Plastic injection molding is a versatile manufacturing process used in a wide range of industries, from automotive and aerospace to consumer goods and medical devices. It involves melting plastic pellets and injecting them into a mold, where they cool and solidify into a final product. In this article, we will explore the basics of plastic injection molding, including the process, materials, and applications.

China has become a leading player in the plastic injection molding industry, with many companies outsourcing their production needs to China injection molders. The cost advantages of working with China injection molders are well-known, as they can offer competitive pricing due to the country's lower labor and manufacturing costs. However, businesses must also be cautious when selecting a China injection molder to work with, as quality control issues have been reported in some cases. It is essential to work with a reputable China injection molder that prioritizes quality and offers reliable communication and customer service to ensure that the final products meet the desired specifications.

Introduction to Plastic Injection Molding

Plastic injection molding is a manufacturing process that has been around for over 150 years. It was first used in the production of billiard balls, and since then, it has evolved into a highly automated process used to produce a wide range of plastic products. The process involves melting plastic pellets and injecting them into a mold, where they cool and solidify into a final product.

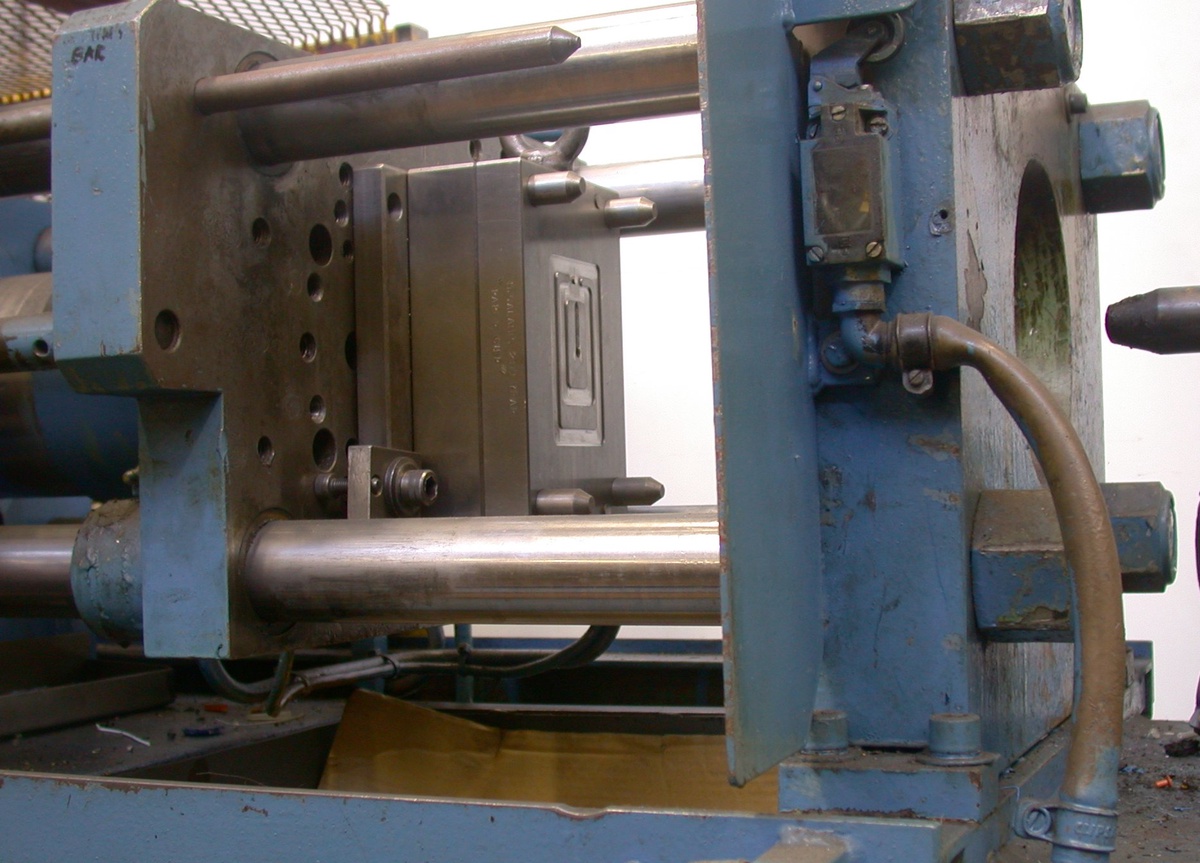

How Plastic Injection Molding Works

The plastic injection molding process involves several steps, including material preparation, mold preparation, injection, and ejection. The process begins with the melting of plastic pellets, which are then injected into a mold under high pressure. The plastic cools and solidifies in the mold, and the part is ejected from the mold.

Advantages of Plastic Injection Molding

Plastic injection molding has several advantages over other manufacturing processes, including high production rates, low labor costs, and the ability to produce complex geometries with tight tolerances. It also allows for the use of a wide range of plastic materials, including thermoplastics and thermosets.

Types of Plastics Used in Injection Molding

There are many types of plastics used in injection molding, each with its own unique properties and characteristics. Some of the most common types of plastics used in injection molding include polyethylene, polypropylene, polystyrene, and PVC.

The Injection Molding Process

The injection molding process consists of several stages, including material preparation, mold preparation, injection, and ejection. Each stage of the process is critical to ensuring the quality and consistency of the final product.

Design Considerations for Injection Molding

When designing a part for injection molding, there are several considerations to keep in mind, including draft angles, wall thickness, and gate location. These design considerations can have a significant impact on the final product's quality and manufacturability.

Common Defects in Injection Molding

Despite its many advantages, injection molding is not without its challenges. Common defects in injection molding include warping, sink marks, and flash. These defects can be addressed through proper mold design and process optimization.

Maintenance and Troubleshooting for Injection Molding

To ensure the longevity and reliability of injection molding equipment, proper maintenance and troubleshooting are essential. Regular maintenance can help prevent downtime and improve the quality and consistency of the final product.

Applications of Injection Molding

Injection molding is used in a wide range of industries and applications, from automotive and aerospace to consumer goods and medical devices. Some common products produced through injection molding include automotive parts, toys, medical devices, and household appliances.

Future of Injection Molding Technology

The future of injection molding technology is focused on improving efficiency, reducing waste, and increasing sustainability. Advancements in materials, automation, and process control are expected

No comments yet