flx_E&t=58s

No comments yet