Hydraulic pumps play a crucial role in powering a wide array of machinery and equipment across various industries. From construction and manufacturing to automotive and agriculture, the functionality of hydraulic pumps is indispensable.

In this blog, we aim to delve into the intricate workings of hydraulic pumps Australia, shedding light on their operation, applications, maintenance, and troubleshooting.

Hydraulic Pumps

Hydraulic pumps are mechanical devices that convert mechanical power into hydraulic energy. They are comprised of basic components such as a reservoir, hydraulic fluid, a pump, and a motor or engine to drive the pump.

The principle behind their operation is based on Pascal's law, which states that when pressure is applied to a confined fluid, the pressure is transmitted undiminished in all directions. This principle allows hydraulic pumps to transfer energy from one point to another with minimal loss.

Hydraulic pumps come in various types, including gear, vane, and piston pumps, each with its own unique features. Gear pumps, for example, are known for their simplicity and reliability, while vane pumps offer high efficiency and low noise levels.

Piston pumps, on the other hand, provide high power density and precision control. Understanding the different types allows for the selection of the most suitable pump for specific applications.

How Hydraulic Pumps Work

The working mechanism of hydraulic pumps Australia involves a series of phases, including suction, compression, and discharge. During the suction phase, the pump draws in hydraulic fluid from the reservoir. In the compression phase, the fluid is pressurised as it is displaced by the pump.

Finally, in the discharge phase, the pressurised fluid is delivered to the system, enabling the operation of hydraulic actuators or motors.

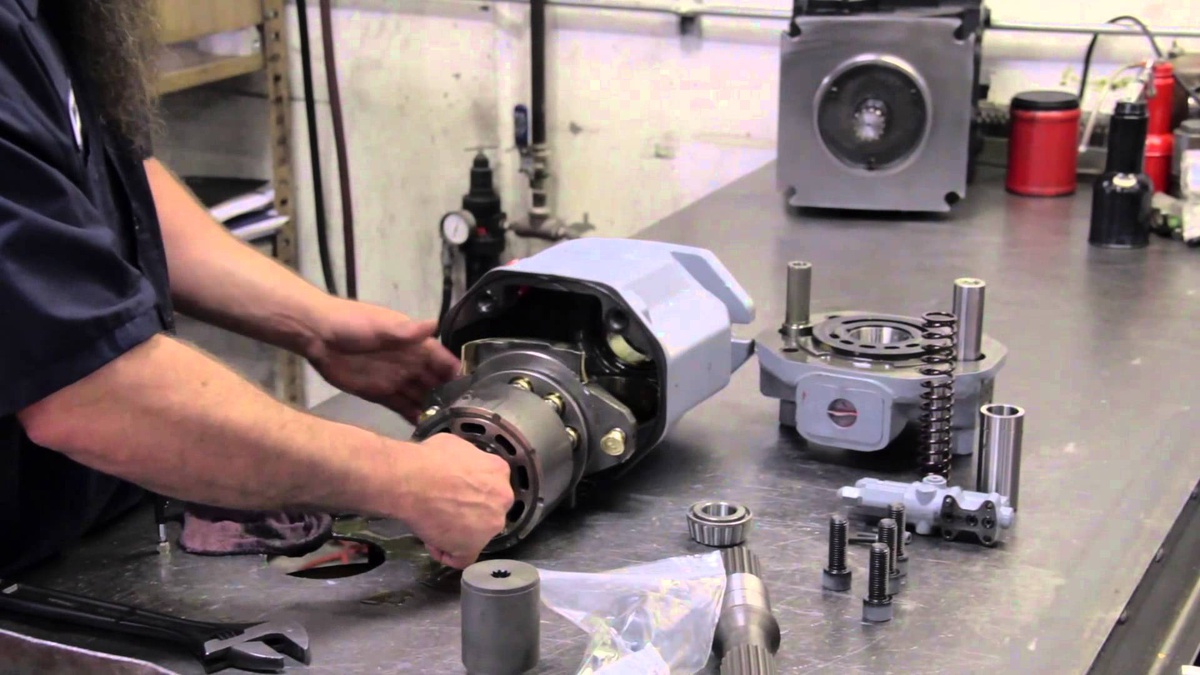

To enhance understanding, illustrative examples or diagrams can be utilized to visually depict the working process of hydraulic pumps. These visual aids provide clarity and insight into the inner workings, making it easier for individuals to grasp the intricacies of hydraulic pump operation. The efficiency and power output of hydraulic pumps are also emphasised, showcasing their ability to deliver high performance in diverse applications.

Applications Across Industries

Hydraulic pumps find extensive applications across various industries, contributing to the functionality of heavy machinery, precision equipment, and complex systems.

In the construction industry, hydraulic pumps power cranes, excavators, and forklifts, enabling the lifting and movement of heavy loads with precision and control. In manufacturing, hydraulic pumps drive presses, injection moulding machines, and other equipment, providing the force necessary for shaping and forming materials.

The automotive industry benefits from the use of hydraulic pumps in power steering systems, transmission systems, and braking systems. This enhances vehicle performance and safety. Moreover, the agricultural sector relies on hydraulic pumps to operate tractors, combine harvesters, and irrigation systems, facilitating efficient and productive farming practices.

Real-world examples further highlight the significance of hydraulic pumps in enabling essential processes and operations across diverse industries.

Maintenance and Troubleshooting Tips

Regular maintenance is essential to prolong the lifespan and ensure the optimal performance of hydraulic pumps.

This includes practices such as checking fluid levels, inspecting for leaks, and replacing filters and seals as needed. Additionally, understanding common issues that may arise, such as fluid contamination or pump inefficiency, is crucial for troubleshooting effectively.

Troubleshooting techniques can involve identifying the root cause of issues, whether it be through visual inspections or diagnostic testing. It's important to address issues promptly to prevent further damage and maintain the reliability of hydraulic systems.

Recommended resources or professional services can provide valuable support for maintenance and repairs, ensuring that hydraulic pumps continue to operate at their best.

Conclusion

The functionality and versatility of hydraulic pumps Australia make them integral components in a wide range of industries. Their ability to provide precise control, high force output, and reliability is unmatched, contributing to enhanced productivity and efficiency.

We encourage readers to explore further applications and consider implementing hydraulic systems in their operations to experience the benefits firsthand.

Source: Unleashing Power Exploring the Functionality of Hydraulic Pumps

No comments yet