Introduction

In industries where lifting and rigging operations are a common occurrence, ensuring safety is paramount. The equipment used in these operations must not only be robust but also designed to withstand heavy loads and harsh environments. Stainless steel wire rope slings have emerged as a critical component in such applications, guaranteeing secure and safe lifting operations. In this article, we will explore the significance of stainless steel wire rope slings, their design, functionalities, benefits, and how they contribute to a safer working environment.

Understanding Stainless Steel Wire Rope Slings

Stainless steel wire rope slings are versatile and durable lifting accessories that find extensive use in various industries, including construction, maritime, manufacturing, and material handling. These slings consist of multiple strands of stainless steel wires that are twisted together to form a sturdy rope. They are then fitted with end fittings and attachments, such as hooks or shackles, to facilitate connection to the load and lifting equipment.

Key Features and Design

Stainless steel wire rope slings are characterized by several key features and design elements that make them ideal for lifting operations:

-

Stainless Steel Construction: The use of stainless steel as the primary material ensures high corrosion resistance, making these slings suitable for use in challenging environments, including marine and offshore settings.

-

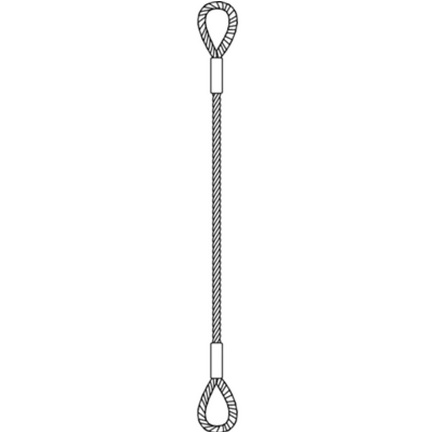

Multiple Configurations: Stainless steel wire rope slings are available in various configurations, such as single-leg, two-leg, three-leg, and four-leg, to accommodate different load shapes and weights.

-

Thimble and Sleeve Protection: These slings often include thimbles and sleeves at the eyes to protect against wear and tear, extending their service life.

-

Lifting Eyes: Stainless steel slings are equipped with lifting eyes that allow for easy attachment to hooks, shackles, or other lifting hardware.

-

Load Ratings: Each sling is rated for a specific load capacity, ensuring that it is used within its safe working limits.

-

Flexibility: Stainless steel wire rope slings are flexible, allowing for easy maneuvering and positioning of the load during lifting.

-

Durability: Stainless steel is known for its high strength and durability, ensuring that these slings can withstand heavy loads and rigorous use.

Functionality of Stainless Steel Wire Rope Slings

Stainless steel wire rope slings serve a crucial role in lifting operations due to their unique functionality. Here's how they enhance safety and efficiency:

-

Load Distribution: The multiple strands of stainless steel wires distribute the load evenly across the sling, reducing the risk of overstressing any single part of the sling. This ensures a safer lifting operation.

-

Corrosion Resistance: Stainless steel's inherent corrosion resistance allows these slings to be used in environments where exposure to moisture, saltwater, or chemicals would degrade other materials. This is particularly beneficial in maritime and offshore applications.

-

Flexibility and Maneuverability: Stainless steel wire rope slings are highly flexible, allowing for precise load positioning and maneuverability. This is crucial when dealing with irregularly shaped or fragile loads.

-

High Strength-to-Weight Ratio: Stainless steel is renowned for its exceptional strength-to-weight ratio, enabling these slings to handle heavy loads while remaining relatively lightweight.

-

Long Service Life: The combination of stainless steel's durability and the protective thimbles and sleeves results in a long service life for these slings, reducing replacement costs.

Benefits of Stainless Steel Wire Rope Slings

-

Safety Above All: The primary benefit of using stainless steel wire rope slings is the enhancement of safety in lifting operations. Their strength, flexibility, and corrosion resistance ensure that loads can be lifted and maneuvered securely, minimizing the risk of accidents, damage, or injuries.

-

Versatility: Stainless steel wire rope slings are versatile and adaptable to a wide range of lifting scenarios. They are suitable for both indoor and outdoor applications and can handle diverse load shapes and sizes.

-

Durability and Cost Efficiency: While stainless steel wire rope slings may have a higher initial cost compared to other materials, their longevity and resistance to corrosion translate into cost savings over time. They require fewer replacements and maintenance, making them a cost-efficient choice.

-

Compliance with Industry Standards: These slings are manufactured and tested to meet industry-specific standards and regulations, ensuring that lifting operations are compliant and safe.

-

Environmental Resilience: Stainless steel wire rope slings are an environmentally friendly option due to their durability and recyclability, reducing waste in the long run.

-

Enhanced Workplace Efficiency: The flexibility and ease of use of stainless steel wire rope slings improve workplace efficiency by allowing for faster and more precise load handling.

Conclusion

In conclusion, stainless steel wire rope slings are indispensable assets in industries that require secure and safe lifting operations. Their robust construction, corrosion resistance, flexibility, and load distribution capabilities make them the go-to choice for lifting and rigging applications. By choosing stainless steel wire rope slings, organizations prioritize safety above all else, reduce maintenance costs, and enhance workplace efficiency.

In a world where safety regulations and environmental concerns are at the forefront of industry practices, stainless steel wire rope slings offer a reliable and sustainable solution for lifting and rigging needs. Their versatility and long service life make them a smart investment, ensuring that lifting operations can be conducted with the utmost confidence in safety and efficiency.

No comments yet