In logistics and supply chain management, warehouses play a crucial role. They are the central hub for storing, managing, and distributing goods to customers. With the upcoming e-commerce and online shopping, the demand for warehouses and the need for more efficient and effective warehouse operations has increased. One way to achieve this is through warehouse automation.

It involves using advanced technology and robotics to streamline operations and reduce manual labor. It can help businesses save time and money, increase efficiency, and improve accuracy.

Benefits of automation

- Increased Efficiency - Automation helps reduce the time needed to finish tasks, such as picking and packing. This, in turn, increases the overall efficiency of the warehouse.

- Improved Accuracy - Automation reduces the chances of errors and mistakes. Automated systems are more precise and consistent than humans, leading to fewer errors and returns.

- Reduced Labor Costs - Automated systems require less labor than manual processes, saving business costs.

- Better Inventory Management - Automated systems provide real-time inventory tracking and management, allowing businesses to optimize inventory levels.

- Enhanced Safety - Automation can reduce the risk of workplace accidents and injuries, making the warehouse a safer place for employees.

Types of automation

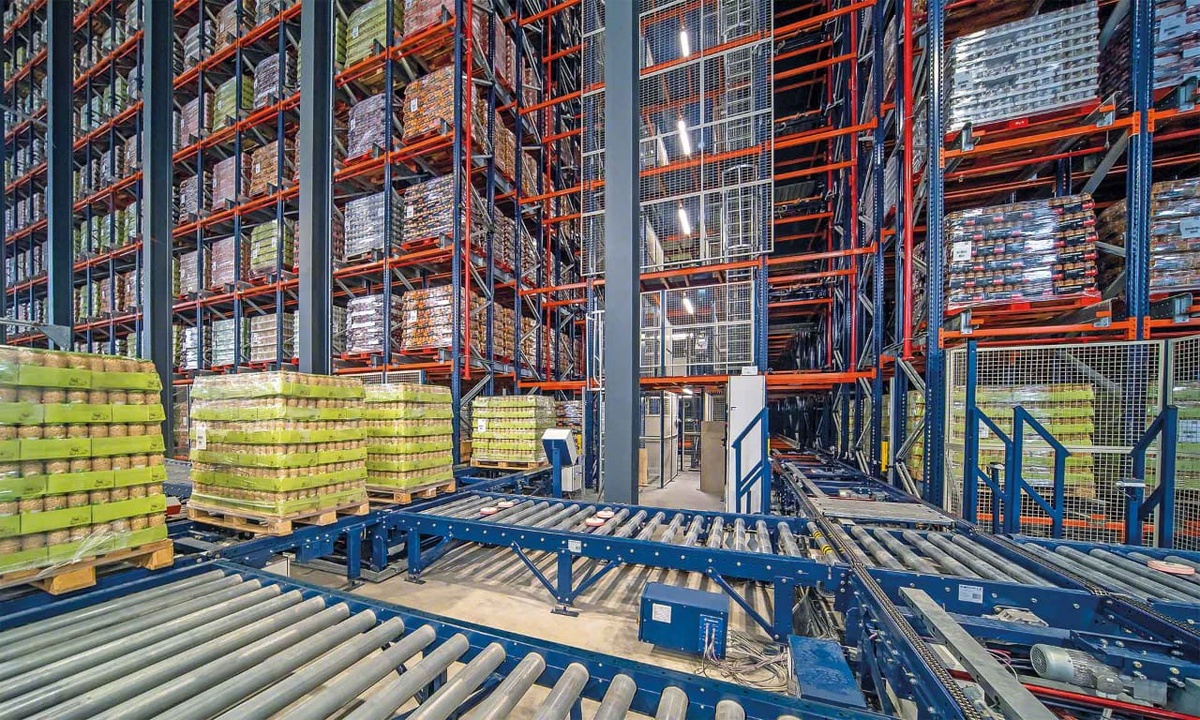

- Automated Storage and Retrieval Systems (AS/RS) - These are robotic systems that move products to and from storage locations within the warehouse.

- Conveyor Systems - Conveyor systems transport goods within the warehouse, reducing the need for manual labor.

- Automated Guided Vehicles (AGVs) - AGVs are autonomous vehicles that move products within the warehouse.

- Pick-to-Light Systems - Pick-to-light systems use light indicators to lead workers to the correct products and locations in the warehouse.

- Automated Picking and Packing Systems - Automated picking and packing systems use robotics and mechanical equipment to pick and pack products.

- Robotic Process Automation (RPA) - RPA involves using robots to automate repetitive tasks such as data entry and processing.

Challenges of automation

- High Upfront Costs – it can be expensive, with high upfront costs for equipment and installation.

- Integration with Legacy Systems - Integrating new automated systems with legacy systems can be challenging.

- Maintenance and Support - Automated systems require regular maintenance and support, which can add to the overall cost.

- Workforce Training - Automated systems require specialized employee training, which can take time and resources.

- Cybersecurity Risks - Automated systems can be vulnerable to cyber attacks, leading to potential data breaches and security risks.

Warehouse automation can help businesses improve efficiency, reduce costs, and enhance safety. By using advanced technology and robotics; warehouses can streamline operations and achieve better results. However, there are challenges, such as high upfront costs and cybersecurity risks. Despite these challenges, the benefits make it a worthy investment for businesses looking to stay competitive in the modern logistics and supply chain management world.

No comments yet