Introduction to Belt Conveyors

Belt conveyors are ubiquitous material handling equipment used in various industries. They consist of a continuous loop of sturdy conveyor belts, typically made of rubber, fabric, or metal, which rotate around a series of pulleys. These conveyors are designed to transport goods or bulk materials from one location to another, allowing for efficient and reliable movement within factories, warehouses, mines, and other industrial settings.

Components and Operation of Belt Conveyors

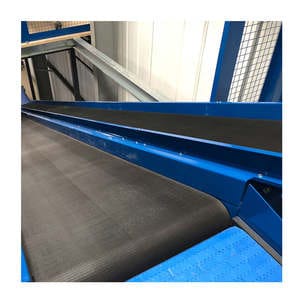

Conveyor Belt: The belt conveyor is the heart of the system. It consists of multiple layers of material carefully designed to withstand the demands of carrying heavy loads. The top layer, known as the cover, protects the belt from abrasion, impact, and other external factors. The belt's core provides strength and stability, while the bottom cover prevents moisture or debris from penetrating the belt.

Pulleys and Rollers: Belt conveyors rely on pulleys and rollers to support and guide the conveyor belt along its path. Drive pulleys are powered by electric motors or engines, providing the necessary force to move the belt. On the other hand, idler pulleys and rollers support the belt and maintain proper tension, ensuring smooth and consistent movement.

Belting Configurations: Belt conveyors can be configured differently depending on the specific application. Flat belts are commonly used for horizontal transportation, while troughed, belts are suitable for conveying bulk materials at an incline or in a trough-shaped configuration. Cleated belts have raised sections or cleats to prevent materials from sliding backward or falling off the belt.

Controls and Safety Features: Modern belt conveyors are equipped with advanced controls to regulate the speed and direction of the belt, allowing for precise and efficient material handling. Safety features such as emergency stops, pull cords, and sensors help to prevent accidents and ensure worker well-being. These features are essential for maintaining a safe working environment.

Advantages and Applications of Belt Conveyors

Advantages of Belt Conveyors: Belt conveyors offer several advantages over other forms of material handling equipment. They provide a continuous flow of goods, reducing manual handling and labor costs. Belt conveyors can handle various materials, from small and delicate items to heavy and bulky loads. They are highly versatile and can be customized to fit specific space and operational requirements. Additionally, belt conveyors are energy-efficient, contributing to sustainable operations.

Applications of Belt Conveyors: Belt conveyors find applications in diverse industries. In manufacturing, they facilitate the movement of raw materials, components, and finished products along assembly lines. Warehouses utilize belt conveyors for efficient storage and retrieval of goods. Mines rely on conveyors to transport extracted minerals and ores. Belt conveyors are also used in airports, seaports, and distribution centers for handling baggage and cargo. Their versatility makes them valuable in various industries, enhancing productivity and streamlining logistics.

Maintenance and Considerations for Belt Conveyor

Regular maintenance is crucial to ensure the longevity and performance of belt conveyors. This includes routine inspections, cleaning the conveyor belt and components, and promptly addressing any signs of wear or damage. Proper lubrication of pulleys and rollers is essential for smooth operation. Additionally, operators should be trained in the safe operation and maintenance of belt conveyors, promoting a culture of safety within the workplace.

Conclusion

Belt conveyors are an integral part of modern industries, offering efficient and reliable transportation of goods and materials. Understanding the components, operation, advantages, and maintenance considerations associated with belt conveyors enables businesses to optimize their material handling.

No comments yet