Have actually you ever wondered just what the capacity that is largest of PVC pelletizing machine is? PVC pelletizing machines are used to turn PVC raw materials into small pellets that can be used to create a variety of products. , we will explore the advantages, innovation, safety, usage, and quality of PVC machines which can be pelletizing.

Benefits:

Considered one of the biggest top features of PVC pelletizing equipment machines is they can create small, uniform pellets that can be used in a range that is wide of. These pellets can be used to produce products such as for example pipes, cable insulation, packaging movies, and window frames. The machines are extremely efficient, permitting manufacturers to produce large examples of PVC pellets quickly and effortlessly.

Innovation:

There are numerous innovations in PVC pelletizing machinesthe past several years. A majority of these innovations consist of the utilization of computerized controls that enable manufacturers to control the temperature precisely and pressure of the machine. This helps to guarantee that the PVC pellets are of a constant quality, and reduces the danger of defects in the product this is certainly final.

Safety:

Safety is a concern that is key working with PVC plastic pelletizing machine manufacturers require to make certain that they follow all safety directions whenever using the machines, such as using clothing this is certainly protective making certain the machines are correctly maintained. It is also important to make sure that the machines are operated by trained experts who possess the abilities being necessary experience to make use of them safely.

Usage:

PVC pelletizing machines are used in a number of companies, including the manufacturing that is plastic, the packaging industry, and the construction industry. They are used to create products which can be used in everyday life, such as for example for example pipes and window frames. PVC pellets can additionally be used to produce products that have actually specialized applications, such as for example medical tubing and insulation this is certainly electrical.

How to use:

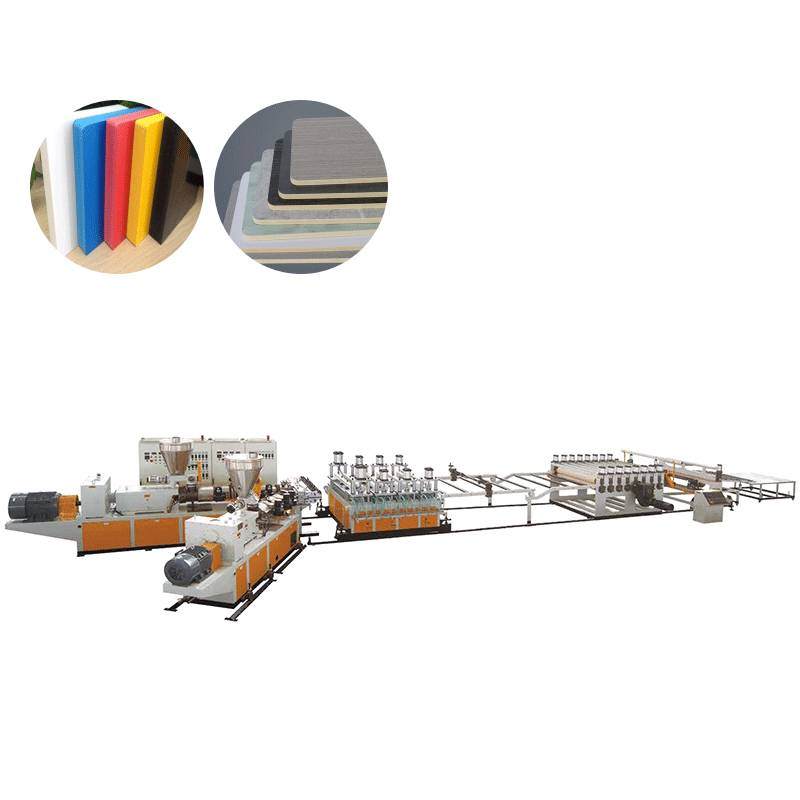

To use a PVC machine that is pelletizing manufacturers need to feed the raw PVC material into the machine. The material are going to be heated and compressed, which in turn causes it to melt and form pellets which can be small. The pellets are then gathered and cooled for use in the manufacturing process.

Service:

When purchasing a PVC machine that is pelletizing it is important to work with a manufacturer whom provides good customer service and support. This can add things such as tech support team, repair and maintenance services, and training for machine operators.

Quality:

The quality of the PVC pelletizing plastic developed by a machine this is certainly pelletizing a key consideration for manufacturers. High-quality pellets are crucial for creating products which can be safe, durable, and reliable. To make sure that the pellets are of a consistent quality, it really is important to work with a manufacturer whom utilizes the technology that is latest and equipment, and that is a rigorous quality control process in place.

Application:

PVC pelletizing machines are an tool this is certainly essential lots of industries. They enable manufacturers to create high-quality PVC pellets that can be used to make a range that is wide of. With innovations in technology and a focus on safety and quality, PVC pelletizing machines will remain to be an part this is certainly important of manufacturing process for years to come.

No comments yet