What's a Precision Surface Grinder and its Requirements?

You will need a precision surface grinder if you would like to generate exact and smooth flat surfaces on different materials. This device is essential in metalworking, plastic, and cup industry. The grinder shaves down the surface of the materials to completely make them flat and smooth. Nonetheless, to achieve precision grinding, you can find some demands that are strict the machine operator.

Advantages of Precision Surface Grinder Processing

Precision surface CNC Grinder Machine has advantages that are several. First, it will help manufacturers create flat areas having an precision of 0.0002 inches. This degree of precision may not be accomplished with other practices. 2nd, it grinds large amounts of product in a short number of time, reducing manufacturing costs. Lastly, the machine is durable and dependable, rendering it a investment that is vital machine shops.

Safety Requirements

The machine operator needs become trained on safety measures before utilizing a precision surface grinder. This includes wearing gear that is protective safety glasses, gloves, and earplugs. Machine operators also needs to know about the crisis stop button on the machine in the event of any problem through the procedure that is grinding.

Innovation in Precision Surface Grinding

Innovation in precision surface grinding has led to improvements in machinery design and increased functionality. Contemporary precision surface grinders include computerized numerical control (CNC) systems, which allow for precise control regarding the procedure that is grinding. The CNC system is additionally utilized to recall saved information regarding the procedure that is grinding future use.

Use and How to Use a Precision Surface Grinder

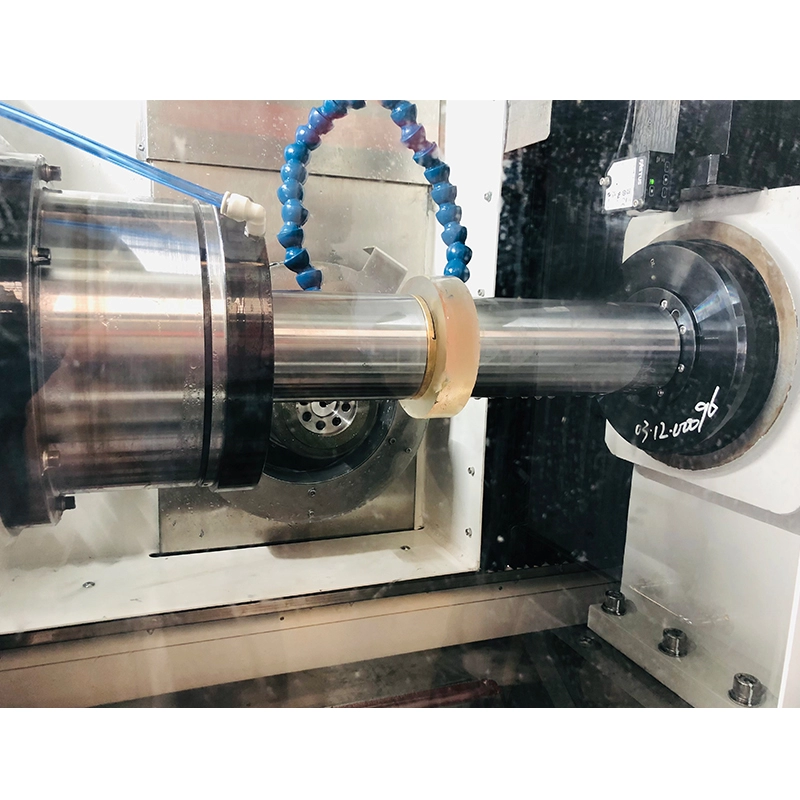

Using a precision Double Surface Grinding Machine starts with selecting the best wheel for the product ground that is being. The wheel should really be as hard as feasible and really should be dressed correctly to avoid damaging the product. The machine operator should adjust the rate then, feed rate, and depth of the cut. The product should really be clamped securely to your grinder to prevent it from moving during the process that is grinding.

Service Needs

To make certain performance that is optimal long life of the machine, regular upkeep and service is necessary. This consists of lubrication of moving components and checking the problem for the wheel that is grinding. The machine operator should additionally check for just about any uncommon noises or vibrations, which may indicate a problem that is technical.

Quality Control and Applications of Precision Surface Grinder

Quality control is crucial in the manufacturing industry, and High Precision Surface Grinder is not any exception. The parts produced by the grinder must meet standards that are strict specifications. Testing and assessment are performed usually to make certain quality.

Precision surface grinding discovers applications in different areas, including aerospace, automotive, and medical. The aerospace industry, for instance, uses precision surface grinding to produce aircraft components. In the market that is automotive precision surface grinding is utilized to create parts for engines and transmissions.

No comments yet