Introduction

When it comes to lifting and transporting massive loads, safety and reliability are paramount. In industries such as construction, manufacturing, and heavy machinery, the use of the right equipment can mean the difference between a successful operation and a potentially dangerous accident. Among the indispensable tools for these applications, 4-leg chain slings have emerged as the ultimate solution for safely handling massive loads. In this article, we will delve into the world of 4 leg chain sling, exploring their design, advantages, applications, and the benefits they offer in ensuring safety and efficiency.

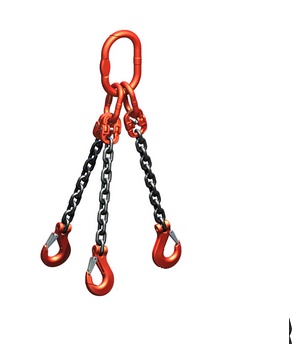

4-Leg Chain Slings: A Closer Look

A 4-leg chain sling is a versatile and robust lifting device primarily designed to hoist and secure extremely heavy loads. Its design consists of four individual chain legs, each connected to a common master link or connecting link at the top. These chain legs are typically of equal length and terminate in hooks, shackles, or other end fittings, allowing them to be securely attached to the load.

Key components of a 4-leg chain sling:

-

Chain Legs: The primary load-bearing components of the sling are the four chain legs, which are usually made from alloy steel for exceptional strength and durability.

-

Master Link: The master link is a reinforced metal link at the top of the sling, serving as the point of attachment to the lifting equipment, such as a crane hook or hoist.

-

End Fittings: Each chain leg ends with an end fitting, which can vary based on the specific application. Common end fittings include hooks, shackles, and grab hooks.

-

Load Bearing Capacity: The capacity of a 4-leg chain sling is determined by its design and the material properties of the chain. Slings are typically rated for specific weight limits.

Now, let's explore why 4-leg chain slings have become the preferred choice for safely handling massive loads.

Advantages of 4-Leg Chain Slings

-

Even Load Distribution: One of the key advantages of 4-leg chain slings is their ability to evenly distribute the load across all four legs. This ensures that the weight is balanced, reducing the risk of uneven stress and potential load shifting.

-

Exceptional Strength: Chain slings are known for their robust construction, making them suitable for heavy-duty lifting. They can handle substantial loads with ease, providing a high level of safety and reliability.

-

Durability: Made from alloy steel, 4-leg chain slings are resistant to wear, corrosion, and extreme environmental conditions. This durability ensures a long service life, even in harsh industrial settings.

-

Customization: Chain slings can be customized to fit the specific needs of an application. This includes selecting the appropriate chain size, end fittings, and length, ensuring compatibility with different loads and lifting equipment.

-

Versatility: These slings are versatile and can be used in various industries, including construction, manufacturing, shipbuilding, and mining, for a wide range of applications.

-

Safety Features: Many 4-leg chain slings are equipped with safety features such as self-locking hooks and safety latches to prevent accidental load detachment.

-

Ease of Inspection: Chain slings are relatively easy to inspect for wear and damage, ensuring that they remain safe for use. Routine inspections are crucial to their longevity and safety.

Applications of 4-Leg Chain Slings

4-leg chain slings find applications in a variety of industries and scenarios due to their versatility and capacity to handle heavy loads safely. Some common applications include:

-

Construction: Chain slings are used for lifting steel beams, concrete blocks, and other construction materials at building sites.

-

Manufacturing: In manufacturing plants, these slings assist in moving heavy machinery and equipment during assembly or maintenance.

-

Mining: Chain slings play a crucial role in the mining industry, where they are employed to hoist heavy ore loads, equipment, and machinery.

-

Shipbuilding: Building large vessels requires the precise positioning of heavy components, which is facilitated by 4-leg chain slings.

-

Agriculture: In agricultural settings, these slings are used for tasks such as lifting and transporting irrigation equipment, large bales of hay, and machinery.

-

Material Handling: Warehouses and distribution centers utilize chain slings to move and stack heavy pallets and goods efficiently.

-

Oil and Gas: In the oil and gas industry, chain slings are used for handling drilling equipment and transporting heavy pipes and components.

Benefits of Using 4-Leg Chain Slings

Now, let's delve deeper into the specific benefits that 4-leg chain slings offer for safely handling massive loads:

1. Superior Load Distribution: The four-leg design ensures that the load is evenly distributed, reducing the risk of overload on any individual chain leg. This balanced distribution enhances safety and stability during lifting operations.

2. High Weight Capacity: 4-leg chain slings are capable of handling extremely heavy loads, making them indispensable in industries where large and weighty objects need to be moved or lifted.

3. Durability and Longevity: Constructed from alloy steel, these slings are highly durable and resistant to wear and tear. They are built to withstand the rigors of heavy industrial use, ensuring a long service life.

4. Versatility: 4-leg chain slings are versatile tools that can be adapted to various load shapes and sizes. The ability to customize end fittings and chain lengths makes them suitable for a wide range of applications.

5. Safety Features: Many chain slings are equipped with safety features such as self-locking hooks and safety latches, adding an extra layer of security during lifting operations.

6. Ease of Inspection: Regular inspection of chain slings is relatively straightforward, allowing for the early detection of wear, damage, or fatigue. This proactive approach to maintenance enhances safety.

7. Compliance with Regulations: Using 4-leg chain slings that meet industry and regulatory standards ensures that lifting operations comply with safety and legal requirements.

Conclusion

In industries where the safe handling of massive loads is paramount, 4-leg chain slings have emerged as the ultimate solution. Their even load distribution, exceptional strength, durability, customization options, and safety features make them indispensable tools in construction, manufacturing, mining, and various other sectors.

The benefits of using 4-leg chain slings extend beyond load capacity; they contribute to safer and more efficient lifting operations, protecting both personnel and valuable equipment. As a testament to their versatility and reliability, 4-leg chain slings continue to play a vital role in the heavy lifting needs of industries worldwide, ensuring that massive loads are moved with precision and safety.

No comments yet