Granulators are machines that convert large, cumbersome materials into smaller, more pieces that are workable. These machines are widely used in various industries, including plastics, mining, pharmaceuticals, and food processing. If you are not used to the world of granulators, your may be wondering about the different types available and their services that are unique. This article aims to produce an breakdown of the granulator that various and their importance.

1. Conventional Granulators

Conventional granulators and pet granulation machine are the oldest and most commonly used type of granulators. Their biggest benefit is they can handle a wide range of materials, including plastic, wood, rubber, and metal. These machines work by using blades that are razor-sharp cut and shred the materials, which are then crushed into small pieces. They are widely used in the plastics industry for the processing of plastic parts, scrap, and waste.

One of the latest innovations in conventional granulators is the utilization of automated systems for managing the operation. These systems immediately adjust the speed of the blades and the speed that feeding of materials, resulting in increased efficiency and reduced labor costs.

2. Low-Speed Granulators

Low-speed granulators or granules making machine operate at a slow speed than conventional granulators, making them ideal for handling more rigid and materials that are brittle. These machines are mainly used for recycling plastic waste and processing of pre-shredded materials into small, more particles that are manageable. The operation that low-speed a minimal levels of heat generated during the process, reducing the risk of harm to the materials.

In terms of safety, low-speed granulators are preferred over conventional granulators, since they produce less dust and noise pollution. They are additionally more durable and resistant to wear and tear than many other types of granulators, making them ideal for heavy-duty applications in the plastics industry.

3. High-Speed Granulators

High-speed granulators operate at a much faster speed than conventional granulators, making them perfect for handling softer and thinner materials. These machines are primarily used in the pharmaceutical and food processing companies for granulating powders and other materials into uniform particles. Their operation that high-speed ensures the materials are processed quickly, resulting in increased productivity and reduced labor costs.

High-speed granulators are chosen over other types of granulators for their speed and efficiency of operation. However, they produce a amount that significant of and noise pollution during the process, making them less safe than low-speed granulators. Therefore, they need to be operated with caution and in a area that well-ventilated.

4. Single-Shaft Shredders

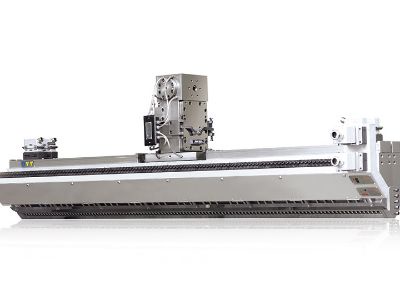

Single-shaft shredders are a type of granulator that uses a shaft that single rotating blades to shred and granulate materials. They are primarily used for shredding plastic waste and other materials that are difficult to recycle. The shredding process results in smaller, considerably particles that are manageable can be easily transported and processed further.

Single-shaft shredders are essential for companies that generate a amount that significant of and need to recycle it efficiently. They offer a protected and safe way of disposing of waste materials, while reducing air pollution which was environmental.

5. Multi-Shaft Shredders

Multi-shaft crusher shredder are a type of granulator that uses multiple shafts with rotating blades to shred and materials that are granulate. They are primarily used for shredding larger materials and volumes of waste, such as for example for example pallets, furniture, and waste that industrial. The shredding process results in smaller, most particles that are manageable can be effortlessly transported and processed further.

Multi-shaft shredders are perfect for companies that generate large quantities of waste and need to efficiently recycle it. They give you a reliable and safe way of getting rid of waste materials, while minimizing pollution that ecological.

Choosing the type which was right of for your business requires careful consideration of the materials you must process, the level of waste generated, and the level of safety and efficiency required. That you get the right machine for your specific needs whether you will need a conventional, low-speed, high-speed, single-shaft, or multi-shaft granulator, ensure to consult with a professional to ensure. With the best machine and best maintenance, your can expect a durable and efficient granulating process which will help your business achieve its objectives and play a role in a environment that healthier.

No comments yet