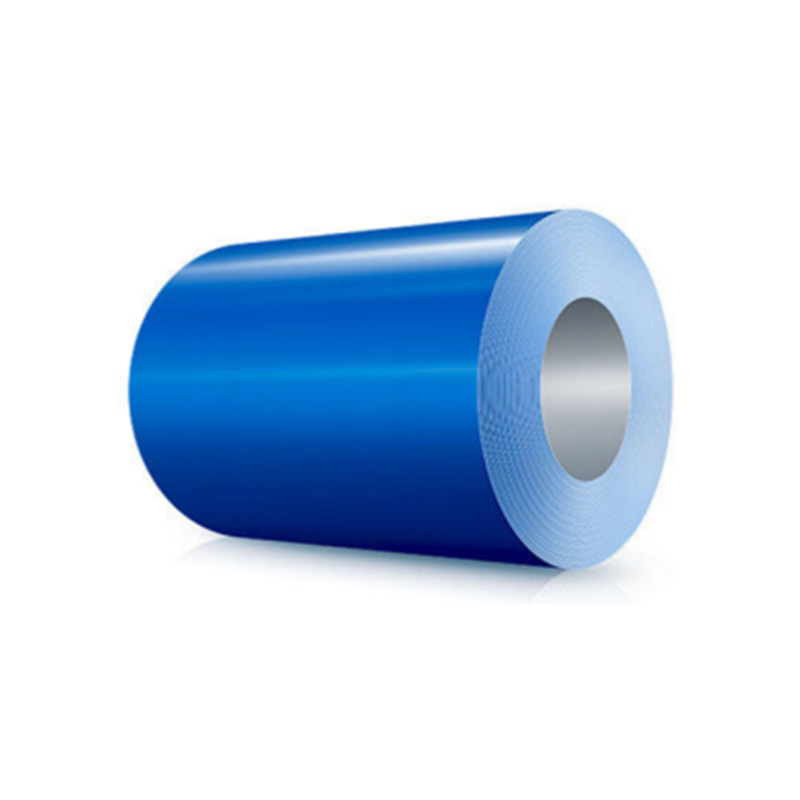

Have you been interested in learning colored aluminum coils? Then you 're on the right page if yes. Aluminum coils are generally used in the construction industry simply because they provide a lightweight and solution that durable to a lot of other materials. These coils are pre-painted in various colors and are used in structures, roofing, and tasks which can be architectural. This article that short you with all the provided information you should know about colored aluminum coils.

Types of Coatings:

You can find various types of coatings for colored carrier aluminum coils available in the market, including polyester, polyurethane, and PVDF. Polyester coatings are the many type that is typical of used in the construction industry. These coatings are affordable and offer a level that great of. Polyurethane coatings will be more high priced than polyester coatings but they are very resistant to abrasions, chemical compounds, and UV rays. PVDF coatings are the most durable and high-priced of all of the of the coatings. They feature exemplary opposition against diminishing, chalking, and color modification.

Advantages of Colored Aluminum Coils:

Colored aluminum coils provide a advantages that are few other materials used in construction. They are lightweight and quite simple to put in, which decreases the construction this is general and cost. Colored aluminum coils are really resistant to corrosion, weathering, and fire. In addition they mirror sunshine, making them suitable for areas with high conditions. Furthermore, colored aluminum coils come in a number of colors, afford them the ability for architects and builders to come up with vibrant and designs being appealing.

Innovation and Safety:

The development of brand technology that new enhanced the performance of colored aluminum coils, making them safer and better. The usage of advanced level coatings and manufacturing procedures has made aluminum this is colored more resistant to ecological facets such as for instance UV rays, rainfall, and wind. Innovative technologies have was able to ensure it is feasible to produce colored aluminum coils with improved fire-resistant properties, making sure they are typically safe to make use of in structures.

Utilizing Colored Aluminum Coils:

Colored aluminum coils are really very easy to make use of and can be cut to just about any size and shape to suit any project needs. The aluminum coils an be set up using different practices, including repairing that mechanical bonding, and snap-locking systems. Before installation, ensure the surface is clean, dry, and free from any oil, oil, or dust. Installation directions can vary for various manufacturers, so it's important to see the manufacturer's directions before using the coils.

Service and Quality:

The quality of colored aluminum coils is important, as it impacts the performance this is durability that general of material. Quality coils opposition that offer corrosion that exceptional UV rays, and weathering. They provide lasting protection for the building, which decreases the need for high priced maintenance. Manufacturers offer guarantee durations which range from 10-30 years, influenced by the type of layer used. It really is important to pick a manufacturer this is reliable a good reputation for creating high-quality colored aluminum coils.

Application of Colored Aluminum Coils:

Colored aluminum coils and prefinished aluminum coils are used in different applications in the construction industry. They have been used in roofing, cladding, fascias, and soffits, and others. They are an option this is very good architects and builders who want to produce unique and designs that are appealing. Colored aluminum coils may additionally be used in the transport industry for the label of vehicles and aeroplanes. They have been lightweight and non-corrosive, helping to cause them to an material that is ideal the transport sector.

Colored aluminum coils provide a few advantages over other materials used in construction. They're lightweight, durable, and come in a variety that wide of. The various types of coatings cater which can be located various applications and provide varying levels of durability. It is important to pick a manufacturer that reputable follow their instructions during installation to ensure the optimal performance of the colored aluminum coils.

No comments yet