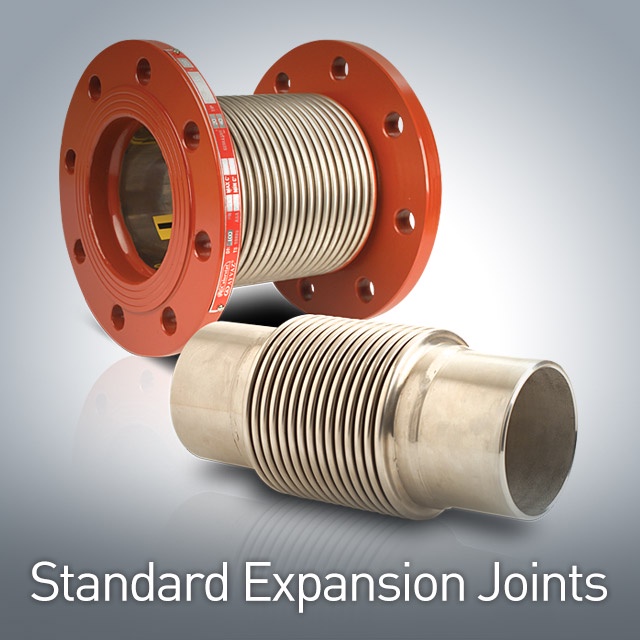

Expansion bellows, compensators, etc. are the common names used to describe highly useful expansion joints.

Choosing the right expansion joints means choosing from one or more metal bellows, rubber addition, or PTFE joints. Selecting metals can be a great idea for extreme temperatures but necessitates high-strength properties.

However, non-metallic expansion joints are designed to deliver the best results in terms of dimensional changes and ducts. Such issues can arise from heat-induced expansion, vibrations, pressure deformations, misalignment, etc.

Can expansion joint manufacturers make a difference?

Choosing the right expansion joints manufacturers is important as these products are designed by keeping in mind critical aspects like -

- Shape of convolution

- Series of convolution

- Withstanding high temperature

- Deliver flexible design

- Accommodation of movements in axial, lateral, or angular deflection, etc.

Why should you consider expansion joint manufacturers?

These factors are considered crucial components of the manufacturing process and are widely adopted by leading industries like pipe systems, etc.

These offer flexibility, and advantage, reduce stress and ultimately handle the pipe loads to sensitive equipment. When done right, this helps to prolong the overall life of the piping systems and control the instances of facing downtime.

What makes non-metallic expansion joints so important?

Selecting the right non-metallic expansion joints is designed to deliver and absorb thermal expansion and contraction. They are made of materials such as rubber, fabric, and plastic, which offer unique advantages over traditional metallic expansion joints.

The non-metallic expansion joints are designed to absorb movement in multiple directions, including axial, lateral, and angular, making them ideal for complex piping systems. Their flexibility also allows them to absorb vibration, reducing the stress on the piping and equipment.

Another advantage of non-metallic expansion joints is their resistance to corrosion and chemicals. Rubber and plastic materials are inherently resistant to chemicals and UV radiation, making them suitable for use in harsh environments. Additionally, non-metallic expansion joints are lighter in weight than their metallic counterparts, making them easier to handle and install.

- Rubber expansion joints are made of synthetic rubber and are suitable for high-temperature applications.

- Fabric expansion joints are made of woven materials, such as nylon or polyester, and are suitable for low-pressure applications.

- Plastic expansion joints are made of materials such as PVC or PTFE and are suitable for highly corrosive or high-temperature applications.

They are ideal for use in complex piping systems and harsh environments where traditional metal expansion joints may not be suitable.

Selecting the right type of non-metallic expansion joint for a specific application is essential for ensuring its effectiveness and reliability.

Applications of top-quality expansion joints

Expansion joints are used in a variety of applications across many industries to allow for the movement of materials, prevent damage to equipment and structures, and ensure safe and efficient operations.

Other benefits are -

- Piping systems:

In piping systems, expansion joints are used to absorb the movement caused by thermal expansion and contraction.

The expansion joint allows the pipe to move without causing stress on the surrounding equipment and structures. Such joints are also used to reduce the effects of vibration and shock caused by fluid flow.

- Building construction:

Expansion joints are used in building construction to allow for the movement of structures caused by temperature changes, seismic activity, wind, and other environmental factors. They are used in concrete slabs, walls, roofs, and other structural components to prevent cracking, buckling, and other types of damage.

- Bridges and highways:

Expansion joints are used in bridges and highways to allow for the expansion and contraction of concrete caused by temperature changes. They also absorb the movement caused by seismic activity and traffic loads.

- Aerospace industry:

Expansion joints are used in the aerospace industry to accommodate the thermal expansion and contraction of aircraft components, such as engine exhaust systems and fuel lines.

- Marine industry:

Expansion joints are used in the marine industry to accommodate the movement caused by wave motion, tides, and temperature changes. They are used in ship piping systems, cargo tanks, and other marine equipment.

Similarly, these are designed to accommodate the movement of air ducts caused by temperature changes and vibration. They also absorb the noise and vibration caused by airflow.

No comments yet