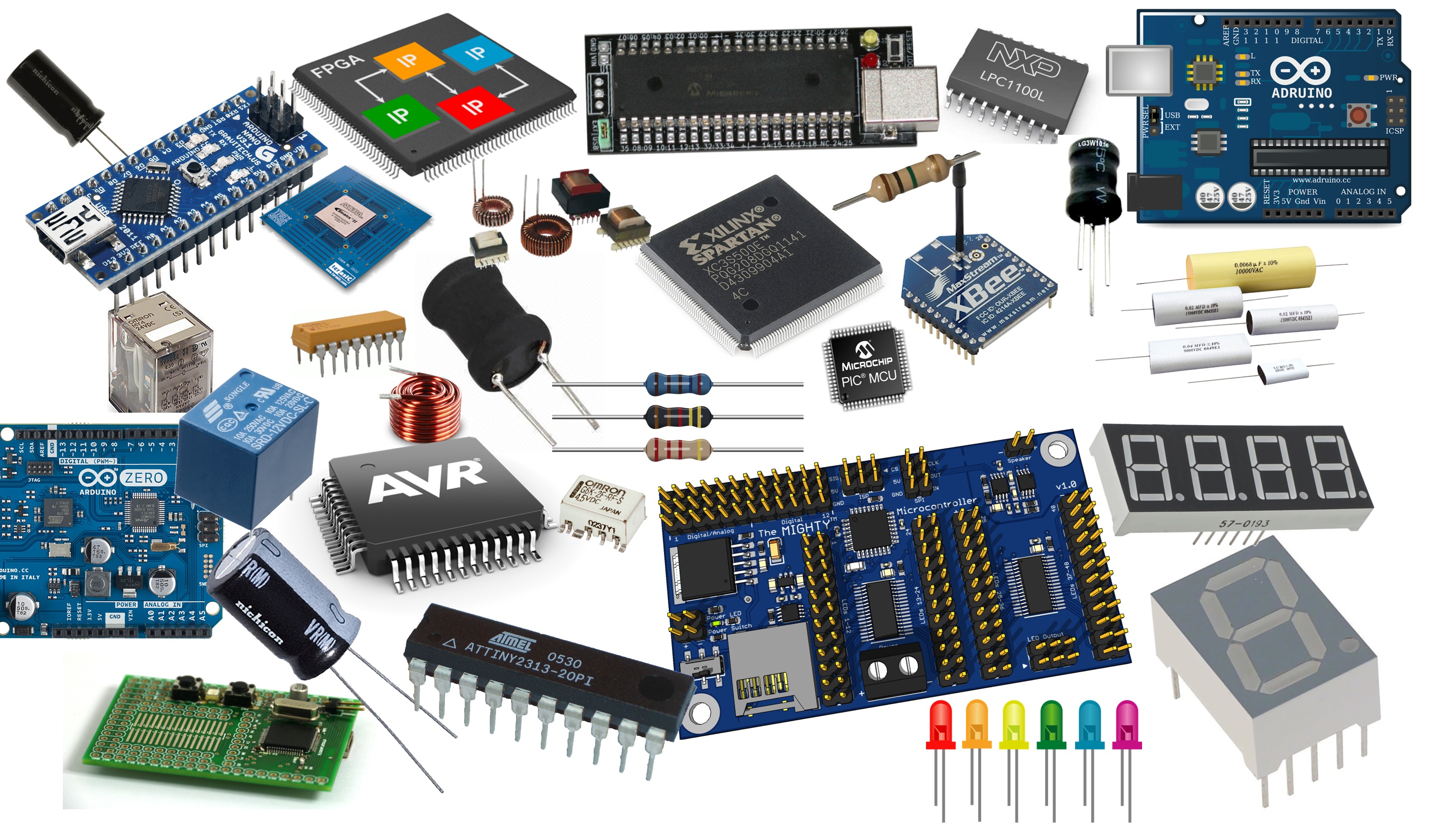

Electronic component suppliers are an essential part of the supply chain for most manufacturers. They add value and help save equipment manufacturers money by enabling them to buy the components they need, when they need them and at the quantities they want.

They also provide valuable services such as introducing new components. This is particularly important for development companies who need the latest components to develop their products and later for production runs.

In-stock inventory

Keeping a constant supply of products in stock is a vital component for many businesses. It can help them to keep up with fluctuations in demand and avoid product shortages, allowing for smooth workflow and efficient production.

For example, a pen manufacturer may build up components and supplies in the months leading up to the start of a new school year when demand is at its peak. This allows them to maintain a steady output throughout the entire school year without having to increase production time.

This is a great example of safety stock – also called buffer inventory – that helps OEMs and EMS providers ensure they have a sufficient quantity of products in stock to continue production, no matter what changes are happening in the supply chain.

Safety stock is a great way to ensure that companies are prepared for one-off events like weather or global pandemics, enabling them to remain competitive and profitable in the long run.

Faster shipping times

When it comes to electronics, manufacturers must make sure that they are able to get their parts to market in a timely manner. This is especially true with long-lead-time components, which can be hard to source in a timely fashion.

Luckily, there are a few strategies that can help mitigate these supply chain issues and keep your projects moving forward. These include building a relationship with a key distribution partner and sharing sales forecasts early and often.

A strong distributor partner has the purchasing power and network connections to quickly source in-demand components, ensuring that products are available when they are needed. They can also offer VMI programs that automatically replenish stock as needed, avoiding shortages and stockouts.

In addition, working closely with a distribution partner can shorten the time it takes to get critical components from the supply chain to the factory. Using this approach, it’s important to plan ahead for regular, recurring purchases that allow a steady stream of parts into the factory.

Better pricing

Why You need electronic component suppliers

With increasing costs and supply shortages, it’s important to work with an efficient supplier. This allows you to build a robust inventory of critical components so you can avoid costly downtime and maintain a competitive edge.

Another key benefit of working with distributors is their ability to source hard-to-find components. They are part of a global supply chain and can find specialized electronic parts that you may not be able to order directly from the manufacturer.

The cost of raw materials and labor continue to increase, causing manufacturers to raise their prices. The COVID-19 pandemic, which affected many production zones worldwide, also exacerbated the issue of supply shortages and increased inflationary pressure.

Although national leaders and central banks are trying to control price hikes, this trend may not be broken anytime soon. As a result, it’s important to develop a solid pricing strategy that minimizes your risk of missing an opportunity or losing a contract.

Technical support

The best electronic component suppliers or distributors not only stock and source a wide range of components, but they also understand their nuances. In fact, they may even provide technical literature, datasheets and more through their web portal to help you stay informed during the sourcing process.

Having broad-based technical support can be just as valuable as having access to the largest inventory of a particular device. This type of support is particularly important for high-integrity components such as multilayer ceramic capacitors, diodes, transistors and resistors.

A great technical component distributor will have a dedicated product support team, often with engineers who are trained by manufacturers. These people can be invaluable if a problem is found during the design process. They can also provide the most efficient way to get the most out of your components. This is the reason that many companies are opting to use distributors instead of manufacturers. It can save you time, money and hassle.

No comments yet