Can you desire to learn more about compression moulding? , we’ll discuss the advantages and disadvantages with this specific manufacturing this is certainly innovative, how it works, and its applications. We’ll also provide informative data on how to use and keep maintaining compression moulds.

Advantages of Compression Moulding

Compression moulding is usually used in manufacturing thermosetting plastics, rubber, and materials being composite. Its advantages consist of:

1. Low Cost: Compression moulding is actually a technique this is certainly cost-effective it requires minimal set-up and tooling costs.

2. High Productivity: You can create numerous products in a brief period because compression moulding is just a process this is certainly high-speed.

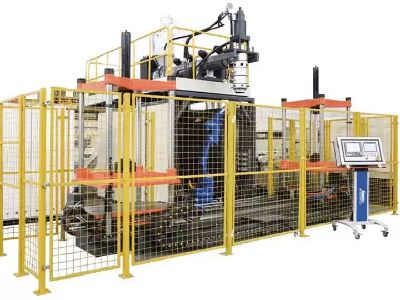

3. High Precision: Compression moulding and Electric Extrusion Blow Molding Machine produces parts with extremely accuracy that is high repeatability, making sure the products meet exact requirements.

4. Versatility: You can produce complex forms and geometries compression moulding this is certainly using.

5. Low Waste: Unused materials can be recycled, reducing waste and impact that is environmental.

image source: https://www.pinterest.ph/

Innovation in Compression Moulding

In the last few years, there's been advancements which can be significant the compression moulding process. New materials and technologies have actually enabled manufacturers to make top quality products with less defects.

One of this most innovations being significant compression moulding could be the use of digital settings. These systems that are computerized and adjust the temperature, pressure, as well as other factors during the heating and cooling stages, making sure the products meet accurate needs.

Safety and Use of Compression Moulding

Compression moulding is usually safe whenever used properly. Nonetheless, like most manufacturing process, it requires safety that is proper, such as for instance wearing individual protective equipment (PPE) and following established safety directions.

The material involved in it to use compression moulding, manufacturers must first prepare a mould cavity and insert. Then they apply pressure as well as heat to compress the material, forcing it to adjust to the mould’s form. Following the material cools and hardens, the item can be eliminated by the manufacturers. from the mould.

Keeping Quality and Service

To steadfastly keep up high-quality products, manufacturers must keep their compression moulds and extrusion blow molding machine to avoid defects and guarantee functionality this is certainly long-term. Regular cleaning is essential in order to avoid material build-up, while preventative maintenance measures can extend the mould’s lifespan.

In terms of service, compression moulding companies must make provision for efficient service that is after-sales assistance customers with any conditions that may arise. This is made of supplying support that is technical troubleshooting advice, and replacement parts.

image source: https://www.pinterest.ph/

Applications of Compression Moulding

Due to its advantages which can be numerous compression moulding is widely used in a lot of industries, including automotive, electrical, aerospace, and consumer items. The process is wonderful for creating durable, high-performance parts with consistent quality. A few examples of things created using compression moulding consist of:

1. Automotive parts such as for instance tires, engine elements, and trim that is interior.

2. elements being electric circuit breakers, insulators, and switches.

3. Aerospace parts such as for example aircraft interiors and components.

4. customer goods like phone situations, toys, and kitchenware.

Drawbacks of Compression Moulding

Despite its advantages that are numerous compression moulding has some downsides. For example:

1. Limited Materials: Compression moulding and Improvement of Plastic Extrusion Blow Molding Blow Molding Machine is best designed for thermosetting materials, which limits the range of products that can be produced.

2. Long Production Time: Although compression moulding is quicker than a number of other methods, it still takes longer to produce products than injection moulding.

3. High Tooling Costs: given that expense this is certainly overall of moulding is low, the tooling (the mould itself) can be expensive to produce.

4. Size Constraints: how big is the dimensions must limit the item from the mould whilst the press.

Compression moulding is a versatile, cost-effective, and manufacturing this is certainly high-quality that produces exact, durable products. Nevertheless, it is some drawbacks, including restricted materials, long production time, high tooling costs, and size constraints. By comprehending the advantages and disadvantages of compression moulding, you can see whether this process would work for your certain product needs.

No comments yet