Introduction

In the world of heavy lifting and rigging, safety is of paramount importance to protect both personnel and valuable cargo. Safety slings are indispensable tools used to secure and lift heavy loads in a wide range of industries. This article delves into the various types of safety slings for lifting, highlighting their secure and reliable features that ensure optimal safety during lifting operations.

Understanding Safety Slings for Lifting

Safety slings are flexible, durable, and load-bearing devices designed to lift and support heavy objects safely. These slings are typically made from materials like nylon, polyester, wire rope, or chain, each with specific applications and load capacities. Safety slings come in various configurations, such as single-leg, double-leg, and endless loop, to suit different lifting requirements.

Types of Safety Slings

2.1. Nylon Slings

Nylon slings are popular due to their high strength, flexibility, and resistance to abrasion. They are particularly well-suited for delicate loads as they provide a soft, non-scratching surface. Nylon slings are also known for their stretchability, which helps absorb shock during lifting and protects both the sling and the load from sudden impacts.

2.2. Polyester Slings

Polyester slings are prized for their low stretch, making them ideal for applications where minimal elongation is required. These slings are resistant to UV rays, chemicals, and moisture, ensuring long-lasting performance even in harsh environments. Polyester slings offer excellent load stability and are often used in precision lifting operations.

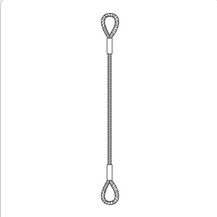

2.3. Wire Rope Slings

Wire rope slings are constructed from high-strength steel wires woven into various configurations, such as single-part, multi-part, or braided slings. These slings are exceptionally durable and have high temperature resistance, making them suitable for heavy-duty lifting in extreme conditions. Wire rope slings are commonly used in industries like construction, mining, and oil and gas.

2.4. Chain Slings

Chain slings consist of welded chains with hooks or attachments at each end. They are renowned for their superior strength and durability, capable of withstanding high temperatures and harsh environments. Chain slings are often used in rugged industries like steel manufacturing and heavy machinery handling.

Benefits of Safety Slings for Lifting

3.1. Enhanced Load Security

Safety slings provide a secure and reliable means of lifting heavy loads. The diverse material options allow users to select the most appropriate sling type for their specific application, ensuring the load is securely held throughout the lifting process. This reduces the risk of load drops, enhancing overall safety for both the workers and the surrounding environment.

3.2. Damage Prevention

Safety slings are designed with protective features to minimize damage to the load being lifted. Materials like nylon and polyester offer a soft and non-abrasive surface, ensuring that the sling does not scratch or mar delicate surfaces. This safeguard is especially crucial when handling valuable, sensitive, or precision equipment.

3.3. Flexibility and Versatility

Different types of safety slings cater to a wide range of lifting requirements, making them versatile tools in various industries. The flexibility of safety slings allows for easy maneuvering and adapting to complex load shapes, ensuring a smooth and efficient lifting process even in challenging lifting scenarios.

3.4. Weight Reduction

Compared to traditional lifting methods, safety slings are lightweight and easy to transport. This weight reduction not only makes them more manageable for workers but also contributes to reducing the overall load weight during lifting, providing an added safety margin.

3.5. Cost-Effectiveness

Safety slings offer a cost-effective solution for heavy lifting needs. They are durable and long-lasting, minimizing the need for frequent replacements and reducing maintenance costs. Moreover, the enhanced safety they provide helps prevent potential accidents and associated costs, such as injuries or damaged cargo.

Top Applications of Safety Slings

4.1. Construction and Infrastructure

Safety slings are extensively used in construction and infrastructure projects to lift and position heavy building materials, such as steel beams, concrete blocks, and precast elements. Their versatility and load security are particularly valuable in complex construction sites with various lifting requirements.

4.2. Manufacturing and Warehousing

In manufacturing and warehousing industries, safety slings are utilized for handling heavy machinery, equipment, and raw materials. The ability of safety slings to protect sensitive surfaces and adapt to irregularly shaped loads makes them essential tools in maintaining operational efficiency and safety.

4.3. Shipping and Maritime

Safety slings play a crucial role in shipping and maritime applications, where loading and unloading cargo onto ships and vessels demand secure lifting solutions. Nylon and polyester slings are commonly used to safeguard delicate or valuable goods during transportation.

4.4. Mining and Oil & Gas

Industries like mining and oil & gas require heavy-duty lifting solutions to handle equipment and components in harsh environments. Wire rope and chain slings are often preferred for their robustness and resistance to extreme conditions, ensuring safe and efficient lifting operations.

Conclusion

Safety slings for lifting are indispensable tools in ensuring secure and reliable heavy lifting operations. With various types of slings available, including nylon, polyester, wire rope, and chain slings, there is a suitable option for every lifting requirement.

The benefits of safety slings, such as enhanced load security, damage prevention, flexibility, weight reduction, and cost-effectiveness, make them essential components across diverse industries. From construction and manufacturing to shipping and mining, safety slings play a crucial role in safeguarding personnel and valuable cargo during lifting tasks.

In conclusion, investing in top-quality safety slings for lifting is a prudent choice for any industry that deals with heavy loads. These slings not only improve lifting performance but also ensure the safety of workers, equipment, and the surrounding environment, thereby contributing to a safer and more efficient workplace.

No comments yet