A good aluminum extrusion supplier will have excellent customer service. They will respond quickly to claims, be well-stocked and provide educational resources for consumers.

A flexible manufacturing system (FMS) is a modular system that can be adjusted to meet the needs of your project. These systems are typically used in car production lines.

Price

Aluminum extrusions allow designers to create almost any shape imaginable at cost-effective rates. They can also be recycled endlessly without any debasement of their inherent properties.

These profiles can be shaped to your exact specifications and are fabricated with precise tolerances. That way, you can minimize secondary joining processes and reduce the number of parts in your finished product.

This type of flexibility allows manufacturers to respond more quickly to market changes and keep up with customer demands for customization. It can also help improve the overall productivity of the manufacturing process.

Another factor that can influence the price of custom aluminum extrusions is the metal cost. This can be affected by political events in countries that produce or smelt aluminum and by environmental restrictions placed on these factories. However, this is easier to predict than labor costs since it tends to remain relatively stable. A good supplier will be able to provide you with accurate quotes based on the latest metal prices from LME and MCX.

Quality

Aluminum extrusions are lightweight, strong, durable, low-maintenance, and corrosion-resistant. They also offer designers almost unlimited design flexibility at cost-effective rates. Additionally, they can be recycled infinitely with no physical degradation. This makes them the ideal choice for modern industrial applications.

A flexible manufacturing system’s technical flexibility comes from its ability to quickly change the routing and sequence of operations within a parts envelope. It also involves the ability to handle changes in product requirements and production schedules.

It’s important to select a flexible manufacturing company that can provide high-quality aluminum extrusions and machining services. Look for companies that have a reputation for superior customer service, advanced facilities, and competitive pricing. They should be able to meet the needs of any industry and provide quick turnaround.

A reliable aluminum extrusion supplier will have a variety of fabrication capabilities, including anodizing, powder coating, cutting, drilling, tapping, CNC machining, and assembly. They will also offer custom designs and prototypes.

Reliability

Aluminum extrusions are a versatile and cost-effective option for manufacturing a wide variety of products. They are resistant to corrosion, a good conductor of heat and electricity, and can be easily formed and machined. They also have a high strength-to-weight ratio and can be recycled without losing any of their original physical properties.

Flexible manufacturing allows companies to adapt quickly to changing market demands, increase personalization of their product lines, and keep up with customer demand for faster turnaround times. Using flexible manufacturing techniques can help companies gain a competitive advantage over their competitors and survive in today’s fast-paced economy.

In addition to offering flexible manufacturing, the top aluminum extrusion suppliers also provide other services, such as painting, anodizing, machining, cutting, tapping, fabrication, assembly, and welding. They can also assist with the development of new designs and offer a range of custom extrusion options. They also offer services such as digital invoices and E-way bills, and speedy registrations for metal trading.

Additional Services

A flexible manufacturing system is a type of factory that can produce small batches of product based on consumer demand. The goal is to deliver precise consumer value with greater speed and accuracy than traditional factories.

A key feature of a flexible manufacturing system is the ability to adapt to different product specifications without changing equipment. This is beneficial for companies that require flexibility in their production processes because it allows them to quickly switch between products without losing quality or wasting time.

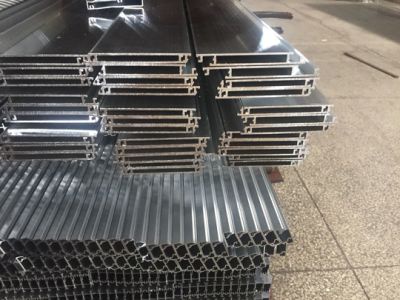

Custom manufacturer of large aluminum extrusions including curved, frosted, flame retardant and dual durometer shapes. Capabilities include cutting, drilling, tapping, forming and bending. Secondary services include packaging, welding and painting. Serves aerospace, automotive, building, communication, electrical, marine and medical industries. CAD/CAM and SolidWorks files accepted. Vendor managed inventory and JIT delivery available. Meets ANSI, ASTM and ISO standards.

No comments yet