Introduction:

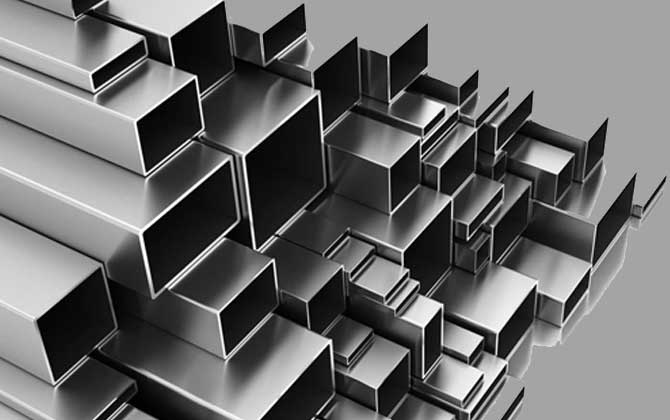

Mild Steel (MS) squares, often perceived for their structural stability and flexibility, assume a significant part in different enterprises, offering a scope of applications in construction, manufacturing, and design. In this article, we will dive into the characteristics, manufacturing processes, and the multi-layered applications of MS squares, revealing insight into their importance as key parts in present day engineering.

Characteristics of MS Squares:

MS squares display a remarkable arrangement of characteristics that add to their prominence and boundless applications. These characteristics settle on them a favored decision in different ventures:

- Structural Stability:

MS squares are prestigious for their structural stability, giving a robust framework to construction and engineering applications. Their capacity to withstand weighty loads and tension makes them ideal for supporting structures, platforms, and frameworks.

- Machinability:

MS squares offer phenomenal machinability, taking into consideration exact cutting and forming. This quality is especially worthwhile in manufacturing processes where precision and customization are fundamental, like in the production of machinery and equipment.

- Weldability:

Like other mild steel items, MS squares brag great weldability. This property works with the consistent combination of squares into different structural gatherings, giving strength and attachment to the general framework.

- Corrosion Resistance:

While MS squares might be powerless to corrosion over the long run, defensive coatings and medicines can be applied to upgrade their resistance to rust. This component makes them reasonable for both indoor and outdoor applications.

Manufacturing Process:

The manufacturing process of MS squares includes a progression of moves toward transforming raw materials into the eventual outcome. The key stages include:

- Raw Material Selection:

The production of MS squares begins with the selection of top notch raw materials, basically iron ore. The iron is then processed through refining to make steel, which fills in as the establishment for manufacturing MS squares.

- Billeting:

The underlying steel is formed into billets, which are long, square or rectangular bars. These billets are then warmed to high temperatures to improve their malleability for ensuing processing.

- Rolling:

The warmed billets are gone through a progression of rolling plants to lessen their size and shape them into square cross-segments continuously. The rolling process grants the ideal aspects and mechanical properties to the MS squares.

- Cutting and Finishing:

When the rolling process is finished, the MS squares are cut into explicit lengths in view of the planned application. The last step includes finishing, which might incorporate medicines for corrosion resistance of coatings for tasteful purposes.

Applications of MS Squares:

The versatility of MS squares makes them vital in various applications across various ventures. A few remarkable applications include:

- Construction and Building Structures:

MS squares track down far and wide use in the construction industry for making sturdy frameworks, supporting columns, and reinforcing structures. Their structural stability and capacity to withstand weighty burdens make them an essential part in the construction of buildings, bridges, and other infrastructure.

- Manufacturing of Machinery and Equipment:

The machinability and weldability of MS squares make them ideal for the manufacture of machinery and equipment. They act as structural parts, edges, and support structures in different manufacturing processes.

- Furniture and Interior Design:

MS squares add to the design and construction of furniture and interior structures. Their spotless lines, strength, and versatility go with them a famous decision for making present day and sturdy furniture pieces.

- Fencing and Security Applications:

The robust idea of MS squares makes them reasonable for fencing and security applications. Whether utilized in doors, hindrances, or security walls, MS squares give a dependable and sturdy arrangement.

Conclusion:

Mild Steel squares stand as flexible and fundamental parts in present day engineering and construction. From giving structural stability to offering customization in manufacturing processes, MS squares have demonstrated their strength across a range of applications. As ventures keep on advancing, the demand for MS squares is supposed to continue, displaying their versatility and persevering through importance in the unique landscape of materials engineering. Whether supporting transcending structures or adding to the style of interior design, MS squares stay a cornerstone in the underpinning of different ventures.

No comments yet