Stainless steel bars are the most well-known material in numerous industries. They gain this much popularity due to their exceptional strength, formability, and corrosion resistance. Yet, its allure comes with challenges, particularly in welding. The heat conductivity and expansion coefficients of stainless steel demand careful consideration in choosing welding techniques and parameters. Thus, this guide equips you with the knowledge and strategies to tame SS welding wire, forging flawless and robust joints, fit for any industrial arena.

The Welding Colosseum: Key Players and Challenges

Several key players enter the welding process, each with a vital role:

- The Base Metal: Each grade of stainless steel possesses unique properties. Understanding the specific grade you're facing is crucial for choosing the right welding parameters and wire.

- The Welding Process: Picking the right welding process is essential. Popular choices include TIG, the precise and focused approach of a skilled swordsman; MIG, the rapid and automated tactics of a legionary; and SAW, the heavy-duty siege weaponry for the thickest materials.

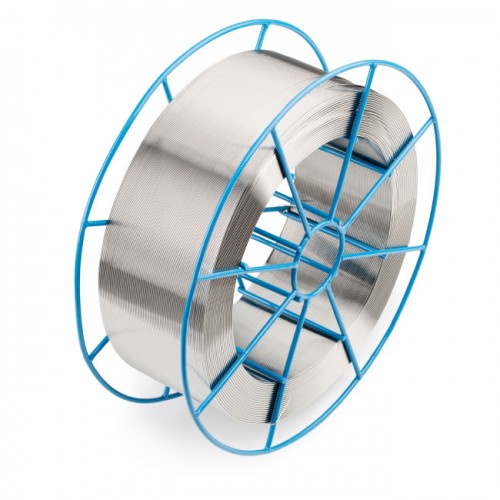

- The Welding Wire: This acts as a reinforcement, adding strength and resilience to the weld. Thus, choosing the right welding wire helps in ensuring compatibility and desired weld characteristics.

- The Welding Parameters: A stainless steel bar manufacturer always considers various parameters like current, vintage, shielding gas and travel speed to control the welding process properly.

Choosing The Ideal Welding Wire

- Matching Chemistry: The wire should be a close match to the base metal. It ensures the weld metal inherits the best traits (strength and corrosion resistance) from both parents.

- Ferrite Number (FN): This parameter represents the amount of ferrite present in the weld metal. Maintaining a sufficient FN helps in preventing cracks in thicker sections, akin to a strong shield protecting against enemy attacks.

- Corrosion Resistance: Leading stainless steel manufacturers choose a welding wire with superior corrosion-fighting abilities for exceptional resistance to harsh environments.

Optimizing the Parameters: Refining the Forge

After choosing the right welding wire, it's time to optimize the performance. Voltage, current, travel speed, arc length, and shielding gas composition converge in a symphony of parameters, each playing its part in shaping the weld. However, the best stainless steel bar manufacturer always considers these approaches:

- Consulting to WPS: Established Welding Procedure Specifications (WPS) serve as a guide, offering recommended parameters for specific combinations of base metal and welding wire.

- Test Weld: Conduct a test weld using the initial parameters. It allows manufacturers to inspect the weld for any weaknesses, like cracks or incomplete fusion.

- Adjusting Tactics: Based on inspection, manufacturers fine-tune their parameters. If the weld shows excessive penetration, it reduces the heat by lowering the current. Conversely, if it lacks fusion, it increases the heat with a slightly higher current.

- Practice Makes Perfect: they continue refining parameters through trial welds and evaluations until they achieve a high-quality SS welding wire.

Additional Consideration

Stainless steel welding wire manufacturers should also consider various additional considerations to ensure optimum results. Considering the thickness of the bars and the type of joint (butt, lap, etc.) influence the heat input and parameter selection. Thicker sections require more heat, achieved by adjusting parameters or preheating. Ensure that the welding surface is clean and free from contaminants. It would be best to adopt post-welding maintenance to remove further oxidation from the material.

In Conclusion

By following these strategies, an individual can transform from a novice to a champion welder, capable of forging unyielding bonds in the fiery heart of the welding colosseum. Remember, with the right knowledge, practice, and choosing the leading stainless steel manufacturers, Aamor Inox, you too can unleash the fury and tame the challenges of stainless steel welding.

No comments yet