Flow meters play a crucial role in various industries, providing the means to measure the rate of flow of a liquid or gas. Accurate flow measurement is essential for processes ranging from industrial manufacturing to environmental monitoring.

In this blog, we will delve into the world of flow meters, exploring their different types and applications and providing insights into the working principles and advantages of each.

Turbine Flow Meters

Turbine flow meters measure the rate of flow by utilising the rotational motion of a turbine within the flow stream. They have extensive applications in industries such as oil and gas, chemical processing, and water management. Turbine flow meters' advantages include high accuracy and the ability to handle a wide range of flow rates. However, their limitations may include susceptibility to wear in the presence of particulate matter in the fluid being measured.

Ultrasonic Flow Meters

Ultrasonic flow meters operate by measuring the time it takes for an ultrasonic pulse to travel between transducers. They are commonly used in industries such as wastewater treatment, pharmaceuticals, and food and beverage. Their nonintrusive installation and accurate measurement capabilities make them a popular choice. The benefits of ultrasonic flow meters extend to their ability to measure flow in large pipes without disrupting the flow.

Positive Displacement Flow Meters

Positive displacement flow meters operate by repeatedly filling and emptying a known volume chamber with the measured fluid. These meters are often used in custody transfer applications, batch processing, and hydraulic testing. Their advantages include high accuracy, even in viscous or non-Newtonian fluids, and the ability to measure low flow rates. However, they may be prone to damage if subjected to high flow rates beyond their design limits.

Magnetic Flow Meters

Magnetic flow meters, also known as magmeters, operate based on Faraday's law of electromagnetic induction. They are widely used in agriculture, utilities, and pulp & paper manufacturing industries. The benefits of magmeters include their suitability for measuring the flow of conductive fluids, low maintenance requirements due to the absence of moving parts in contact with the fluid, and the ability to handle abrasive or corrosive liquids.

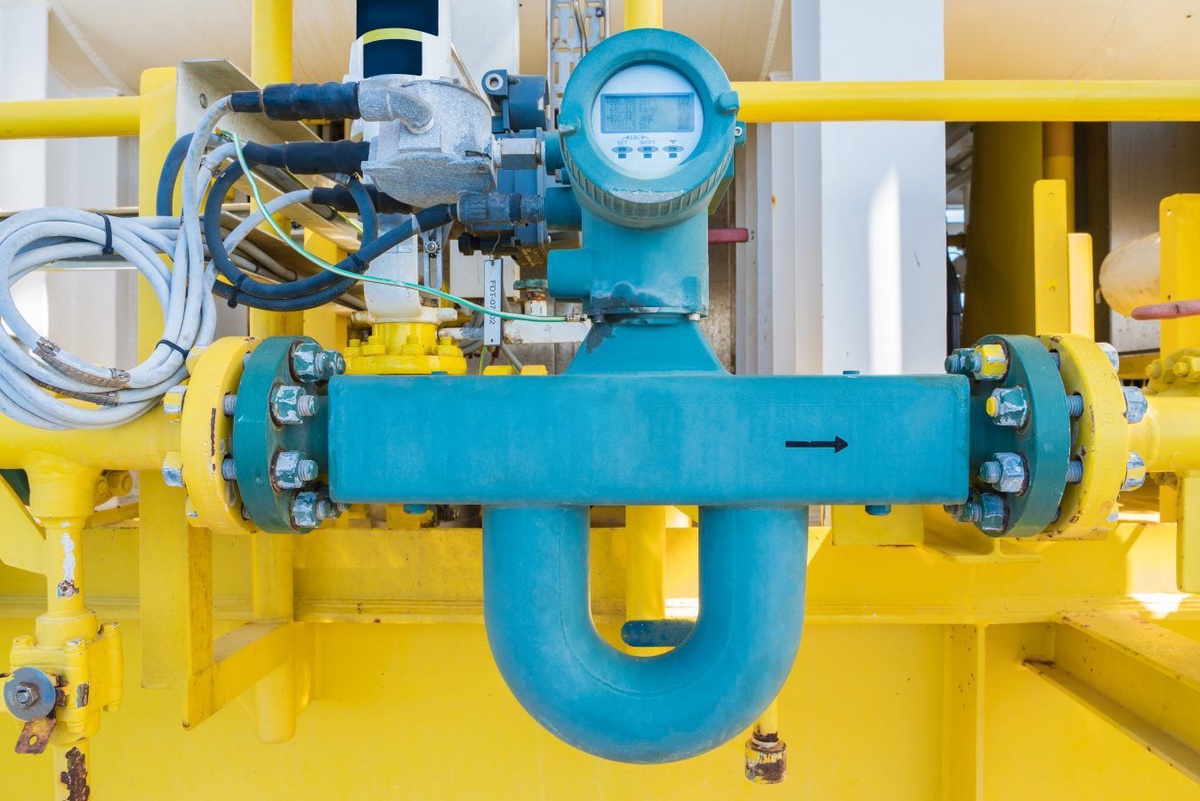

Coriolis Flow Meters

Coriolis flow meters utilise the Coriolis effect, which causes a vibrating tube to twist proportionally to the mass flow rate. These meters find applications in petrochemicals, refining, and food production industries. Their advantages lie in their ability to provide accurate measurements even with changing fluid properties, such as density, viscosity, and temperature. Additionally, they can measure flow in both directions, making them versatile for various applications.

Vortex Shedding Flow Meters

Vortex shedding flow meters measure the flow rate by detecting the vortices shed from a bluff body in the flow stream. They are commonly used in HVAC systems, power generation, and automotive applications. The benefits of vortex-shedding flow meters include their minimal maintenance requirements due to the absence of moving parts and their suitability for measuring the flow of steam, gases, and liquids with suspended solids.

Thermal Mass Flow Meters

Thermal mass flow meters measure heat dissipation from a heated sensor immersed in the flow stream. These meters are prevalent in environmental monitoring, air/gas blending, and semiconductor manufacturing applications. Their benefits include low-pressure drop, wide turndown ratio, and the ability to measure flow independent of the fluid's composition or density.

Comparative Analysis

A comprehensive comparison chart is provided to aid in decision-making, highlighting key differences among the various types of flow meters. This comparison encompasses cost-effectiveness, accuracy, and applicability to different fluids and flow rates.

Conclusion

In conclusion, the significance of choosing the right type of flow meter for specific industrial needs cannot be overstated. Each type of flow meter offers unique advantages and limitations, and selecting the most suitable one is crucial for ensuring accurate and reliable flow measurement. We encourage readers to seek professional advice to determine the most appropriate flow meter based on their requirements.

By exploring the various types of flow meters available on the market today, individuals and businesses can better understand which type is most suitable for their unique application, ultimately contributing to the efficiency and success of their operations.

No comments yet