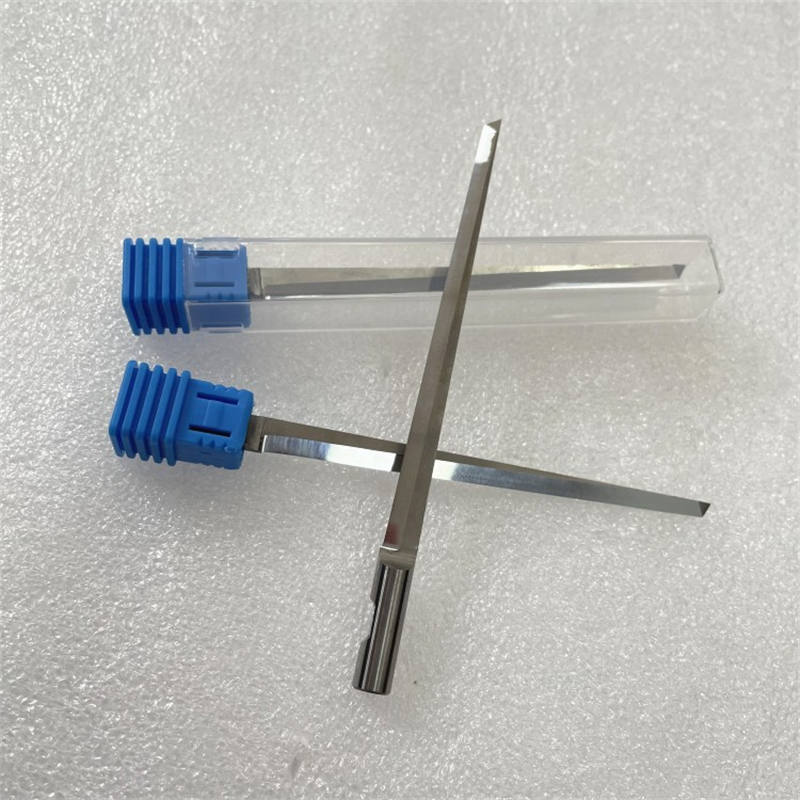

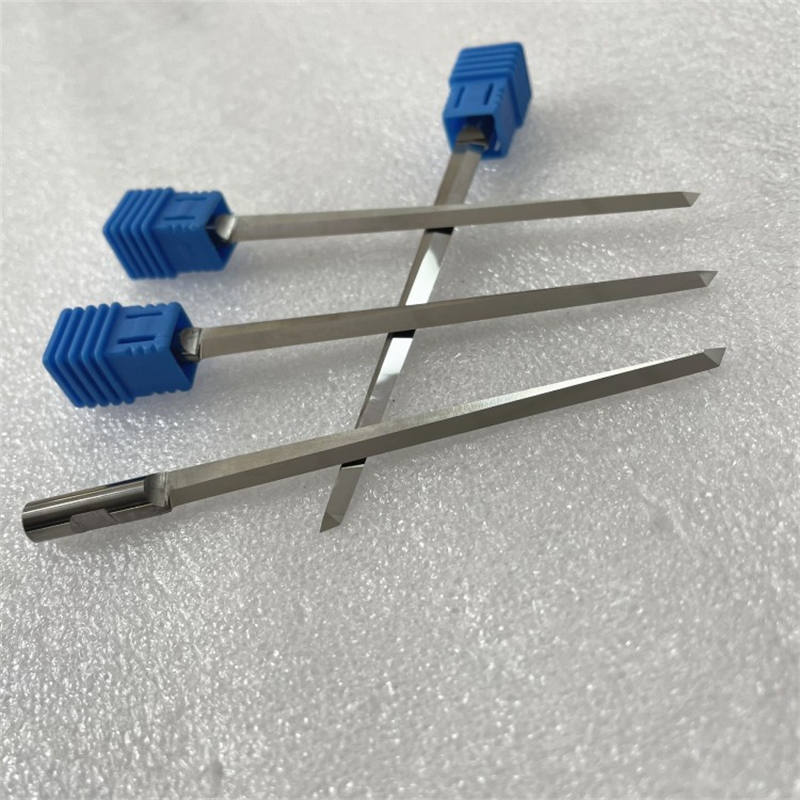

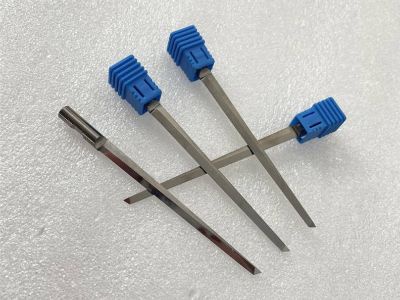

Tungsten Carbide Blade – A Cutting Edge Solution for Your Cutting Needs

As we all know, cutting is a manufacturing procedure important production. The quality for any cutting procedure plays a vital task the quality of the end product. To ensure a high-quality cutting, it's essential to use a cutting tool that was high-quality. That's where Tungsten Carbide Blade comes to the image., we will talk about the advantages, innovation, safety, use, and quality of Tungsten Carbide Blade and their applications in numerous industries.

Advantages of Tungsten Carbide Blade

Tungsten Carbide Blade is renowned for its high hardness and, which makes it very durable and long-lasting. It is one from the most difficult Tungsten Carbide Blade materials used for cutting, which enables it to withstand temperatures which may be extreme wear by continuous usage.

The blade's power and durability furthermore rendering it highly resistant to chipping and breaking, which means that it may maintain its sharpness for extended periods, decreasing the need for frequent sharpening.

Innovation in Tungsten Carbide Blade

The of Tungsten Carbide Blades has undergone significant innovation years that are recent. The use of new manufacturing techniques has enabled the creation of Tungsten Carbide Blades and better performance and accuracy.

One associated with the innovations is the growth of coatings that augment the blade's resistance to corrosion use and, enhancing the blade's lifespan. Furthermore, the use of computer-aided design and production (CAD/CAM) has enabled the creation of complex geometries, enabling the blades to accurately cut more.

Security of Tungsten Carbide Blade

Protection is just a crucial aspect of cutting process. Tungsten Carbide Blades are known to be safe due to their high resistance to and tear, which decrease the threat of blade breakage. Additionally they produce fewer sparks and dust compared to other cutting tools, decreasing the risk of fire and explosions.

Nonetheless, despite having Tungsten Carbide Blades, safety precautions require to be studied to prevent accidents. Operators must wear protective gear as gloves, goggles, and dirt masks to avoid exposing their epidermis and lungs to debris and dust.

Use and How to Use Tungsten Carbide Blade

Tungsten Carbide Blades can be found in different forms and sizes, making them well suited for various applications that are cutting. They may be used to cut hard and tough materials as metals, ceramics, plastics, and composites.

To use tungsten carbide Blade, a cutting are needed by you compatible tool with the blade's specification. Before using the blade, make sure that its securely fitted to the tool holder, and the product holder try securely placed into the cutting machine.

When cutting, make sure the blade is run during the true speed and the cutting process is adequately lubricated. This will make certain that the blade cuts through the material smoothly and produces a clean and cut that was accurate.

Service and Quality of Tungsten Carbide Blade

To maintain the blade's performance and longevity, it is crucial to service it regularly. Regular repair may help to identify any damage as use to the blade and rectify it before it affects the blade's performance. It is usually essential to keep the blade acceptably lubricated to prevent wear and tear.

The quality of Tungsten Carbide Blades varies, according to the maker and the manufacturing procedure used. It is important to purchase blades from reputable manufacturers who use top-quality garbage and the manufacturing latest techniques to produce blades of this highest quality.

Applications of Tungsten Carbide Blade

Tungsten Carbide Blades need numerous applications in several industries, including

1. Aerospace – used tungsten carbide blade to cut tough and abrasive materials as titanium and composites.

2. Automotive – used to cut metals, plastics, and more components used in vehicle production.

3. Medical – used in medical instruments and products.

4. Woodworking – used to cut hard and thick woods.

5. Paper and publishing – used to cut cardboard and papers.

No comments yet