Permanent magnets and their assemblies play a pivotal role in countless applications, ranging from everyday consumer electronics to advanced industrial machinery. Understanding the science behind is crucial for harnessing the full potential of these magnets.

Permanent Magnets and Assemblies:

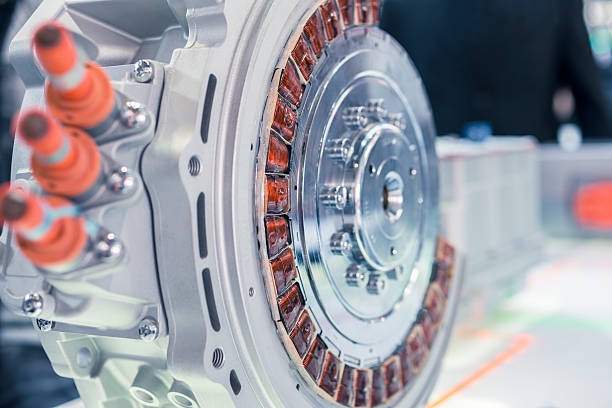

Permanent magnets are materials that retain their magnetic properties, creating a persistent magnetic field. Commonly used materials for permanent magnets include neodymium, samarium-cobalt, and ferrite. These magnets are integral components in various devices, such as electric motors, generators, and magnetic resonance imaging (MRI) machines.

Assemblies of permanent magnets involve combining multiple magnets to enhance their overall magnetic strength or achieve specific geometries for different applications. These assemblies are designed to meet the unique requirements of diverse industries, from automotive engineering to renewable energy.

Magnetization Process:

Magnetization is the process of aligning the magnetic domains within a material to create a unified and persistent magnetic field. There are different methods for magnetizing materials, each influencing the properties of the resulting magnet.

- Domain Alignment:

- At the microscopic level, magnetic materials consist of tiny regions called domains.

- During magnetization, an external magnetic field is applied to align these domains in a specific direction.

- This alignment contributes to the creation of a net magnetic moment, making the material a permanent magnet.

- Magnetic Hysteresis:

- The process involves a phenomenon known as hysteresis, where the magnetic properties of a material depend on its history of exposure to a magnetic field.

- As the external magnetic field is applied, increased magnetization occurs until saturation is reached. Upon removing the field, some residual remains.

- Coercivity and Remanence:

- Coercivity is the measure of a material's resistance to demagnetization.

- Remanence is the residual left in a material after the external magnetic field is removed.

- These characteristics are crucial for determining the performance of permanent magnets in specific applications.

MQI Technology:

In recent years, Magnetic Quantum Integration (MQI) technology has emerged as a game-changer in the field of permanent magnets. MQI leverages quantum mechanics principles to manipulate the magnetic properties of materials at the atomic level. This revolutionary technology enables precise control over magnetization, resulting in magnets with enhanced strength, stability, and efficiency.

The benefits of MQI technology include:

- Improved energy efficiency in magnetic devices.

- Enhanced magnetic performance, allowing for smaller and lighter designs.

- Greater control over magnetic properties, leading to customized solutions for various applications.

Permanent magnets and assemblies are indispensable in modern technology, driving innovation across industries. Understanding the process is essential for optimizing the performance of these magnets. As we look toward the future, the emergence of MQI technology promises to revolutionize the field, offering unprecedented control and efficiency in harnessing the power of magnets. The integration of MQI technology holds the key to unlocking new possibilities and pushing the boundaries of what permanent magnets can achieve in the ever-evolving landscape of technology and engineering.

No comments yet